KitCarlson

Well-Known Member

When I built my electronic advance ignition, part of the plan was to evaluate ignition coils. I got side tracked when looking at RPM data logs, I discovered that my transmission was starting to slip. So I rebuilt it .... and did not get back to making an ignition coil test setup.

There have been recent posts about can coils vs E-core. Specifications provided by vendors are often poor. It is still possible to test a coil and evaluate the important coil parameters.

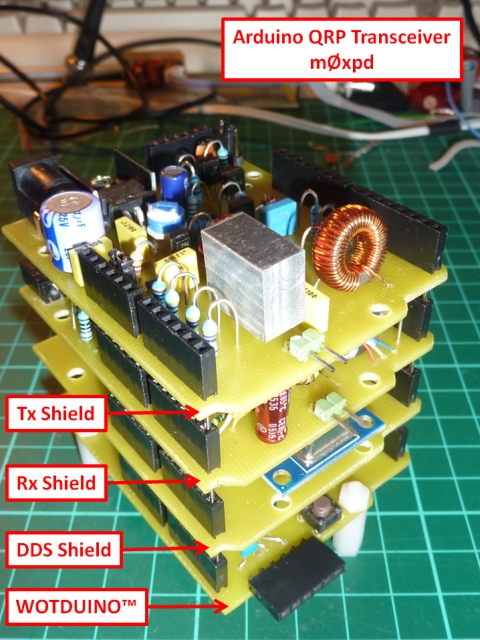

I recently found a Arduino Nano board for less than $10. It has an Atmel AVR ATmega328p micro controller. I am familiar with it because I first worked with a similar predecessor about 13 years ago.

I started with the code developed for the injector tester, took out features and added some. The user interface is via USB using a terminal emulator. The terminal lets me use keys to send characters to the tester, and the tester sends characters back that are displayed on the terminal. So there is no hardware like a LCD, or custom keypad.

The coil driver consists of a IGBT a couple resistors and a small transistor. The transistor and current shunt resistor serve as a current limit. The current limit is a means to eliminate a ballast resistor. It is set to about 6.5A.

The programming consists of a user interface, so the test parameters of RPM, dwell, minimum spark duration, counts and start can be controlled.

The test parameters are then used to operate an internal timer to control the coil charge, and off intervals.

There is a means to monitor the charge current, and spark discharge current using shunts and a scope. The bottom trace is the coil current, the top trace is the spark current. Spark current is negative.

The 6000 RPM test shows that the reduced dwell and short spark duration, helps build coil energy. I can write more about that if there is interrest.

There have been recent posts about can coils vs E-core. Specifications provided by vendors are often poor. It is still possible to test a coil and evaluate the important coil parameters.

I recently found a Arduino Nano board for less than $10. It has an Atmel AVR ATmega328p micro controller. I am familiar with it because I first worked with a similar predecessor about 13 years ago.

I started with the code developed for the injector tester, took out features and added some. The user interface is via USB using a terminal emulator. The terminal lets me use keys to send characters to the tester, and the tester sends characters back that are displayed on the terminal. So there is no hardware like a LCD, or custom keypad.

The coil driver consists of a IGBT a couple resistors and a small transistor. The transistor and current shunt resistor serve as a current limit. The current limit is a means to eliminate a ballast resistor. It is set to about 6.5A.

The programming consists of a user interface, so the test parameters of RPM, dwell, minimum spark duration, counts and start can be controlled.

The test parameters are then used to operate an internal timer to control the coil charge, and off intervals.

There is a means to monitor the charge current, and spark discharge current using shunts and a scope. The bottom trace is the coil current, the top trace is the spark current. Spark current is negative.

The 6000 RPM test shows that the reduced dwell and short spark duration, helps build coil energy. I can write more about that if there is interrest.