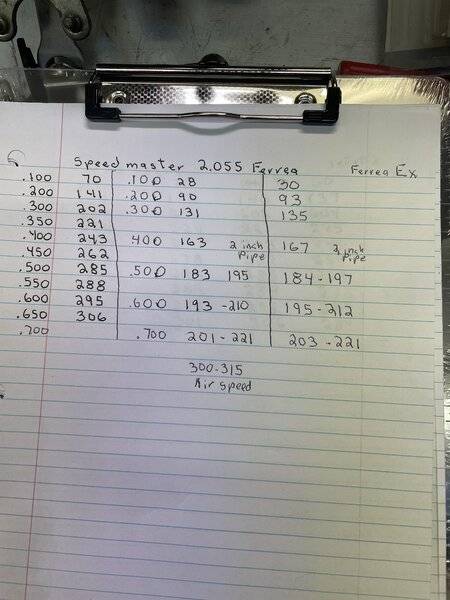

A few of you guys sounded interested and I was curious so I flowed the exhaust on a ported exhaust port first with a Speedmaster valve then a Ferrea exhaust valve the customer wanted. After opening up the packaging on the Ferrea valve and compared it to the Speedmaster I got exactly what I expected, not much. Both valves are untouched. I should have started a new page as this is a little confusing. I check exhausts at every .100 not .050 because I’m most interested in airspeed and aim for 325fps in the port. I found 300-315 as I kinda expected because he didn’t want to lose compression so the chamber is totally untouched except for minor spark plug hole layback. Ok the Speedmaster valve is center page and the number at .500, .600, .700 is with a two inch pipe held up to the port exit. The far right two columns are the Ferrea exhaust valve. Not much difference but he wanted the security of a better valve.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ferrea to Speedmaster exhaust valve test

- Thread starter pittsburghracer

- Start date

-

Wow, interesting. Not enough difference to worry about as far as design. The Ferrea valves may be higher quality I would imagine.

Locomotion

Well-Known Member

Interesting & valuable information, especially for rule restricted classes, like Stock and Super Stock and some circle track engines which require OEM sized valves. Horsepower can get hard to find and the little cc gains in flow can add up to noticeable performances gains especially when combined with other improvements, regardless of how small. I forgot the details, but I believed I read somewhere that 2cc in flow is roughly worth about 1 HP.

It's kind of like wanting to lighten a car by 100 lbs. It may not be possible to find a 100 lb part to remove, \but finding 100 places to remove 1 lb is usually easier. Attention to detail and little things add up.

It's kind of like wanting to lighten a car by 100 lbs. It may not be possible to find a 100 lb part to remove, \but finding 100 places to remove 1 lb is usually easier. Attention to detail and little things add up.

Nice pickup with just a valve change, plus a good benefit having a quality valve that is less likely to fail. The jury is still out on the Speedmaster products, haven't seen anyone put them to the test on high output engines yet.

MidnightSwinger

Well-Known Member

I think that is a worthwhile upgrade. I opted for bare speedmaster heads. I think the money I saved buying the heads is destined to go towards good valves/springs/keepers and a valve job.

Who here knows definitively? Who has done metallurgical analysis of either brand? And, is it a proven fact that Ferrea actually manufactures and machines their valves? Where’s the stainless sourced from? Lots of companies (in general) import and machine (or finish) as we all know.The Ferrea valves may be higher quality I would imagine.

Maybe Ferrea does it all, or maybe just machines a nice finished imported valve?

Oh I agree.Who here knows definitively? Who has done metallurgical analysis of either brand? And, is it a proven fact that Ferrea actually manufactures and machines their valves? Where’s the stainless sourced from? Lots of companies (in general) import and machine (or finish) as we all know.

Maybe Ferrea does it all, or maybe just machines a nice finished imported valve?

MidnightSwinger

Well-Known Member

I don’t disagree. I do have more faith in Ferrea as a company,to stand behind their product in the event of a failure. They also have years of R&D in Racing and performance, whereas SM is just ripping Edelbrock off.Who here knows definitively? Who has done metallurgical analysis of either brand? And, is it a proven fact that Ferrea actually manufactures and machines their valves? Where’s the stainless sourced from? Lots of companies (in general) import and machine (or finish) as we all know.

Maybe Ferrea does it all, or maybe just machines a nice finished imported valve?

How much does each valve weigh?

Speedmaster

3.3 Oz. Or 93 grams

Ferrea

3.5 Oz. Or 99 grams.

Locomotion

Well-Known Member

I'm curious if the weight difference is from a difference in the valve head/chamber side of the valves and/or a different shape/slope on the port side.Speedmaster

3.3 Oz. Or 93 grams

Ferrea

3.5 Oz. Or 99 grams.

Over the years I've read that Mopar wedge engines tend to prefer flatter/nail-head intakes and more "tulip" shaped exhaust valves. But I'm sure that there might be other variables, not just an across-the-board standard.

Valve that are undercut in the stem for flow would be interesting to test also and would be saving weight too.

-