Bought her back in November. Mostly a complete car, but I knew certain things needs to be upgraded and completed when I bought it. Little did I know I was going to start digging and find a sink hole! Here's how she started.

Then when I went to go and upgrade the fuel system with an electric fuel pump and 20 gallon cell is when I really found things I didn't like. Rust! My arch nemesis! I sold my last car because of too much rust and now here I am again. At least I feel like this car is worth putting the money, time and effort into unlike the last one.

Just to see what the new fuel cell looked like in there.

So I go ahead and take the interior out. Front floor pans replaced. But there was more that was covered up with epoxy and rtv sealant!

The previous owner paid for the body shop to fix this stuff and look what he got. I removed all that epoxy and discovered significant size holes underneath.

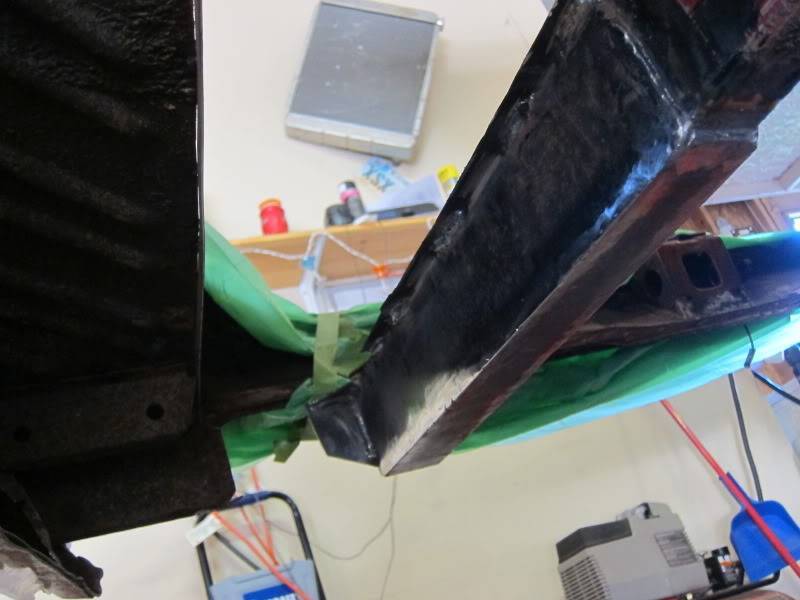

So I went to the back and continued cutting rust out. Ordered some safe-t-cap frame rails and the damn things would not fit. They sent me 2 sets and one was too wide and the other was too narrow. What really sucks is I ended up paying for a bunch of shipping on those stupid things and they wouldn't even work. Thanks a lot rust technicians for NOTHING but a waste of money. I got what I paid back but I didn't get the $50 in shipping they ripped me off for back! :wack: So I decided I would just make my own caps because I didn't need the shackle mounts anyway.

Cutting out the inner quarter skins. All kinds of crap behind there and nothing was treated. All rusty. That body guy needs a kick in the face.

Started the mini tub....

Comparing the old 235/50/15 to the 325/50/15.

Comparing the old weld wheels to the new billet specialties performer. There are only slight differences but there's just enough to say that they aren't the same.

And that's where I'm at so far. 4 link should be coming soon and in June I'll be sending her to the local shop to get a 6 point cage with swing outs installed. Should be good down to 10.00 with that. More to come later.....

Then when I went to go and upgrade the fuel system with an electric fuel pump and 20 gallon cell is when I really found things I didn't like. Rust! My arch nemesis! I sold my last car because of too much rust and now here I am again. At least I feel like this car is worth putting the money, time and effort into unlike the last one.

Just to see what the new fuel cell looked like in there.

So I go ahead and take the interior out. Front floor pans replaced. But there was more that was covered up with epoxy and rtv sealant!

The previous owner paid for the body shop to fix this stuff and look what he got. I removed all that epoxy and discovered significant size holes underneath.

So I went to the back and continued cutting rust out. Ordered some safe-t-cap frame rails and the damn things would not fit. They sent me 2 sets and one was too wide and the other was too narrow. What really sucks is I ended up paying for a bunch of shipping on those stupid things and they wouldn't even work. Thanks a lot rust technicians for NOTHING but a waste of money. I got what I paid back but I didn't get the $50 in shipping they ripped me off for back! :wack: So I decided I would just make my own caps because I didn't need the shackle mounts anyway.

Cutting out the inner quarter skins. All kinds of crap behind there and nothing was treated. All rusty. That body guy needs a kick in the face.

Started the mini tub....

Comparing the old 235/50/15 to the 325/50/15.

Comparing the old weld wheels to the new billet specialties performer. There are only slight differences but there's just enough to say that they aren't the same.

And that's where I'm at so far. 4 link should be coming soon and in June I'll be sending her to the local shop to get a 6 point cage with swing outs installed. Should be good down to 10.00 with that. More to come later.....