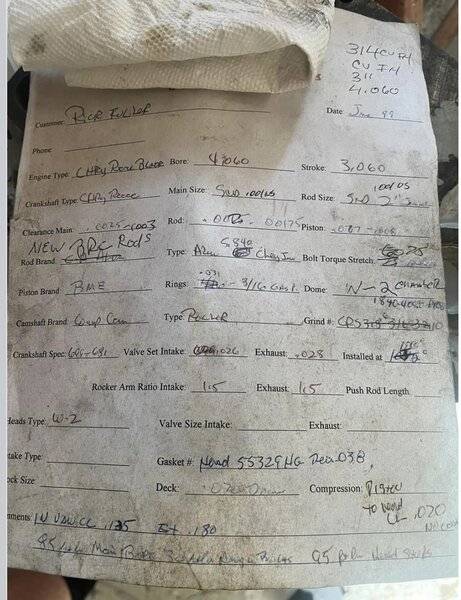

No mine.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

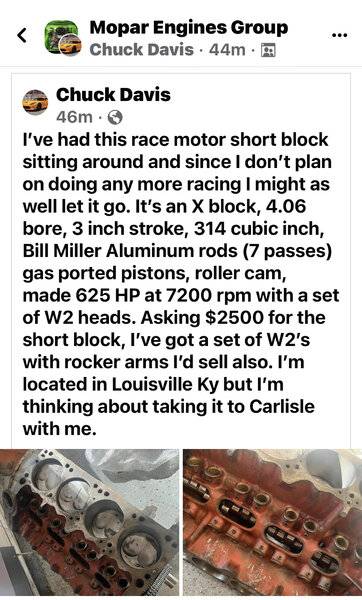

How long will this little buz saw engine last.

- Thread starter pittsburghracer

- Start date

-

Till those rods start stretching to the point of fatigue.

I asked the folks at Hughes Engines about aluminum rods and was told you won't have a problem with a engine that will never see more than 7,000 + rpm. As they called it a Street Engine. So I used them in a build back in 2004. That engine is still running today in a bracket car.

So take it for whatever. Just my experience with aluminum rods.

That thing would need a good going over. I wouldn't just stick it together.

So take it for whatever. Just my experience with aluminum rods.

That thing would need a good going over. I wouldn't just stick it together.

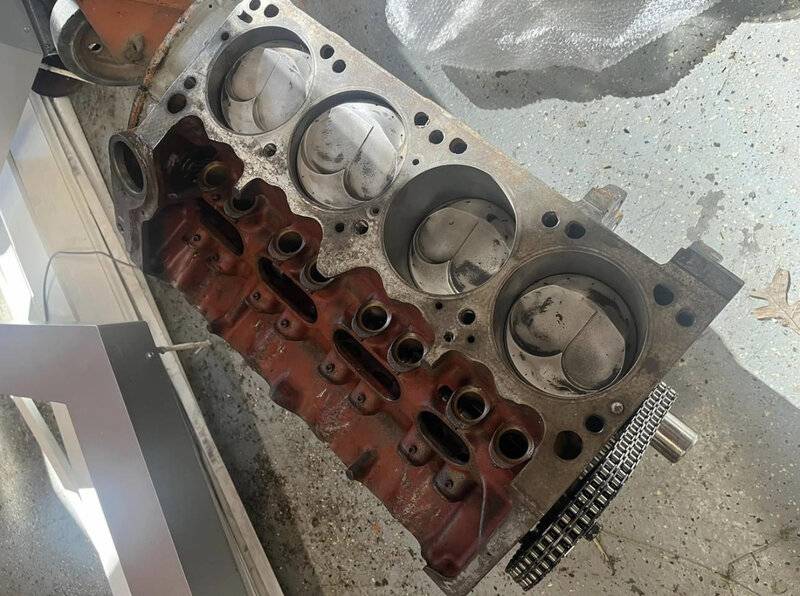

What are the Allen heads on the lifter bores for?

What are the Allen heads on the lifter bores for?

I was looking at that earlier too and couldn’t figure it out. Only thing that popped into my head was I wonder if one time something had oiling lines running to the lifters. Possibly the block could have been tubed and someone wanted some oiling. You got me?????

19DART66

Well-Known Member

If you look at the last two lifter bores at the back of the block(one on each side) they are drilled and tapped at a different angle. My thinking is, after who ever bushed the lifter bores drill through to the oil galley to feed oil to the lifters. Then tapped the outside holes hole and put the set screws in to plug the oil leak to the valley. Could be way off but that was my first thought.

Just saying, but what do I know (nothing). Its a cool engine. If the block is good, that would be the asking price right there, but you never know till its gone through. That block I believe has alot of life left in it if it is good. If I had the cabbage, it would be mine.Till those rods start stretching to the point of fatigue.

If you look at the last two lifter bores at the back of the block(one on each side) they are drilled and tapped at a different angle. My thinking is, after who ever bushed the lifter bores drill through to the oil galley to feed oil to the lifters. Then tapped the outside holes hole and put the set screws in to plug the oil leak to the valley. Could be way off but that was my first thought.

On my phone I can’t see bushings. I’ll have to check on my computer one of these days.

junkyardhero

Well-Known Member

i think the bores are bushed and those are the set screws to lock them in?What are the Allen heads on the lifter bores for?

i don't know much about the architecture of those blocks and that's just a wag.

I can't see down the lifter bores really well, but it looks like they may be cut for keyed lifters. Set screws to keep them from spinning possibly?

Last edited:

Chuck was making regular visits to Savannah GA area so if you live down that way he will meet you going thru GA etc / I have done business with him SOLID FELLOW.

My thought too.i think the bores are bushed and those are the set screws to lock them in?

My thought too.

I have a shortblock I built that I bought the parts from a guy that had the lifter bores sleeved and it doesn’t have set screws holding the sleeves in. Supposed to be a proper fit on them.

gzig5

Well-Known Member

My original thought was that the screws were machined on the end to act as keys for roller lifters, but the last hole by the oil pump drive is at an angle and unless the lifter can accommodate that, that theory isn't supported. Looks like a fun motor. I've always wondered about the longevity of aluminum rods, seemed to be a "race only" thing that needed to be looked after closely.I can't see down the lifter bores really well, but it looks like they may be cut for keyed lifters. Set screws to keep them from spinning possibly?

I bought a W2 intake off of him, nice guy. He is the kind of guy that makes you feel at home as soon as you meet him.

We had agreed upon a price, and he knocked it down a bit because I drove a few hours to pick it up.

I know he is a member here, I think HemiChuck is his fabo name.

We had agreed upon a price, and he knocked it down a bit because I drove a few hours to pick it up.

I know he is a member here, I think HemiChuck is his fabo name.

Dartswinger70

Well-Known Member

Kentucky? that seems like its close to Uncle Tony maybe he can go over it a bit get it "freshened up..." (sorry i just had to...)

-