TF & Speedmaster Flow Tests

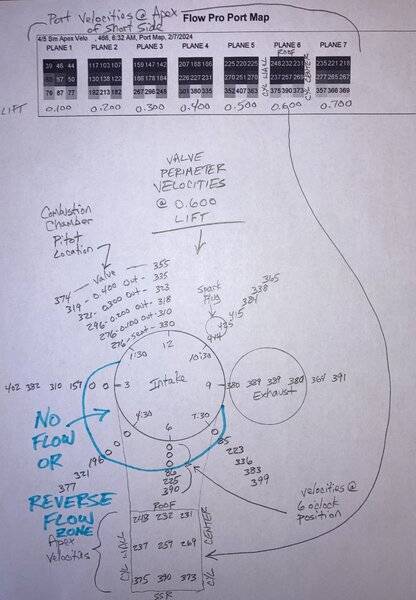

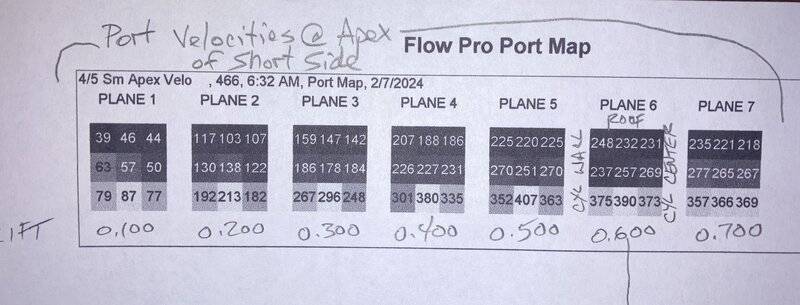

Across the top of the second attachment are the corresponding port velocities at the apex for the different valve lifts. The second attachment shows the port and chamber looking down from above, so the 3 oclock and 9 oclock positions are opposite of the drawings in the earlier posts.

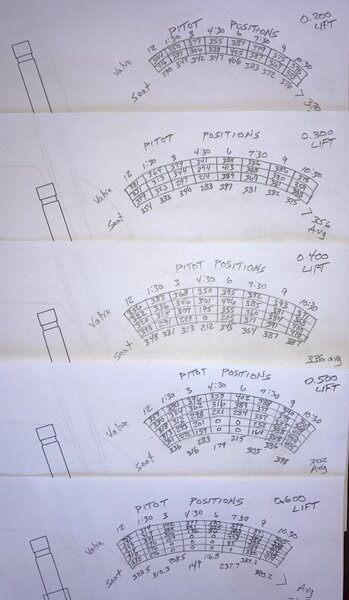

This attachment might be hard to see. All is good at 0.200, there are signs at 0.300, the first zero shows up at 0.400.

Across the top of the second attachment are the corresponding port velocities at the apex for the different valve lifts. The second attachment shows the port and chamber looking down from above, so the 3 oclock and 9 oclock positions are opposite of the drawings in the earlier posts.