The importance of measuring bell housing runout.

Tomorrow morning we're going to bolt up the TKX bell to a 440 that Greg has secured to a stand. If the runout is consistent then we know its the bell. I'm actually more concerned that the bell will fall in spec. That means something is off with the engine.

The engine mating surface has been cleaned and prepped. Initially there was a tiny metal booger, created when something slammed into the side of the engine and dented the mounting flange. I filed down the protrusion and smoothed the surface with crocus cloth.

Next, I found a hairline cut (not a crack) at about 2:00 on the mounting flange. It was a clean cut, but a very slight ridge had built up the length of the cut. Again, it was filed down and sanded smooth. No doubt those two imperfections led to the .082" / .041" TIR measured earlier in the week.

Post prepping of the engine mating surface got the measurement down to yesterday's .048" / .024" measurement. But then today's measurements set the process back to square one.

Dent:

Hairline cut

Hairline cut after filing

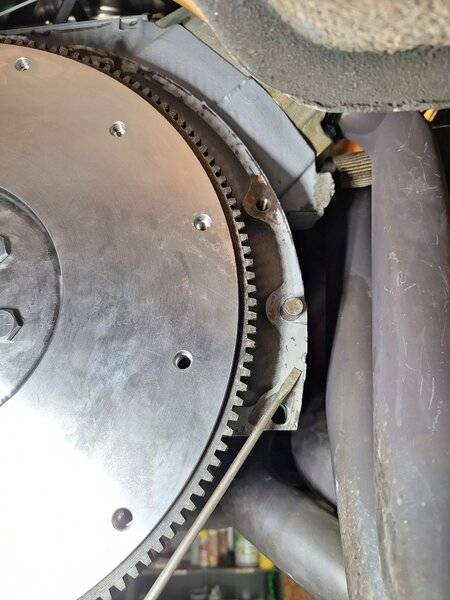

Engine mounting surface fully prepped

Tomorrow morning we're going to bolt up the TKX bell to a 440 that Greg has secured to a stand. If the runout is consistent then we know its the bell. I'm actually more concerned that the bell will fall in spec. That means something is off with the engine.

The engine mating surface has been cleaned and prepped. Initially there was a tiny metal booger, created when something slammed into the side of the engine and dented the mounting flange. I filed down the protrusion and smoothed the surface with crocus cloth.

Next, I found a hairline cut (not a crack) at about 2:00 on the mounting flange. It was a clean cut, but a very slight ridge had built up the length of the cut. Again, it was filed down and sanded smooth. No doubt those two imperfections led to the .082" / .041" TIR measured earlier in the week.

Post prepping of the engine mating surface got the measurement down to yesterday's .048" / .024" measurement. But then today's measurements set the process back to square one.

Dent:

Hairline cut

Hairline cut after filing

Engine mounting surface fully prepped