Vacuum Secondary Conversion

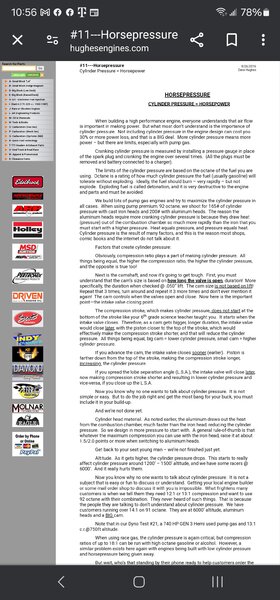

Here is the snip from hughes that I wanted to post earlier, but couldn't find. It is more to do with cylinder pressure, but does bring cylinder head materia in it too.

Perhaps it is a guide that is no longer relevant, the 165 for cast vs the 195 recommendations for aluminum heads, but probably one I will continue to adhere to until I see better information.

Anyway, I don't want to take over the op's thread on vacuum secondaries/distributors.

I was just hoping for clarification for my own benefit on cylinder pressure.

Perhaps someone will start a thread on cylinder head material vs cylinder pressure and people can post what they are running on what.

Unfortunately, I do remember engine building back in the 70's/80's/90's.

Here is the snip from hughes that I wanted to post earlier, but couldn't find. It is more to do with cylinder pressure, but does bring cylinder head materia in it too.

Perhaps it is a guide that is no longer relevant, the 165 for cast vs the 195 recommendations for aluminum heads, but probably one I will continue to adhere to until I see better information.

Anyway, I don't want to take over the op's thread on vacuum secondaries/distributors.

I was just hoping for clarification for my own benefit on cylinder pressure.

Perhaps someone will start a thread on cylinder head material vs cylinder pressure and people can post what they are running on what.

Unfortunately, I do remember engine building back in the 70's/80's/90's.