And double checking myself. I boxed theses heads and intake up so I could get a shipping quote as the customer is sending me a check. So I unpacked everything to give them a valve job and flow testing. Well I set up the new 4 angle seat cutter I bought. Then I mounted the head on my seat machine and when I dry ran everything before cutting the seat the cutter was hitting the deck of the head. Now all I do to these Speedmaster heads is radius the edge left from the cutter they use on the intake valve and blend it in. I don’t even blue these heads anymore because the speedmaster heads give me better low lift numbers out of the box than the Edelbrock heads do easily hitting my [email protected]. Well someone dropped the ball on this set. I dug out a stock set of mine and measured the divider between the two intake valves and it measured.430. My heads were dated 2023-03-02-0088.

His both measured .513-.515 but remember I blended this some. His were dated 2022-09-17-0101.

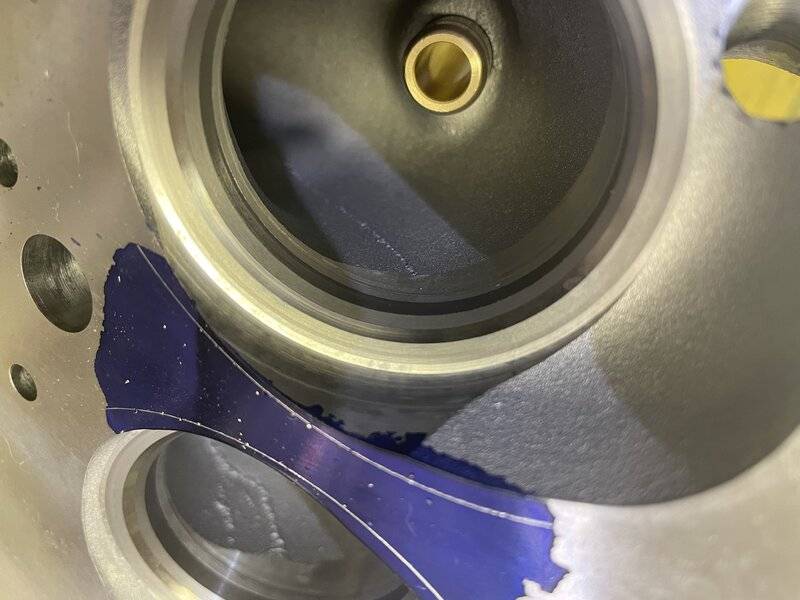

Here’s a few pictures. With my old Neway cutters it wouldn’t have been caught or possibly mattered but with a 4 angle cutter on a seat machine it’s not possible.

His both measured .513-.515 but remember I blended this some. His were dated 2022-09-17-0101.

Here’s a few pictures. With my old Neway cutters it wouldn’t have been caught or possibly mattered but with a 4 angle cutter on a seat machine it’s not possible.