plumkrazee70

Well-Known Member

So I have the new block and rotating assembly at the machine shop now. He is going to look at everything next week, and unless something isn't usable, we will be moving forward with my rotating assembly. I am heavily considering changing cams because the Lunati 703 didn't produce very much vacuum (10-11") and for the EFI, I'd really like it to be higher.

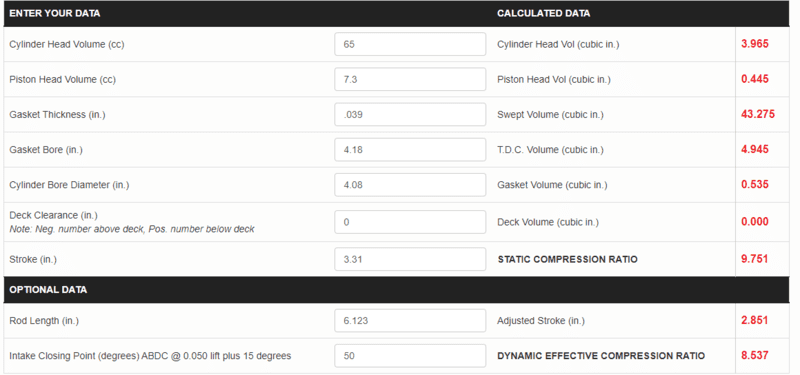

So I reached out to Hughes and I was surprised at his response. (see below) Keep in mind I used a calculator for the compression calculation. (attached). I didn't realize that altitude decreased vacuum.

You have some things working against you. Aluminum heads only 9.3:1 compression. Aluminum heads should be about 1. Above what you would run with iron head and your 1300’ altitude works against you too. Both of them will lower the vacuum even more. I suggest our SER1822ALN Ca, 5006 lifters, and 1199 spring kit or you could go with the next size larger cam SER2226AL and use the 5007 lifters which “bleed down” at idle and lower RPM, giving you more vacuum and more mid-range power.

I am going to have the machinist measure my actual compression, to be sure but, my question is how do I increase the compression so that factor isn't working against me?

Here is what the calculator looks like with the first cam he recommended.

69 340 block

KB 243 (assuming .018 out the hole, just like the old 68 block)

Eddy aluminum 65cc heads (pn 60179 for the piston clearance)

Air Gap

EFI

So I reached out to Hughes and I was surprised at his response. (see below) Keep in mind I used a calculator for the compression calculation. (attached). I didn't realize that altitude decreased vacuum.

You have some things working against you. Aluminum heads only 9.3:1 compression. Aluminum heads should be about 1. Above what you would run with iron head and your 1300’ altitude works against you too. Both of them will lower the vacuum even more. I suggest our SER1822ALN Ca, 5006 lifters, and 1199 spring kit or you could go with the next size larger cam SER2226AL and use the 5007 lifters which “bleed down” at idle and lower RPM, giving you more vacuum and more mid-range power.

I am going to have the machinist measure my actual compression, to be sure but, my question is how do I increase the compression so that factor isn't working against me?

Here is what the calculator looks like with the first cam he recommended.

69 340 block

KB 243 (assuming .018 out the hole, just like the old 68 block)

Eddy aluminum 65cc heads (pn 60179 for the piston clearance)

Air Gap

EFI