I spotted this first whoops in my parts cleaner. Someone got overly aggressive on an exhaust port and ground through a header bolt hole. Then on my porting bench I noticed one of the two pushrod holes was leaking. Instead of running the tube just shy of the deck surface they stopped about 3/8 of an inch short. Had to drill that brass tube out and will replace it with a longer piece. Not fun drilling that out by hand when they ground to the tube the length of it. I hate to see what I find when I pick up a grinder and clean up the port and can actually see.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A couple reasons why I hate doing port work after others

- Thread starter pittsburghracer

- Start date

-

Trying to correct someones screw up usually takes twice to three times longer, rather than them bringing it to me first. I try to be fair with fellow enthusiasts, but sometimes they really try my patience and I've lost a few due to labor costs.

Blind man (Stevie Wonder), Supervisor (Ray Charles). LMAO!!!

PRH

Well-Known Member

I’m not sure how it got there on the heads you’re working on, but I’ve seen Edelbrock SBM heads that have the exhaust bolt hole broken thru into the exhaust port right ootb.

I’m not sure how it got there on the heads you’re working on, but I’ve seen Edelbrock SBM heads that have the exhaust bolt hole broken thru into the exhaust port right ootb.

I don’t think I’ve ever ran into that yet out of the box. All I can add is we all screw up. I felt like crap earlier this year when a customer found one of my pushrod tubes leaking. He quickly fixed it but it still bothers me. I have made a couple changes since so hopefully it never happens again.

Deltatech

Well-Known Member

Probably served it's purpose and lasted long enough for the few passes they needed it for. Hey it's better than the old school grind till you break through then JB weld mess.

Goodness.

I am Done working on other people's stuff!!Trying to correct someones screw up usually takes twice to three times longer, rather than them bringing it to me first. I try to be fair with fellow enthusiasts, but sometimes they really try my patience and I've lost a few due to labor costs.

If they bring it to my shop, I will fix it for free if I can do

it in less than an hour for no charge given they leave

it for a few days until I can find the time.

Beyond that, I will give them my opinion, but I will not

put my hands on it! If they argue with me about my

advise (common) that will be the last time they receive

any from me.

At 75 year old, I have come to the realization that I have more

money than I have time at this point. I have lost patience with

time wasters and folks that grind me to death on the price of something!

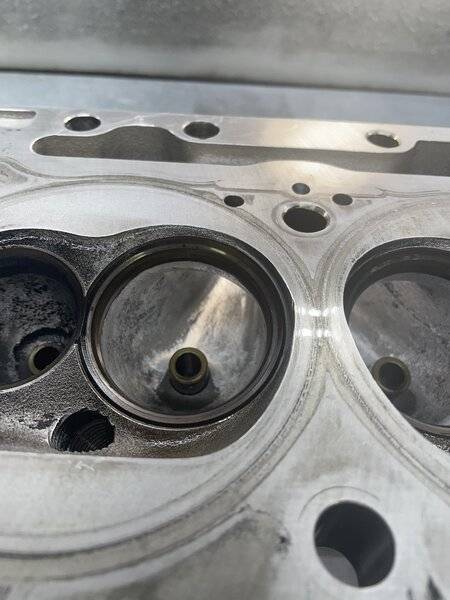

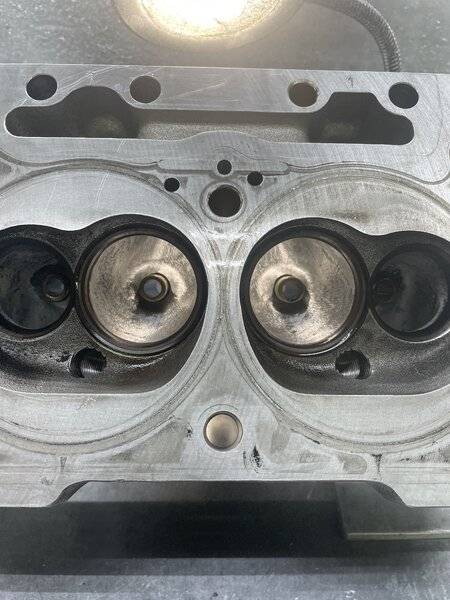

These are for a friend that has done me a lot of favors and treats my son like his son. I took my valve spring compressor to the Halloween Classic and pulled an intake and exhaust valve so I could at least see if he butchered the short turn. They were given a buff and shine so here were are. He was lead to believe they had 2.055 valves which they don’t. I’ll post up flow numbers later. They did have a very nice 4-5 angle valve job. I’m not sure what is going on with the valve seals. On the one head I stripped so far two different size valve seals were used and two didn’t have seals at all. He gets a deal on Manley valves so that’s what we will be working with. Exhaust valve are shot too so those will be getting upgraded.

