You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Console Shifter movement

- Thread starter body

- Start date

-

I take it that the shifter was out.

Here's what I did:

Here's what I did:

- drop the linkages from underneath the car with all positions in neutral

- put someone in the drivers seat to hold the shifter in neutral

- un-screw or scew in each linkage rod until it reaches the transmission shifting "dogs", without tugging on the rods

- secure each nut to the shifting dog as you go

rustycowll69

Well-Known Member

in the early a-body 4spds, for Hurst shifters, I always used the (1/4"?) pin method for the forward gears, but adjusted the reverse lever all on its own, irrespective of the pin.

I made the top out of an automatic. The shifter boot fits inside snug and i just glued it on . The problem is as you can see the shifter is pretty close to the edge when shifted in reverse and then with the boot not egnough movement . Others have made there own tops . Should the boot fit tight inside?

Maybe the boot should be down lower in the hole ? Like with bosses on the 4 speed top ?I made the top out of an automatic. The shifter boot fits inside snug and i just glued it on . The problem is as you can see the shifter is pretty close to the edge when shifted in reverse and then with the boot not egnough movement . Others have made there own tops . Should the boot fit tight inside?

It has the appearance of a "A" body console shifter....but is the Inland? It's a complicated set of bends to get it to work right.

How do you end in in this situation?

Did you add a console to a car without one?

Did you change the shifter out?

Did you make a 4 speed out of an automatic?

It must have worked at one time

How do you end in in this situation?

Did you add a console to a car without one?

Did you change the shifter out?

Did you make a 4 speed out of an automatic?

It must have worked at one time

It has the appearance of a "A" body console shifter....but is the Inland? It's a complicated set of bends to get it to work right.

How do you end in in this situation?

Did you add a console to a car without one?

Did you change the shifter out?

Did you make a 4 speed out of an automatic?

It must have worked at one time

Obviously 2nd, 4th and reverse share the same "back " position. Assuming the position for the shifter hole the is in a workable spot... with the linkage rods off the tranny, you might engage reverse with an adjustable wrench and find a rod adjustment setting where the "back" shifter position is reachable with the reverse rod. Then try one of the forward gears (1st or 3rd) and adjust the rod accordingly...

There's got to be an adjustment that fits.

I hope this helps

There's got to be an adjustment that fits.

I hope this helps

Thanks. I thought you can only do the adjustment in neutral with the pin in the hurst shifter?Obviously 2nd, 4th and reverse share the same "back " position. Assuming the position for the shifter hole the is in a workable spot... with the linkage rods off the tranny, you might engage reverse with an adjustable wrench and find a rod adjustment setting where the "back" shifter position is reachable with the reverse rod. Then try one of the forward gears (1st or 3rd) and adjust the rod accordingly...

There's got to be an adjustment that fits.

I hope this helps

Will that be ok on a 67 cast iron transmission? Kinda new to the 4 speedsin the early a-body 4spds, for Hurst shifters, I always used the (1/4"?) pin method for the forward gears, but adjusted the reverse lever all on its own, irrespective of the pin.

rustycowll69

Well-Known Member

yes, I believe soWill that be ok on a 67 cast iron transmission? Kinda new to the 4 speeds

rustycowll69

Well-Known Member

you are aware of the 1/4"dia.(I think) hole/notch in the shifter body and shifter body arms to line up the shifter in neutral, I assume?

Use the pin to adjust the forward gear rods to the correct length. Although the shifter body reverse lever has a pin hole, it always worked better for me to ignore the pin for the reverse lever and just adjust the reverse rod separately, so the shifter engages reverse properly.

Use the pin to adjust the forward gear rods to the correct length. Although the shifter body reverse lever has a pin hole, it always worked better for me to ignore the pin for the reverse lever and just adjust the reverse rod separately, so the shifter engages reverse properly.

I think I figured it out . I bought the transmission from someone on Craigslist. Turns out it has a 64 shifter mount on it or the same one as a Hurst super shifter . Won't work right no matter what you do with a console. Thanks .

