what rods would be better for my build

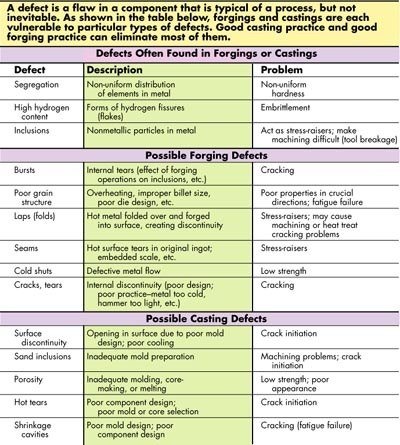

Dave, you better clarified that for me. My understanding was with a forged part, the molten metal was cast, and pressurized as it cooled. Not starting as a base shape, ingot, billet, whatever, then hammered hot or cold into the final shape. I'm attaching a chart of possible defects..They are talking about valves, but same concept. The issues was poor dies/quality control (from teh Chinese industrial environment) resulting in grain flaws in the beams of the rods. I call them casting flaws..That's wrong as you pointed out. And like I said, not all rods, not every part..Only some. I agree anything can be broken, and they will work a little better than a stock rod, I just dont want to risk a problem due to something I cant see or resonably inspect for.

Dave, you better clarified that for me. My understanding was with a forged part, the molten metal was cast, and pressurized as it cooled. Not starting as a base shape, ingot, billet, whatever, then hammered hot or cold into the final shape. I'm attaching a chart of possible defects..They are talking about valves, but same concept. The issues was poor dies/quality control (from teh Chinese industrial environment) resulting in grain flaws in the beams of the rods. I call them casting flaws..That's wrong as you pointed out. And like I said, not all rods, not every part..Only some. I agree anything can be broken, and they will work a little better than a stock rod, I just dont want to risk a problem due to something I cant see or resonably inspect for.