plumkrazee70

Well-Known Member

Hey Everyone.

I am moving forward with a set of edelbrock aluminum heads for my 340. Since I am going to be in there, I am going to have my hydraulic cam reground.

Ken suggested a custom grind with the following info:

224/[email protected]

480 lift

112 Lobe (due to EFI)

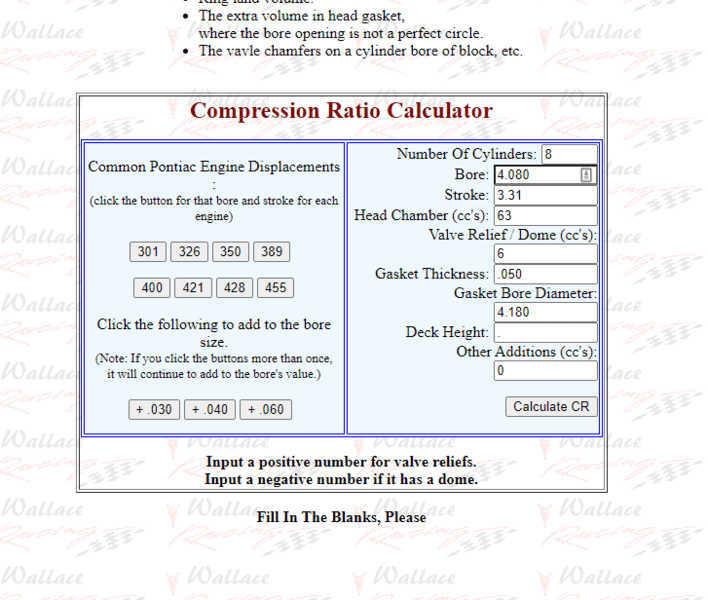

He did say determining compression ratio will help him make a better choice, so I plugged my numbers(screen shot attached) into the wallace calculator and got 9.84. I wasn't sure what to put the deck height at (is this how far the piston sits in or out of the hole)?

I just wanted to be sure that the numbers I plugged in looked correct. I got the headgasket thickness and the bore diameter from the edelbrock listing on Summit.

I am moving forward with a set of edelbrock aluminum heads for my 340. Since I am going to be in there, I am going to have my hydraulic cam reground.

Ken suggested a custom grind with the following info:

224/[email protected]

480 lift

112 Lobe (due to EFI)

He did say determining compression ratio will help him make a better choice, so I plugged my numbers(screen shot attached) into the wallace calculator and got 9.84. I wasn't sure what to put the deck height at (is this how far the piston sits in or out of the hole)?

I just wanted to be sure that the numbers I plugged in looked correct. I got the headgasket thickness and the bore diameter from the edelbrock listing on Summit.