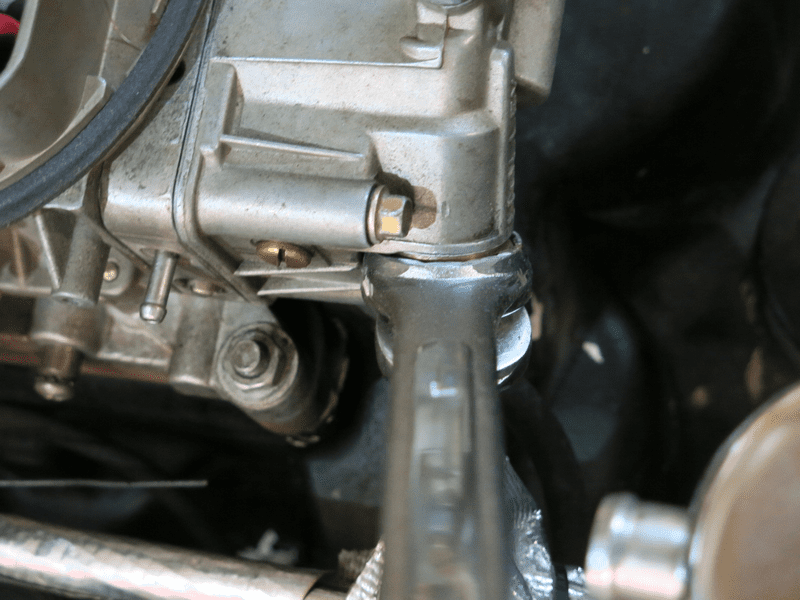

Years ago I saw a fuel bowl inlet wrench in a catalog that was a stamping. I wish I bought it. Never seen one since. One of the most annoying things with the stock inlets on 4150/60 carbs is having the inverted flare adapter move when removing the inverted flare nuts on the fuel lines. Yet its always awkward to get an open end wrench in place with good bite.

Finally modified a 1" box wrench that I bought for this purpose at a fleamarket last year.

Works pretty good.

May do more filing in the future as needed.

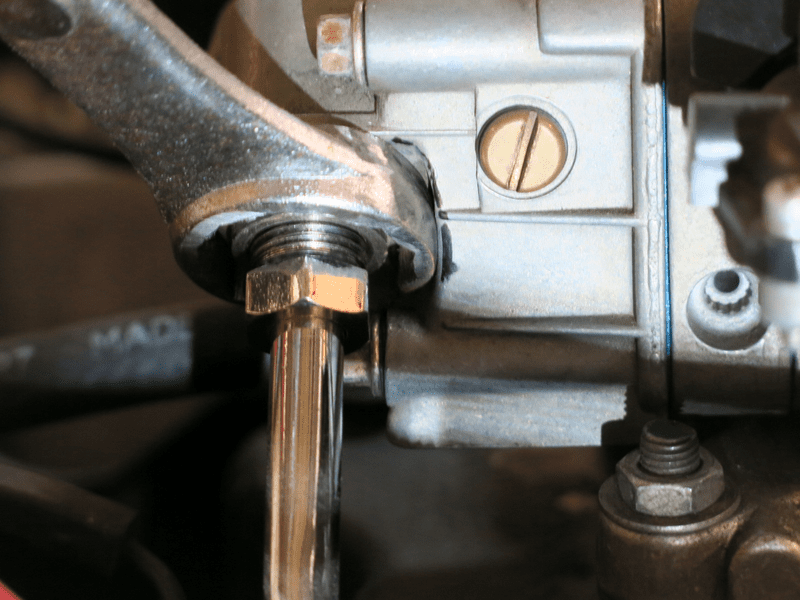

Finally modified a 1" box wrench that I bought for this purpose at a fleamarket last year.

Works pretty good.

May do more filing in the future as needed.