67bluefish

Active Member

I recently picked up a PST polygraphite front suspension kit for my '67 fastback, and have been slowly going about replacing the various bushings, etc., that haven't been touched in 40+ years.... (I asked about some tie rod end removal info a week or so ago - thanks for the help!)

So, here are the problems:

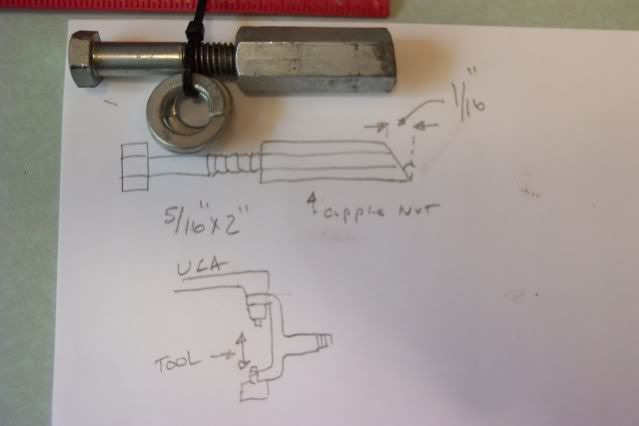

1: Upper control arm cam bolt removal! Managed to get the front, driver's side cam bolt out, after releasing several years worth of frustration with a BFH. Managed to get the cam washer off the rear driver's side bolt, but the bolt itself won't budge. :banghead: I've been reading about Kroil, and am planning to pick some up tomorrow; I want to stay away from cutting or heat if I can.... any other suggestions?

2: Steering knuckle removal - I've got one bolt holding the driver's side (DS) steering knuckle on (bottom right, when looking in from the outside) that won't budge. Have also applied liberal amounts of BFH, to no avail. :banghead: Thoughts?

3: Lower ball joint removal: I've got the castellated nut released, but this is the same steering knuckle as described above, so of course it is being as difficult as possible. :mumum: Someone mentioned that having the steering linkage connected might help, as it will give me something solid to bang against. I'm open to that, just wondering if there are any other suggestions out there.

Thanks for the help, folks! This is one of the few times this year that I'll be able to work on the car (living in a different state) so I'm trying to get as much done this week as I can.

So, here are the problems:

1: Upper control arm cam bolt removal! Managed to get the front, driver's side cam bolt out, after releasing several years worth of frustration with a BFH. Managed to get the cam washer off the rear driver's side bolt, but the bolt itself won't budge. :banghead: I've been reading about Kroil, and am planning to pick some up tomorrow; I want to stay away from cutting or heat if I can.... any other suggestions?

2: Steering knuckle removal - I've got one bolt holding the driver's side (DS) steering knuckle on (bottom right, when looking in from the outside) that won't budge. Have also applied liberal amounts of BFH, to no avail. :banghead: Thoughts?

3: Lower ball joint removal: I've got the castellated nut released, but this is the same steering knuckle as described above, so of course it is being as difficult as possible. :mumum: Someone mentioned that having the steering linkage connected might help, as it will give me something solid to bang against. I'm open to that, just wondering if there are any other suggestions out there.

Thanks for the help, folks! This is one of the few times this year that I'll be able to work on the car (living in a different state) so I'm trying to get as much done this week as I can.