mopowers

Well-Known Member

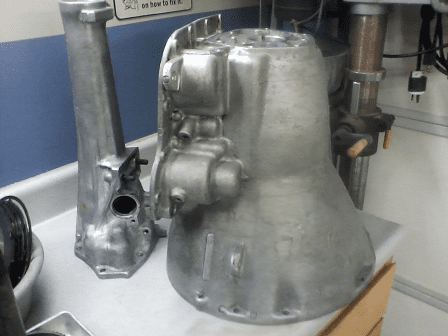

Got the case cleaned up. Boy, what a pain in the butt that was. Now I just have to wait for the parts to start coming in so I can put this ***** back together.

Can you explain in more detail here. What do you mean by pointing up and why would that affect the band adjustment?one more thing. when you adjust the bands, make sure trans pan mounting is pointing up. the reason for that is so the bands are "at rest" as opposed to being cocked down. you will get almost perfect band adjustment that way.

A high pressure valve body usually means a transbrake. You said you were going to use a manual shift, they are usually lower pressure.Thanks Kim! Just to play devil's advocate, if it's designed in, why does CRT and A&A sell thicker pistons to eliminate that play?

Do you see any issue with using the stock early style belleville spring with a high pressure valvebody?

Posted in Tom Hands torqueflite book is a pic of a smooth and a grooved clutch disc. It specifically states that smooth clutches are to be used in the rear clutch only and the parallel grooved are to be used in the front to allow oil to exit quicker in rapid clutch applications.All the 6-7 plate directs use smooths that I have seen. I thought the grooves were for cooling. But Red Eagles can take the heat. If the grooves were for hydroplaning, then they would be radial.

As the title suggests, I'm beginning to gather parts for a 727 build for my street strip 66 Dart. The engine will be a 470-512 low deck stroker (undecided on CI), but shooting for 600-650 hp. The car will run mid-10s in street trim.

So far, I'm considering a reverse manual valve body w/ LBA, bolt in sprag, billet rear servo, blocking 'load control' hole on front servo, 4.2 kickdown lever, w/ hd band strut, accumulator blocker rod, rebuild kit with new clutches, steels, and bands.

My question is, what parts would you upgrade in the 727, if any, for this type of build, or any other modifications would you make? I realize a stock 727 may work fine for some time, but I'd like to build it once and know it'll last with no issues.

Thanks!

i here ya. You could go with the theory that the smooth ones would give you more surface area too.Sorta like a rain tire I guess. But I don't buy it. TH400s have all smooth clutches. The reds are available in thick smooth for the direct clutch. I'll go with Alto's ideas on recommendations.

Not quite true. They were available in smooth, radial lined, and waffle patterns. Trucks and heavy duty applications typically had either the radial lined or waffle in the forward, direct and intermediate clutch packs. Higher end cars like Cadillac and the like used only smooth plates to the best of my knowledge. Again, just my experience.Sorta like a rain tire I guess. But I don't buy it. TH400s have all smooth clutches. The reds are available in thick smooth for the direct clutch. I'll go with Alto's ideas on recommendations.

Sounds like this comes down to a shift quality issue. Smooth clutches offering perhaps a smoother less aggressive apply.Not quite true. They were available in smooth, radial lined, and waffle patterns. Trucks and heavy duty applications typically had either the radial lined or waffle in the forward, direct and intermediate clutch packs. Higher end cars like Cadillac and the like used only smooth plates to the best of my knowledge. Again, just my experience.

A couple of good performance builders I know, will also use the HI ENGERGY friction plates as used in the 518 and 618 series of transmissions. A lot depends on how hard you're going to beat on the thing and to a point the builders experience. In your situation though, I'd go with the performance with the ALTO'S.

Perhaps that is why I see a common recommendation of 4 smooth clutches in the rear drum and 5 grooved clutches in the front, to get the same surface area but with more aggressive shift qualities from 2-3 gear change.I measured the width of the grooves and multiplied by the total length. A grooved plate has 20% less surface contact area. A four plate smooth has the same contact area of a five plate grooved.

I was referring to the issue of clutch counts.The reason that grooved clutches are used in 2nd and 3rd gear applications is because the oem and most aftermarket clutch material is inferior to Alto's Red Eagle material. They need grooves to dissipate heat. The forward clutch is applied at idle and remains applied thru all shifts. Not a shift quality issue; shift quality is easily varied with changes in pressure. I have heated various clutch and band materials and have found that the Red Eagle is superior to all except kevlar.

What size rear tires and rear axle ratio are you planning on?As the title suggests, I'm beginning to gather parts for a 727 build for my street strip 66 Dart. The engine will be a 470-512 low deck stroker (undecided on CI), but shooting for 600-650 hp. The car will run mid-10s in street trim.

So far, I'm considering a reverse manual valve body w/ LBA, bolt in sprag, billet rear servo, blocking 'load control' hole on front servo, 4.2 kickdown lever, w/ hd band strut, accumulator blocker rod, rebuild kit with new clutches, steels, and bands.

My question is, what parts would you upgrade in the 727, if any, for this type of build, or any other modifications would you make? I realize a stock 727 may work fine for some time, but I'd like to build it once and know it'll last with no issues.

Thanks!

A high pressure valve body usually means a transbrake. You said you were going to use a manual shift, they are usually lower pressure.

What size rear tires and rear axle ratio are you planning on?

That may have an influence on your trans build as far as ideal gear ratios.

My thoughts were on your first gear ratio with that big of a motor.The valvbody I'm getting is set at 155 psi. Is that considered low pressure? Low enough to not worry about a thinner rear clutch piston?

Rear gears are 4.10s w/ a 30" radial tire. Any thoughts on how that would influence the list of necessary transmission parts?

I would say that pressure is in between. Why not buy the taller piston and fix the issue, then if you decide later to add a brake or turn the pressure up more, you won't have to take the trans apart.The valvbody I'm getting is set at 155 psi. Is that considered low pressure? Low enough to not worry about a thinner rear clutch piston?

Rear gears are 4.10s w/ a 30" radial tire. Any thoughts on how that would influence the list of necessary transmission parts?

Fair enough.The third gear clutch is applied under high rpm and greater pressures than the forward clutch. The forward clutch is applied at idle, whereas the direct clutch is applied commonly in a racing application at 8k rpm and greater. The two clutches are called upon to deliver totally different performances. Fact is, the most common repair in a TF is replacement of the direct clutch. I'm not on here to post what somebody else has already recommended. I post what I recommend based upon my own experiences and conclusions. I don't care what somebody's book says; I've NEVER read a book about transmissions. Just because Alto makes a grooved clutch doesn't mean that they recommend it. They are in business to sell clutches; and many builders believe a grooved clutch is necessary in the direct pack; because that's what it came with. So they manufacture a grooved clutch so they won't miss out on sales; period. The oem direct clutch is grooved because the materials used by Chrysler are inferior. If my supplier sends me grooved Altos; I send them back; it's just a waste of time, money, effort, and available space. If I put together a seven plate direct pack, it's more than TWICE as strong as a grooved four pack clutch.

I ran my last 904 build like that too. I never said it doesn't work.

What were the clutch counts on those?I have torn many 727s apart. Some indeed come without the grooves clutches in the direct drum. Kim