rich006

Learning as I go

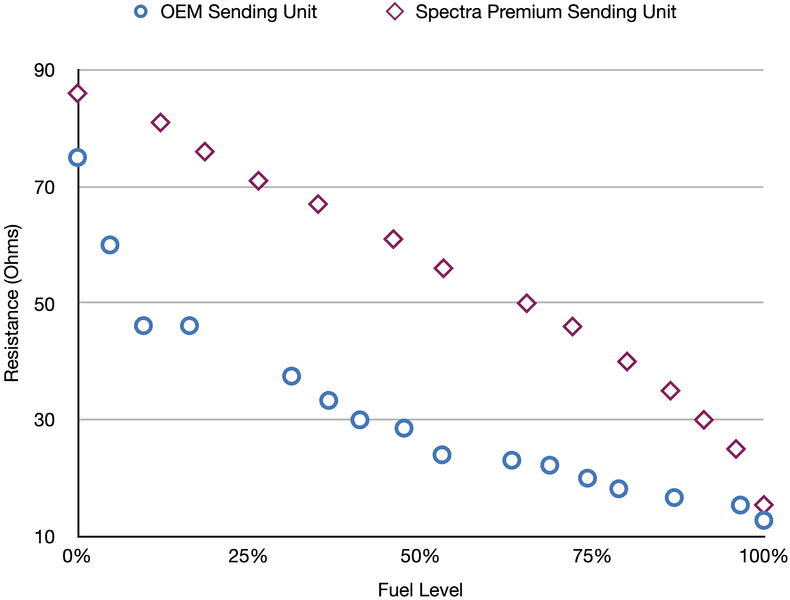

I posted this on slantsix.org but I thought I should share it here too. There have been several threads here about the aftermarket sending units not working quite right with the factory gauge. In particular, it reads full when full, empty when empty, but at mid-ranges the aftermarket unit reads much lower than it should. In other words, when you have 3/4 tank, your gauge reads 1/4. These aftermarket units are made by Spectra Premium. I called them to complain about it, and surprisingly a person answered the phone. He told me it's designed to put out 80 ohms empty and 10 ohms full, same as the factory sending unit. I explained it's the mid-range where it's off, and he said he'd report that to the tech team.

I compared the response of the OEM sending unit to that of the Spectra Premium. First I measured the resistance of each at several float angles. Then I did a little geometry and math to convert float angle to fuel level. Here are the results. As you can see, the Spectra unit matches the factory unit reasonably well at the end points (as the Spectra rep told me), but in the mid-range its resistance is much too high, leading to a too-low gauge reading. For more details on my measurement process, read below the picture.

Geometry: I measured the float angle relative to horizontal. I reasoned that the float height (fuel level) is proportional to the sine of the float angle, plus a constant.

Electrical measurements: On the OEM unit I couldn't get steady resistance measurements, so I hooked it up to a 6V flashlight battery and measured the current. From there I used R=V/i to get the resistance. Those current measurements were steady, but my multimeter only reads to the nearest 10 mA of current, so the higher-resistance measurements are a bit uncertain. On the Spectra unit I read the ohms directly with the multimeter.

I compared the response of the OEM sending unit to that of the Spectra Premium. First I measured the resistance of each at several float angles. Then I did a little geometry and math to convert float angle to fuel level. Here are the results. As you can see, the Spectra unit matches the factory unit reasonably well at the end points (as the Spectra rep told me), but in the mid-range its resistance is much too high, leading to a too-low gauge reading. For more details on my measurement process, read below the picture.

Geometry: I measured the float angle relative to horizontal. I reasoned that the float height (fuel level) is proportional to the sine of the float angle, plus a constant.

Electrical measurements: On the OEM unit I couldn't get steady resistance measurements, so I hooked it up to a 6V flashlight battery and measured the current. From there I used R=V/i to get the resistance. Those current measurements were steady, but my multimeter only reads to the nearest 10 mA of current, so the higher-resistance measurements are a bit uncertain. On the Spectra unit I read the ohms directly with the multimeter.

.

.