I'm currently trying to un-f$#k the brand new Classic Holley 600 CFM 4 barrel on my Chrysler 360 V8.

So, first of all, I'm a complete newbie when it comes to tuning carbs. I know some basic ideas like idle mixture screws and idle speed screws, but I'm still not very good.

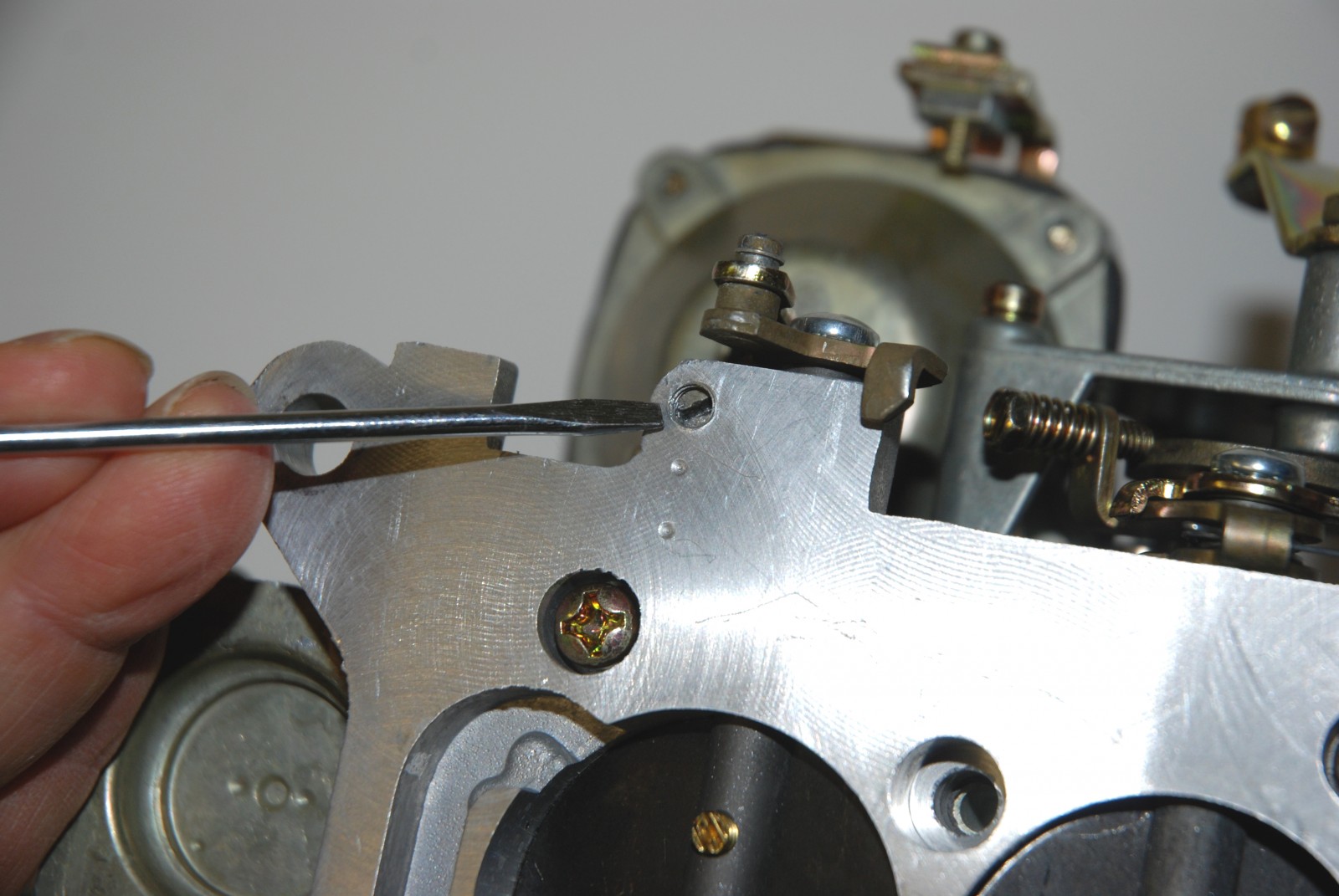

My current issue is that my AFR is really rich, so rich that I can clearly seek the smoke coming out of the tailpipes (with spastic, random backfires). My first concern is that the engine is idling a little high (in neutral), so I want to lower the idle speed. However, when I adjust the idle speed screw, nothing seems to happen.

So, first of all, I'm a complete newbie when it comes to tuning carbs. I know some basic ideas like idle mixture screws and idle speed screws, but I'm still not very good.

My current issue is that my AFR is really rich, so rich that I can clearly seek the smoke coming out of the tailpipes (with spastic, random backfires). My first concern is that the engine is idling a little high (in neutral), so I want to lower the idle speed. However, when I adjust the idle speed screw, nothing seems to happen.