'69 Barracuda T56 swap, floor, cross member

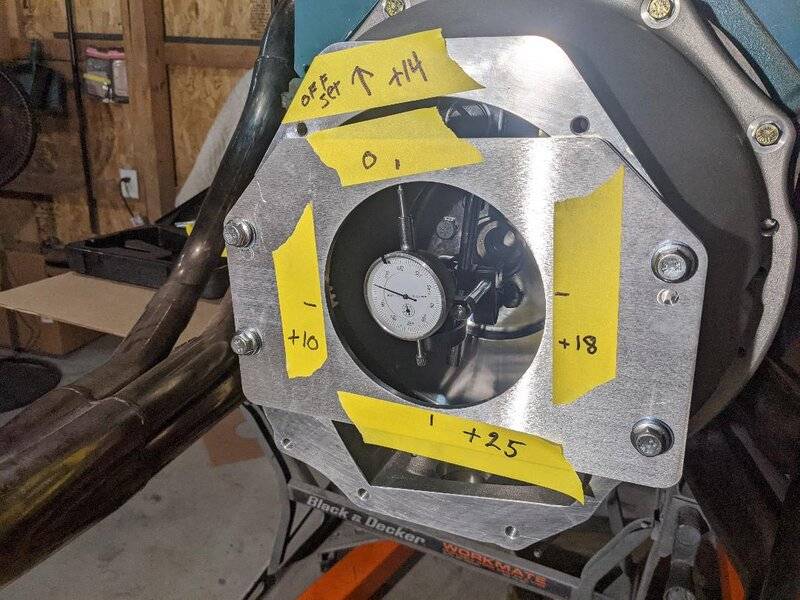

Took wire wheel in drill and cleaned rear mating surface of block and crank surface. Very light pressure and the paint and surface rust came right off quickly. Then lightly went over with 180 grit sand paper. Flywheel torqued to 55 ft/pds and bellhousing 30 ft/pds cross tightened. Mounted dial on flywheel and looks like I need .014" offset dowel pins to move it up and slightly to the left. Afterwards put engine down on blocks since hoist tends to bleed down over time not safe to leave up on table.

Took wire wheel in drill and cleaned rear mating surface of block and crank surface. Very light pressure and the paint and surface rust came right off quickly. Then lightly went over with 180 grit sand paper. Flywheel torqued to 55 ft/pds and bellhousing 30 ft/pds cross tightened. Mounted dial on flywheel and looks like I need .014" offset dowel pins to move it up and slightly to the left. Afterwards put engine down on blocks since hoist tends to bleed down over time not safe to leave up on table.