General Description

hi Y'all

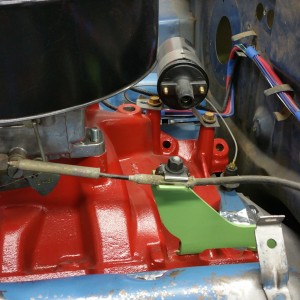

my old crusty cuda. yep she's seen better days. only 61,000 on the odometer. and with her last registered in 1981 its probably true mileage. its amazing what a mess 30 years of sitting exposed to the elements and careless ownership does to a vehicle.

i replaced the ganked up floors and cut thru rear torsion bar crossmember where somebody torched a nasty hole to make a home brewed floor shift setup. used a floor and crossmember from my 74 dart parts car. i built up a set of cordoba...

my old crusty cuda. yep she's seen better days. only 61,000 on the odometer. and with her last registered in 1981 its probably true mileage. its amazing what a mess 30 years of sitting exposed to the elements and careless ownership does to a vehicle.

i replaced the ganked up floors and cut thru rear torsion bar crossmember where somebody torched a nasty hole to make a home brewed floor shift setup. used a floor and crossmember from my 74 dart parts car. i built up a set of cordoba...

You do not have permission to view the full content of this item.

Log in or register now.

-

i17063.jpg60.4 KB · Views: 972

i17063.jpg60.4 KB · Views: 972 -

i17064.jpg43.3 KB · Views: 294

i17064.jpg43.3 KB · Views: 294 -

i17066.jpg43.3 KB · Views: 291

i17066.jpg43.3 KB · Views: 291 -

i17068.jpg46.9 KB · Views: 286

i17068.jpg46.9 KB · Views: 286 -

i17331.jpg44.2 KB · Views: 250

i17331.jpg44.2 KB · Views: 250 -

i17332.jpg40.9 KB · Views: 231

i17332.jpg40.9 KB · Views: 231 -

i17387.jpg44.7 KB · Views: 274

i17387.jpg44.7 KB · Views: 274 -

i17623.jpg41.4 KB · Views: 294

i17623.jpg41.4 KB · Views: 294 -

i17624.jpg42.7 KB · Views: 253

i17624.jpg42.7 KB · Views: 253 -

i17847.jpg36.4 KB · Views: 281

i17847.jpg36.4 KB · Views: 281 -

i17848.jpg48.9 KB · Views: 277

i17848.jpg48.9 KB · Views: 277 -

i18257.jpg36.2 KB · Views: 251

i18257.jpg36.2 KB · Views: 251 -

i18362.jpg42.6 KB · Views: 263

i18362.jpg42.6 KB · Views: 263 -

i18445.jpg41.6 KB · Views: 264

i18445.jpg41.6 KB · Views: 264 -

i18446.jpg39.1 KB · Views: 241

i18446.jpg39.1 KB · Views: 241 -

i19443.jpg36.4 KB · Views: 261

i19443.jpg36.4 KB · Views: 261 -

i19731.jpg34.4 KB · Views: 277

i19731.jpg34.4 KB · Views: 277 -

i19732.jpg39.3 KB · Views: 256

i19732.jpg39.3 KB · Views: 256 -

i19733.jpg36.4 KB · Views: 243

i19733.jpg36.4 KB · Views: 243 -

i19734.jpg34.4 KB · Views: 243

i19734.jpg34.4 KB · Views: 243 -

i25369.jpg36.4 KB · Views: 250

i25369.jpg36.4 KB · Views: 250 -

i25370.jpg39.5 KB · Views: 262

i25370.jpg39.5 KB · Views: 262 -

i25371.jpg33.6 KB · Views: 216

i25371.jpg33.6 KB · Views: 216 -

i25374.jpg33.2 KB · Views: 291

i25374.jpg33.2 KB · Views: 291 -

i25375.jpg42.4 KB · Views: 222

i25375.jpg42.4 KB · Views: 222 -

i26176.jpg39.2 KB · Views: 256

i26176.jpg39.2 KB · Views: 256 -

i26177.jpg39.9 KB · Views: 211

i26177.jpg39.9 KB · Views: 211 -

i28781.jpg53.4 KB · Views: 232

i28781.jpg53.4 KB · Views: 232 -

i28783.jpg32.7 KB · Views: 260

i28783.jpg32.7 KB · Views: 260 -

i28784.jpg37.6 KB · Views: 227

i28784.jpg37.6 KB · Views: 227 -

i28785.jpg26.6 KB · Views: 240

i28785.jpg26.6 KB · Views: 240 -

20151126_174644.jpg1.6 MB · Views: 295

20151126_174644.jpg1.6 MB · Views: 295 -

20150331_202527.jpg1.6 MB · Views: 347

20150331_202527.jpg1.6 MB · Views: 347 -

20150415_182345.jpg1.8 MB · Views: 384

20150415_182345.jpg1.8 MB · Views: 384 -

20150801_220316.jpg1.4 MB · Views: 369

20150801_220316.jpg1.4 MB · Views: 369 -

20151007_200325.jpg1.2 MB · Views: 282

20151007_200325.jpg1.2 MB · Views: 282 -

20150910_151539.jpg1.9 MB · Views: 304

20150910_151539.jpg1.9 MB · Views: 304 -

20140901_185512.jpg517.6 KB · Views: 246

20140901_185512.jpg517.6 KB · Views: 246 -

20141106_173241.jpg619.2 KB · Views: 221

20141106_173241.jpg619.2 KB · Views: 221 -

20150201_213939.jpg671.7 KB · Views: 232

20150201_213939.jpg671.7 KB · Views: 232 -

20150110_144151.jpg599.5 KB · Views: 182

20150110_144151.jpg599.5 KB · Views: 182 -

20140815_161141.jpg410.4 KB · Views: 172

20140815_161141.jpg410.4 KB · Views: 172 -

20151123_131745.jpg1.4 MB · Views: 298

20151123_131745.jpg1.4 MB · Views: 298 -

20160604_161845.jpg1.2 MB · Views: 376

20160604_161845.jpg1.2 MB · Views: 376