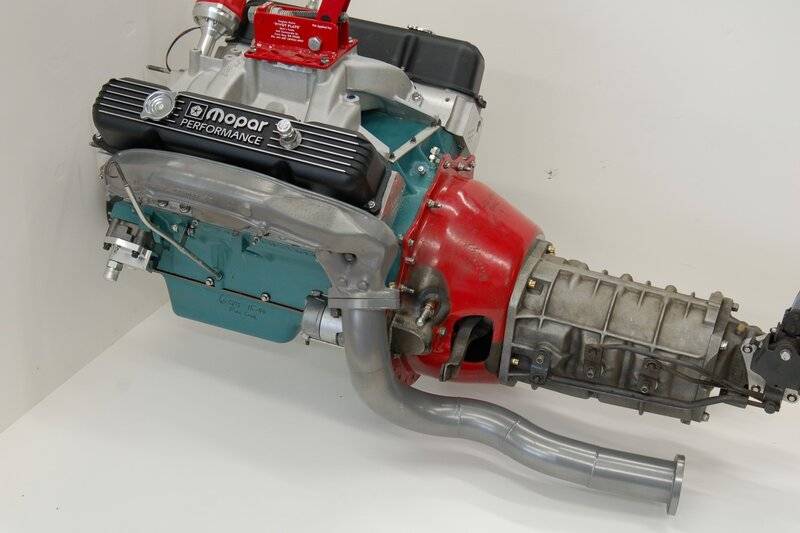

Here is a mockup I did for a buddy who wanted to run a Doug Nash behind his small block. QT makes a bellhousing for that application which is cool, but there wasn't a support for the starter nose. After thinking about it for a while my buddy decided not to use the QT bellhousing since he was concerned about starter support. We thought about fabricating a nose support but decided to go a different way.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bellhousing Experience Quicktime vs Lakewood

- Thread starter desmo900

- Start date

-

The Lakewood in my Coronet had to be heavily modified to work. The starter nose had to be shortened for linkage clearance. The bellhousing had to be blanchard ground on both sides since it wasn't flat or parallel and the pivot point had to be raised to work correctly.

1WildRT

Well-Known Member

I worked on a car with a Quick Time Bell... The alignment was off by over .065.. Nobody sells offset dowels to correct that much misalignment.... So I machined a pair.... Only to discover that in order to bolt the bellhousing to the block I would have to open up the bolt holes... Customer didn't want to do that so it got sent back to QT... Used a stock bellhousing that bolted up and was within .003 with standard dowels..

mopardude318

Well-Known Member

I’ll be using a hydraulic clutch, I got my QuickTime pretty close, if I did it right. Lol.

I didn’t think about the no support for the starter nose. I’ll find out I guess.

I didn’t think about the no support for the starter nose. I’ll find out I guess.

Going to run a QuickTime bell. Big block to TKX. I have only bolted trans to block. And bolted assembly into car. For prepping car for TKX. Hopefully my run out is not way out? I wonder how many aftermarket starters are designed to be used without the snout support? Quick time bells and modern transmissions are quite popular now among all makes. Hopefully not a issue?

-