This will quickly be addressed. If you see this much black carbon on a strip only car running alcohol you know you have a slow exhaust port. Had to be a lot of reversion

Deltatech

Well-Known Member

You know the short turn is butchered and the cross section is all over the place. the valve seals were probably replaced at the track to make the last run on those heads at the end of the season.

You know the short turn is butchered and the cross section is all over the place. the valve seals were probably replaced at the track to make the last run on those heads at the end of the season.

As I said the short side was nicely polished and that was about it. He did the common gotta open “the pinch” and got very aggressive there. Common wall into the valve cover holes and way to much taken out of the gasket sealing common wall. There’s no reason in hell to thin that out that much. Someone read to many books or watched to many YouTube videos.

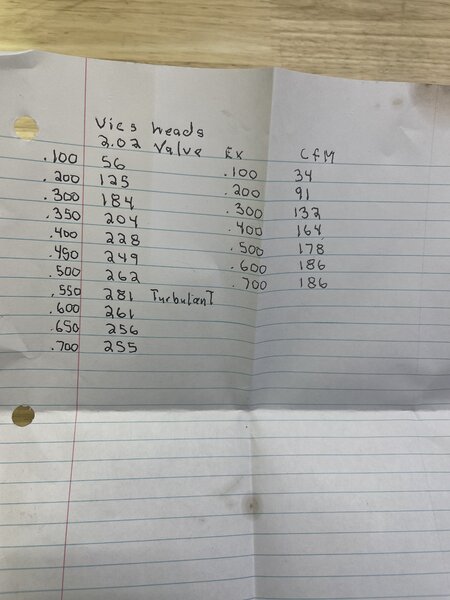

Some before flow numbers.

Well 6 hours work and I have one head 90% done. I rarely work that aggressively but I gotta get moving around here.

Deltatech

Well-Known Member

I missed your post that said the short Turn was nicely polished unless that's what you ment by "buff and shine".

500HP potential isn't aweful albeight I've seen those often flow over 300cfm with good porting in the right areas.

Are you going to be honest and tell him those heads have been ruined?

This was written before your post above showing that you saved the heads.

500HP potential isn't aweful albeight I've seen those often flow over 300cfm with good porting in the right areas.

Are you going to be honest and tell him those heads have been ruined?

This was written before your post above showing that you saved the heads.

Last edited:

I missed your post that said the short Turn was nicely polished unless that's what you ment by "buff and shine".

500HP potential isn't aweful albeight I've seen those often flow over 300cfm with good porting in the right areas.

Are you going to be honest and tell him those heads have been ruined?

What the hell are you talking about buddy.

........And I add "If it breaks again don't bring it back. It doesn't have a warranty".I am Done working on other people's stuff!!

If they bring it to my shop, I will fix it for free if I can do

it in less than an hour for no charge given they leave

it for a few days until I can find the time.

Beyond that, I will give them my opinion, but I will not

put my hands on it! If they argue with me about my

advise (common) that will be the last time they receive

any from me.

At 75 year old, I have come to the realization that I have more

money than I have time at this point. I have lost patience with

time wasters and folks that grind me to death on the price of something!

Humans are complicated creatures (SOME) !I am Done working on other people's stuff!!

If they bring it to my shop, I will fix it for free if I can do

it in less than an hour for no charge given they leave

it for a few days until I can find the time.

Beyond that, I will give them my opinion, but I will not

put my hands on it! If they argue with me about my

advise (common) that will be the last time they receive

any from me.

At 75 year old, I have come to the realization that I have more

money than I have time at this point. I have lost patience with

time wasters and folks that grind me to death on the price of something!

Any guesses on what a set of my heads with a 2.08 valve are gonna flow.

290 to 300 @ 600 lift?

Just a wild guess!

Just a wild guess!

Last edited:

307 somewhere between .500-.700Any guesses on what a set of my heads with a 2.08 valve are gonna flow.

310+Any guesses on what a set of my heads with a 2.08 valve are gonna flow.

junkyardhero

Well-Known Member

tail light warranty with a two part guarantee!........And I add "If it breaks again don't bring it back. It doesn't have a warranty".

warranty is over as soon as i see your tail lights, and if it breaks in two you get to keep both parts!

-