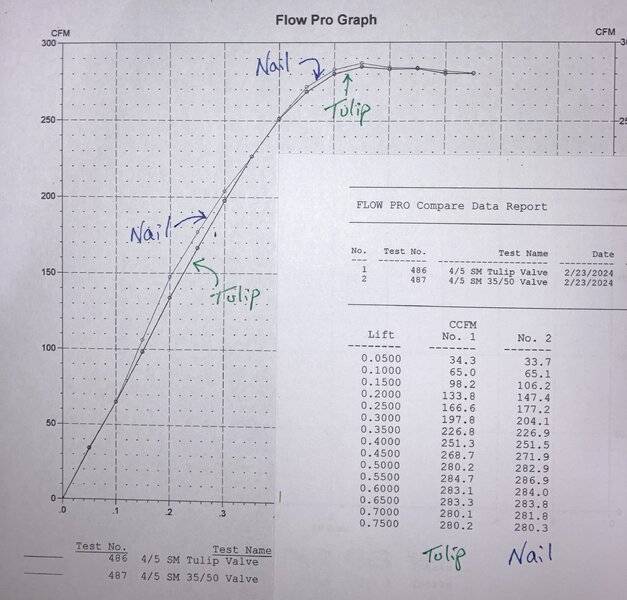

TF & Speedmaster Flow Tests

This is a test I've been wanting to try for a while, but just getting to it. This test is in a Speedmaster head with 50 degree seats and 35 degree top cut. Valves were sunk 0.090" to acheive the top cut.

I have been struggling with flow backing up in the port starting at 0.550-0.600 lift. Pitot testing revealed that the flow is separating from the SS starting at 0.400 lift (380 fps SS floor velocity) and getting progressively worse as lift increases.

I will stop here and say that PBR told me a couple of months ago to increase the area at the apex and get the velocity down and that is probably the real solution, but I don't listen so here we are. Momma always said if I had been her first child I would have been her last.

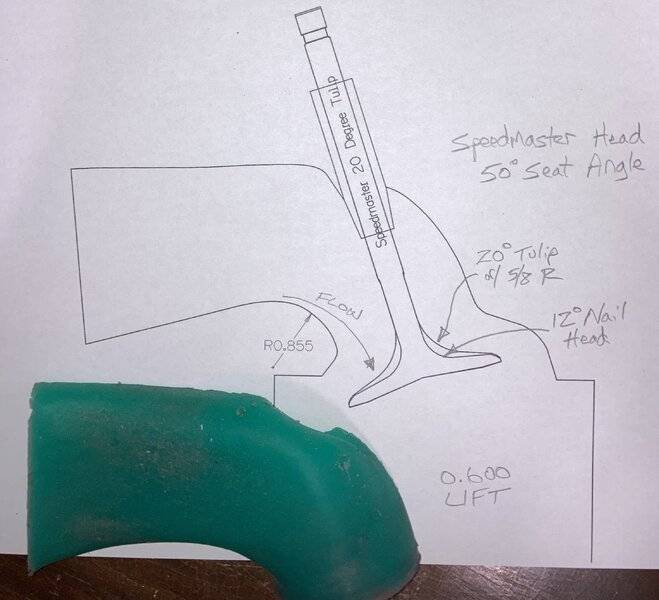

I have been thinking of other ways to keep the flow attached to the SS at higher lifts. I have been wondering how a tulip valve would help on the short side. It's not easy to find tulip intake valves, so I ended up fabricating one with epoxy. Now I know that overall a tulip valve is not the way to go, but I am looking for a solution that helps one localized area, not the entire port. This is a learning exercise. Look at the drawing below. Surely air coming over the short side would benefit from a tulip shape to help it make the turn. Surely. Air would ease around the turn and not hit the brick wall straight on.

But, as can be seen from the flow results, the tulip is the overall loser. Even when I measured localized velocities around the perimeter of the valve from the combustion chamber side, the tulip never clearly helped. I thought there would be somewhere in the flow curve and some localized area that significantly benefitted from the shape of the tulip. Not really. There are a few areas around the valve that respond favorably at some lift points, but there are no real positive trends for the tulip.

This is just another case of the flow bench proving my intuition to be wrong. It happens frequently. Guess I should have known since it was so hard to find a tulip valve.

This is a test I've been wanting to try for a while, but just getting to it. This test is in a Speedmaster head with 50 degree seats and 35 degree top cut. Valves were sunk 0.090" to acheive the top cut.

I have been struggling with flow backing up in the port starting at 0.550-0.600 lift. Pitot testing revealed that the flow is separating from the SS starting at 0.400 lift (380 fps SS floor velocity) and getting progressively worse as lift increases.

I will stop here and say that PBR told me a couple of months ago to increase the area at the apex and get the velocity down and that is probably the real solution, but I don't listen so here we are. Momma always said if I had been her first child I would have been her last.

I have been thinking of other ways to keep the flow attached to the SS at higher lifts. I have been wondering how a tulip valve would help on the short side. It's not easy to find tulip intake valves, so I ended up fabricating one with epoxy. Now I know that overall a tulip valve is not the way to go, but I am looking for a solution that helps one localized area, not the entire port. This is a learning exercise. Look at the drawing below. Surely air coming over the short side would benefit from a tulip shape to help it make the turn. Surely. Air would ease around the turn and not hit the brick wall straight on.

But, as can be seen from the flow results, the tulip is the overall loser. Even when I measured localized velocities around the perimeter of the valve from the combustion chamber side, the tulip never clearly helped. I thought there would be somewhere in the flow curve and some localized area that significantly benefitted from the shape of the tulip. Not really. There are a few areas around the valve that respond favorably at some lift points, but there are no real positive trends for the tulip.

This is just another case of the flow bench proving my intuition to be wrong. It happens frequently. Guess I should have known since it was so hard to find a tulip valve.