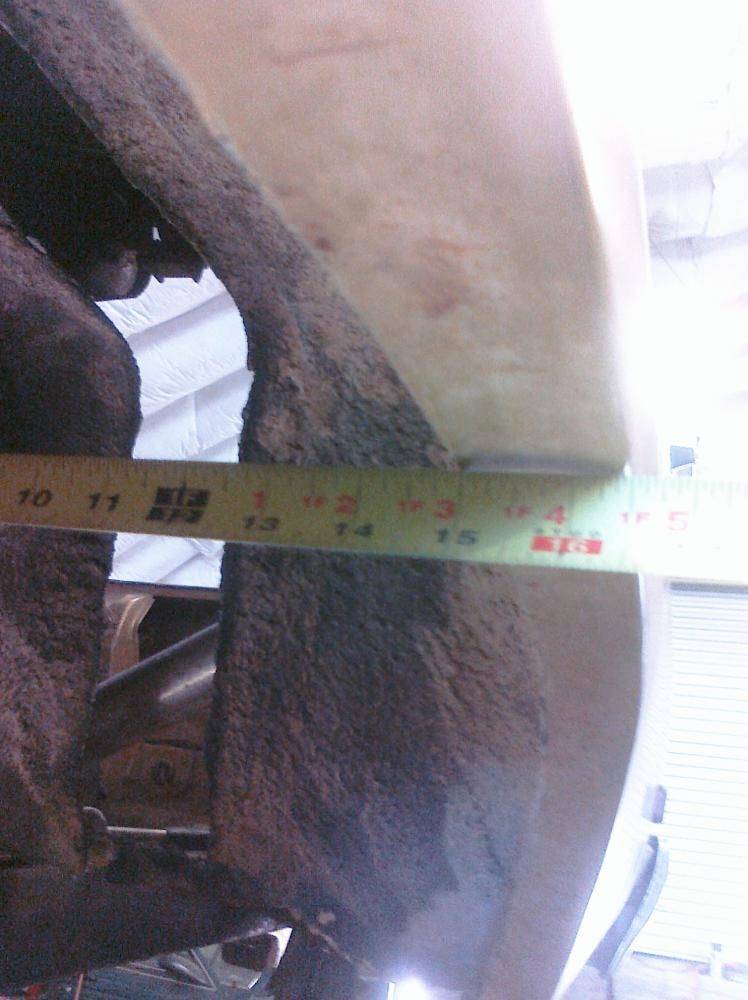

67 Dart Build Triangulated 4 link & Mini Tub

EDIT: i have the pics here at work too.....

i get what your saying but im not cutting the tubs all the way to the rail im leaving the pince weld, and them bending it up and welding the inner fender to that. (ill have pics up later today)

EDIT: i have the pics here at work too.....