I want to raise my head cc's from 60 to 68 to use available pistons. I'm trying to avoid a 13cc dish in favor of a 5.5cc flat top to get the compression around 11.3-11.5. The dish is 1.450 compression height, the flat top is 1.465 compression height and matches my current 23.5cc dish piston. I don't want to deck the block. Opinions, feedback?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Increase Head CC's

- Thread starter srduster340

- Start date

-

What cylinder heads?

Bobzilla

Well-Known Member

Edited to remove my comments after finding your old thread on this.I want to raise my head cc's from 60 to 68 to use available pistons. I'm trying to avoid a 13cc dish in favor of a 5.5cc flat top to get the compression around 11.3-11.5. The dish is 1.450 compression height, the flat top is 1.465 compression height and matches my current 23.5cc dish piston. I don't want to deck the block. Opinions, feedback?

Custom Pistons

Last edited:

Have you cc’d your heads? I don’t know of any open chamber heads with 60 cc chambers unless they have been milled. Post pictures of your heads.

gzig5

Well-Known Member

Cut them on the band saw and send it. I hear that's all the rage now.Buy the special order thick head gaskets or cut the tops of the pistons

Polish the chambers.

mcodecuda

Senior Member

Cometic head gaskets. You can get them in any thickness. I’m using two different thickness gaskets on my new motor in order to correct the deck height difference.

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 25,809

- Reaction score

- 13,117

Opinions, feedback?

my alloy-headed 367 has run 11.3 Scr with a [email protected] cam, on 87E10, at WOT, running 106 in the Qtr @3650 pounds and at 719ft elevation, on it's one and only run.

I only ran it like that, as my DD, for 1 summer/5 months.

My compression tester, which I believe to be accurate, measured over 190 psi.

Jus saying.................

I should have gave more information. I purchased a set of Trick Flow 190's. The chambers are 60cc's advertised. Bore is currently 4.06 with a 4.00" crank, standard length Scat rods, zero deck height, .039 thick gasket, 4.1 bore. I'm trying to match the static compression ratio of11.3-11.5, cranking compression around 190-195, intake closing around 70 degrees give or take a few.

Thicker head gaskets will ruin my quench.Buy the special order thick head gaskets or cut the tops of the pistons

Then mill the pistons to maintain the quench. I cut 0.080" off the last set to run pump gas, and I have been putting valve notches in all my pistons for over 40 years. Just need a Bridgeport or equivalent, or you'll have to pay some one to do it for you.

Phreakish

Well-Known Member

I don't get it.

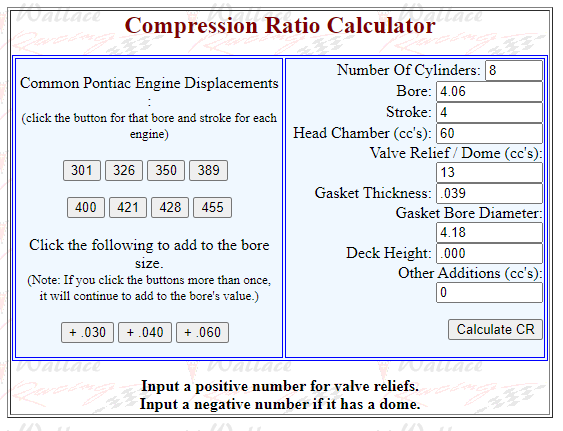

With a 4.06 bore, 4" stroke, 60cc head chamber, 13cc of piston dish and valve relief, .039 gasket with a 4.18 gasket bore (Felpro 1008) and a 0 deck, I get 11.38:1 SCR. If you're shooting for 11.3-11.5 I don't see why you need to change your CC volume at all? Build it with the 13cc piston and you're golden. The dish on the Icon's doesn't really give up any quench since the resulting shape is basically a stepped piston like the KB356.

