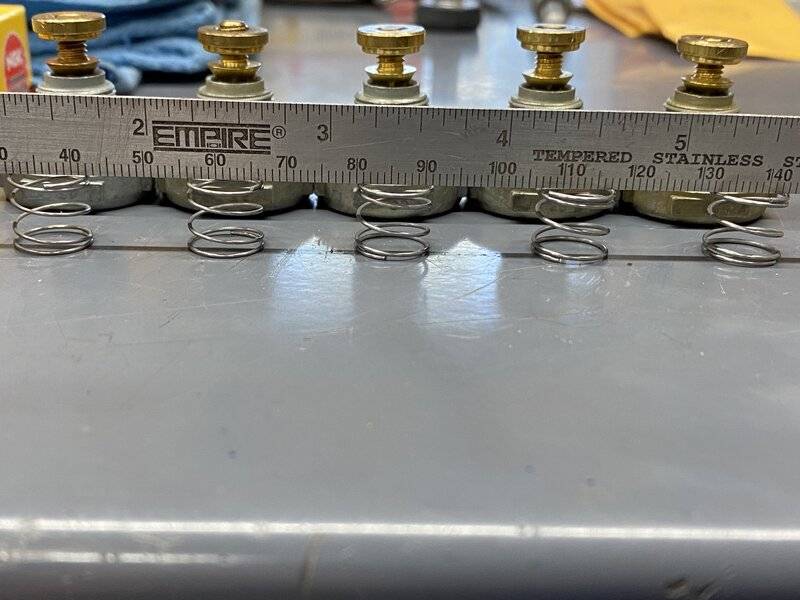

Tinkering out in the shop with some power valves after @RustyRatRod mentioned in another thread about using an e-clip to retain the disc to reassemble after a spring change, one possible method of disassembly/reassembly in order to use a heavier spring to create an 11.5-up power valve(s)

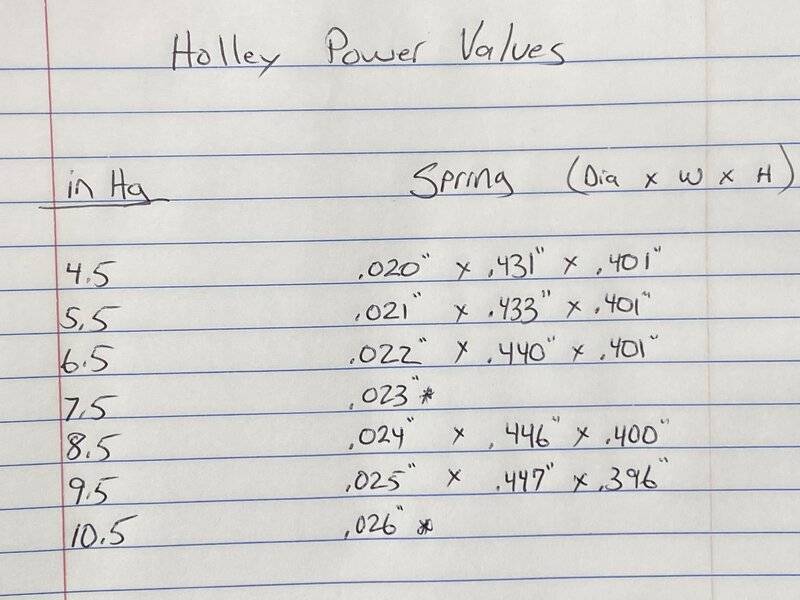

Removing the spring is obviously the easy part without cutting mods or damage. Sourcing a spring to create the correct value (in. Hg) not so much. I measured all the pv’s springs I have on hand as best I could (* in picture denotes PV I don’t have, the wire diameter shown is assumed) Seems each step up in rating has .001” thicker diameter wire and the overall width goes up and the height down slightly. Very hard to get an accurate height reading. A straight edge does lay pretty much flat across them.

Time to start looking for springs that could be cut down and ends formed to seat correctly. Would take some testing to ensure they open at the correct vacuum. Sure wokld be nice to have higher than 10.5 pv’s to try out. May be a bust but worth a try.

Removing the spring is obviously the easy part without cutting mods or damage. Sourcing a spring to create the correct value (in. Hg) not so much. I measured all the pv’s springs I have on hand as best I could (* in picture denotes PV I don’t have, the wire diameter shown is assumed) Seems each step up in rating has .001” thicker diameter wire and the overall width goes up and the height down slightly. Very hard to get an accurate height reading. A straight edge does lay pretty much flat across them.

Time to start looking for springs that could be cut down and ends formed to seat correctly. Would take some testing to ensure they open at the correct vacuum. Sure wokld be nice to have higher than 10.5 pv’s to try out. May be a bust but worth a try.

Last edited: