Ok, so got my spring heights measured on pass side head.

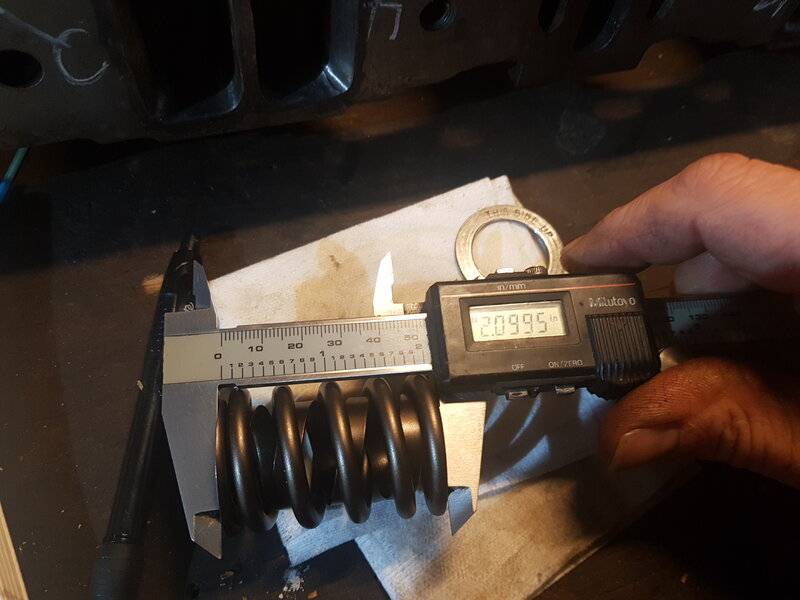

I measured(verniers and small machinists ruler) each valve in 3 different spots, and im averaging between 1.650" and 1.660".

That's with no shims and valves fully closed.

Springs are 942's

Specs 115lb/1.700" inst height

339lb/in spring rate

Coil bind 1.125"

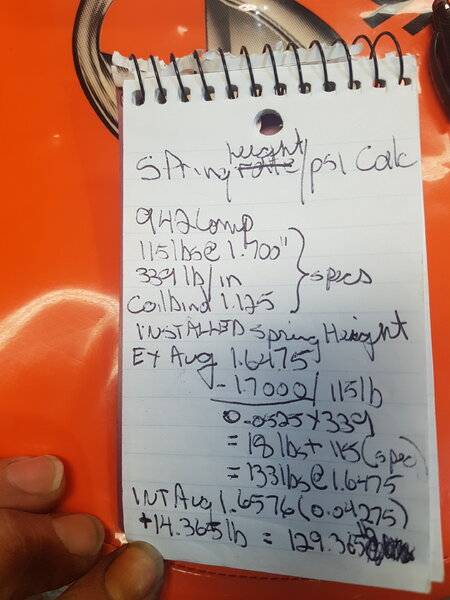

See pic where I've hand written the rest of calculations, but end result I get is

Ex [email protected]"

Int [email protected]"

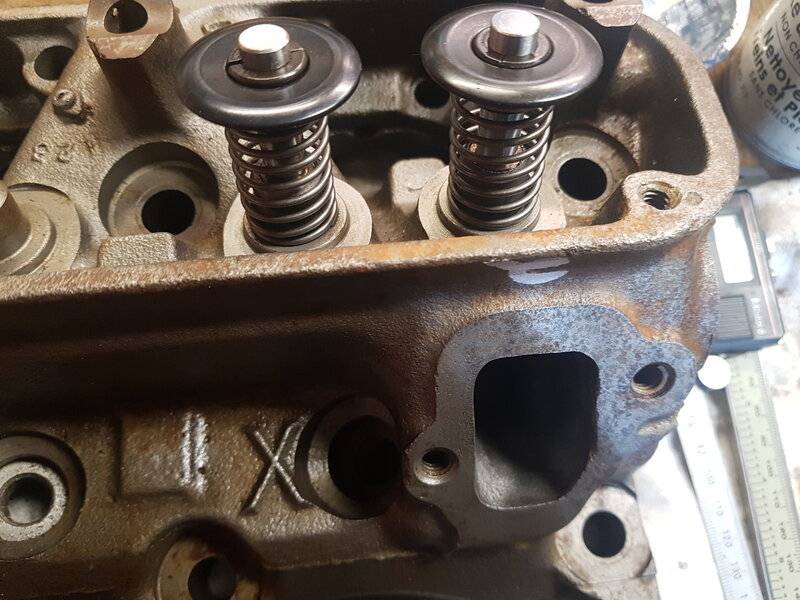

To note, when the valve job was done 30 years ago the OEM 340 springs were reinstalled with shims(see pic) 0.0585" thick.

Why would machinist(good mopar guy) shimmied them? To increase seat psi?

It couldnt have been to lower inst height as without shims I'm already around 1.65", 1.66"

Also of course shims I bought are too small ID , but in reality i dont think they need shimming?

, but in reality i dont think they need shimming?

Also the spring pocket is approx .125" deep. If I drop the prev shim in, then I'm reducing the pocket by the shims thickness(0.0585").

I placed a 942 in loose and I sure as heck wouldnt shim if i dont need to.

Input/advice?

I'm sure there will be more questions lol

Thanks

Steve

I measured(verniers and small machinists ruler) each valve in 3 different spots, and im averaging between 1.650" and 1.660".

That's with no shims and valves fully closed.

Springs are 942's

Specs 115lb/1.700" inst height

339lb/in spring rate

Coil bind 1.125"

See pic where I've hand written the rest of calculations, but end result I get is

Ex [email protected]"

Int [email protected]"

To note, when the valve job was done 30 years ago the OEM 340 springs were reinstalled with shims(see pic) 0.0585" thick.

Why would machinist(good mopar guy) shimmied them? To increase seat psi?

It couldnt have been to lower inst height as without shims I'm already around 1.65", 1.66"

Also of course shims I bought are too small ID

, but in reality i dont think they need shimming?

, but in reality i dont think they need shimming?Also the spring pocket is approx .125" deep. If I drop the prev shim in, then I'm reducing the pocket by the shims thickness(0.0585").

I placed a 942 in loose and I sure as heck wouldnt shim if i dont need to.

Input/advice?

I'm sure there will be more questions lol

Thanks

Steve