694spd

Well-Known Member

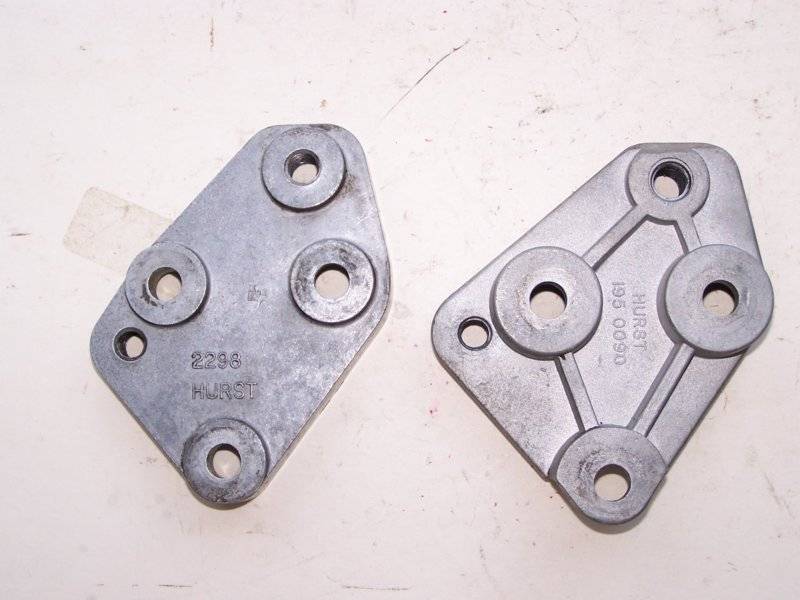

Yes, the 2298 shifter mounting plate which was used on the 64-65 Hurst shifter in A-bodies and it also came with the aftermarket Hurst Competition Plus shifter install kits.

It tilts the shifter the the slightly to the rear when compared to the factory shifter plate.

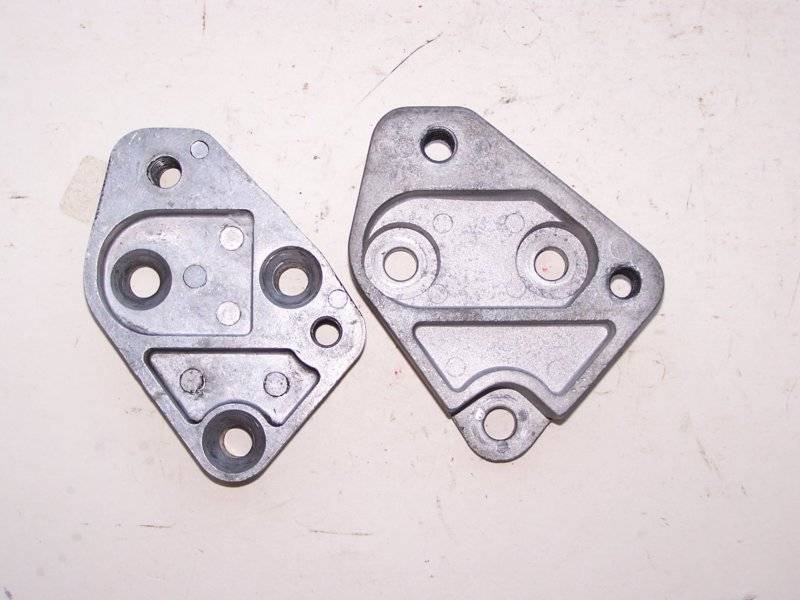

In the picture below. The plate on the left is the 2298 one. The one on the right is the

195 0090 plate that was used with the factory installed Hurst shifter starting in mid 1968 and later.

It tilts the shifter the the slightly to the rear when compared to the factory shifter plate.

In the picture below. The plate on the left is the 2298 one. The one on the right is the

195 0090 plate that was used with the factory installed Hurst shifter starting in mid 1968 and later.

694spd

Well-Known Member

Here is a couple of pictures showing the factory 1969 Hurst shifter and rods compared to a Hurst Competition shifter and rods installed on the same transmission. You can see that the competition plus shifter is mounted more up right.

I currently using that the comp. plus shifter in my Dart with a 1971 and later factory bolt in handle.

I currently using that the comp. plus shifter in my Dart with a 1971 and later factory bolt in handle.

Thanks! Yeah I was stumped until I looked at some pictures of the mount plate . The mount had spacers on it too . That's why when I shifted to the reverse gate it would budge up against the console edge. So I ordered the 67 one and new linkage rods.

-