With a 4.06 bore, 4" stroke, 60cc head chamber, 13cc of piston dish and valve relief, .039 gasket with a 4.18 gasket bore (Felpro 1008) and a 0 deck, I get 11.38:1 SCR. If you're shooting for 11.3-11.5 I don't see why you need to change your CC volume at all? Build it with the 13cc piston and you're golden. The dish on the Icon's doesn't really give up any quench since the resulting shape is basically a stepped piston like the KB356.

1WildRT

Well-Known Member

Reducing chamber volume is easy... Trying to increase chamber volume ain't easy... I've spent some time grinding on a set of big block 915's looking for 7-8cc's, I got 3-4.. I bolted the heads to the bare block I was using, then went through the bottom of the cylinders to scribe the bore on the head... Then blended the chamber out to that line, I blended the hard line from the cavity of the chamber to the flat portion of the chamber... There just isn't must you can cut, the valves establish most of the shape of the chamber...

As you mentioned you don't want to sacrifice quench so thick head gaskets are out... if there's enough material you can machine the half of the piston dome that's under the chamber, not the quench side... eight cc's there wouldn't be to hard, but the easy way was to pony up for a custom piston

Everyone get's hung up on the cost of custom pistons but using off the shelf pistons when you have a goal the doesn't match what's available often winds up being more expensive then sucking it up in the first place... DAMHIK

And @Phreakish typed out the best answer while I was typing this out....

As you mentioned you don't want to sacrifice quench so thick head gaskets are out... if there's enough material you can machine the half of the piston dome that's under the chamber, not the quench side... eight cc's there wouldn't be to hard, but the easy way was to pony up for a custom piston

Everyone get's hung up on the cost of custom pistons but using off the shelf pistons when you have a goal the doesn't match what's available often winds up being more expensive then sucking it up in the first place... DAMHIK

And @Phreakish typed out the best answer while I was typing this out....

The 13cc Icon dish piston has a 1.450 compression height, I'll have to deck the block again to use that piston. If I have to, I will look into a custom 13cc dish piston at 1.465 compression height so I won't have to. I prefer a flat top piston but the 13cc dish is probably the better option than increasing head cc's.I don't get it.

With a 4.06 bore, 4" stroke, 60cc head chamber, 13cc of piston dish and valve relief, .039 gasket with a 4.18 gasket bore (Felpro 1008) and a 0 deck, I get 11.38:1 SCR. If you're shooting for 11.3-11.5 I don't see why you need to change your CC volume at all? Build it with the 13cc piston and you're golden. The dish on the Icon's doesn't really give up any quench since the resulting shape is basically a stepped piston like the KB356.

View attachment 1716093417

What is your measured static compression ratio AS IS with the head gaskets you plan to use? With aluminum heads and good quench, you should have detonation resistance to around 12:1 or so.

Phreakish

Well-Known Member

The 13cc Icon dish piston has a 1.450 compression height, I'll have to deck the block again to use that piston. If I have to, I will look into a custom 13cc dish piston at 1.465 compression height so I won't have to. I prefer a flat top piston but the 13cc dish is probably the better option than increasing head cc's.

Then buy the 1.465" 5cc ones and let a shop add a 13cc relief ferchrissakes. You're already paying for forged, might as well get it right. I bet if you call icon they could add it for not much and still ship them in a reasonable amount of time.

I didn't know I could have that done. I certainly will contact Icon and see. Thanks!Then buy the 1.465" 5cc ones and let a shop add a 13cc relief ferchrissakes. You're already paying for forged, might as well get it right. I bet if you call icon they could add it for not much and still ship them in a reasonable amount of time.

MopaR&D

Nerd Member

Measure the chamber volumes yourself, kits to do it are cheap and it's a simple process. I'd be surprised if they came out same as advertised. Usually it's a bit over because they have to account for tolerance in manufacturing and it's safer for the chambers to be larger than spec vs. smaller. Unless perhaps Trick Flow CNC machines the chambers too, which I doubt because that would add considerably to cost with minimal real benefit to the intended customer.

-