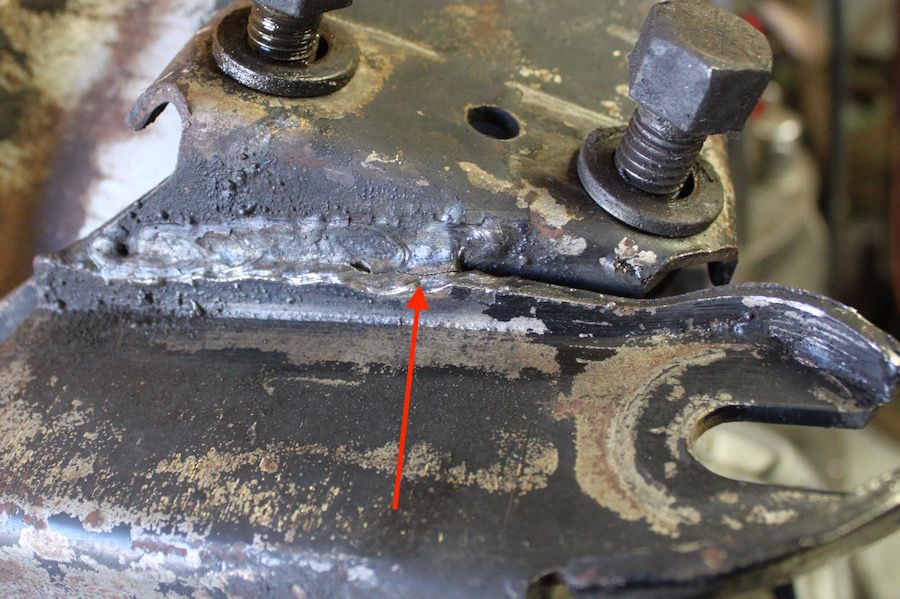

Folks, if you're working on your front ends, doing a re-build of your front suspension, or a general inspection, please give your K-frame a very good looking over. Pay special attention to the motor mount perches and the steering box mount.....and the tubes for the lower control arm bushings.

This one was TERRIBLE!!!!!

I ground out what welds I could get to with my angle grinder, fired up the welder, and while not museum quality....it's a helluva lot better than what it was.

View attachment 69 Cuda K-frame 001.jpg

View attachment 69 Cuda K-frame 002.jpg

View attachment 69 Cuda K-frame 003.jpg

View attachment 69 Cuda K-frame 004.jpg

View attachment 69 Cuda K-frame 005.jpg

View attachment 69 Cuda K-frame 006.jpg

View attachment 69 Cuda K-frame 007.jpg

View attachment 69 Cuda K-frame 008.jpg

View attachment 69 Cuda K-frame 009.jpg

This one was TERRIBLE!!!!!

I ground out what welds I could get to with my angle grinder, fired up the welder, and while not museum quality....it's a helluva lot better than what it was.

View attachment 69 Cuda K-frame 001.jpg

View attachment 69 Cuda K-frame 002.jpg

View attachment 69 Cuda K-frame 003.jpg

View attachment 69 Cuda K-frame 004.jpg

View attachment 69 Cuda K-frame 005.jpg

View attachment 69 Cuda K-frame 006.jpg

View attachment 69 Cuda K-frame 007.jpg

View attachment 69 Cuda K-frame 008.jpg

View attachment 69 Cuda K-frame 009.jpg