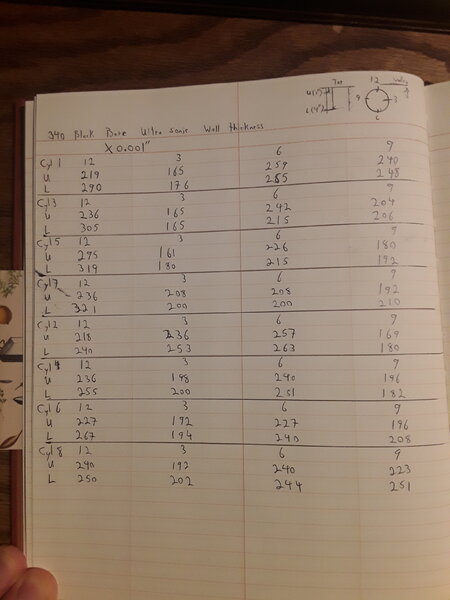

I measured my 340 block for wall thickness using an ultrasonic thickness tester I bought off of Amazon. It a cheap Chinese unit, but seems to work ok on cast iron. I dont have any delusions that this gauge will give my super accurate results, but it will at least give me an idea on thickness and core shift.

The results seem pretty good. It picked up that the thrust and anti thrust sides of the cylinders are thicker than the sides and core shift seems reasonable but it seems to be reading thicker than reality. I'm just wondering how far off my gauge is. Does anyone have experience with measured thicknesses on a stock bore 340? Based on Chrysler's literature it should be 0.140" nominally at the middle of the water jacket between the cylinders and 0.160" at the top/bottom.

The results seem pretty good. It picked up that the thrust and anti thrust sides of the cylinders are thicker than the sides and core shift seems reasonable but it seems to be reading thicker than reality. I'm just wondering how far off my gauge is. Does anyone have experience with measured thicknesses on a stock bore 340? Based on Chrysler's literature it should be 0.140" nominally at the middle of the water jacket between the cylinders and 0.160" at the top/bottom.