grassy

Well-Known Member

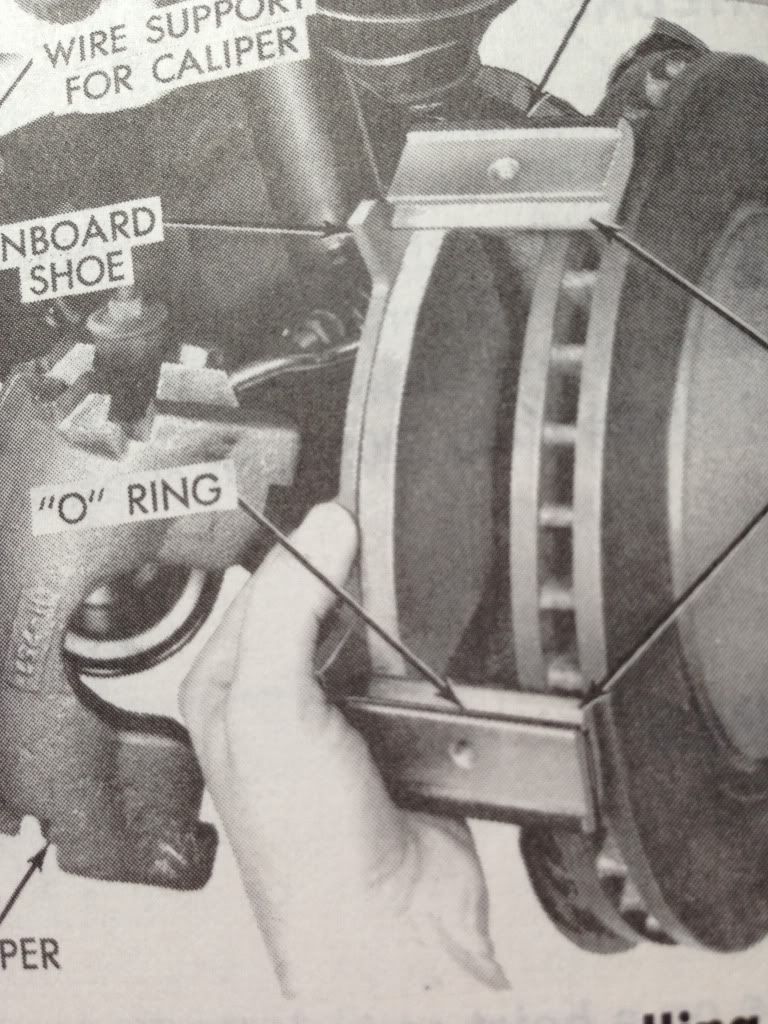

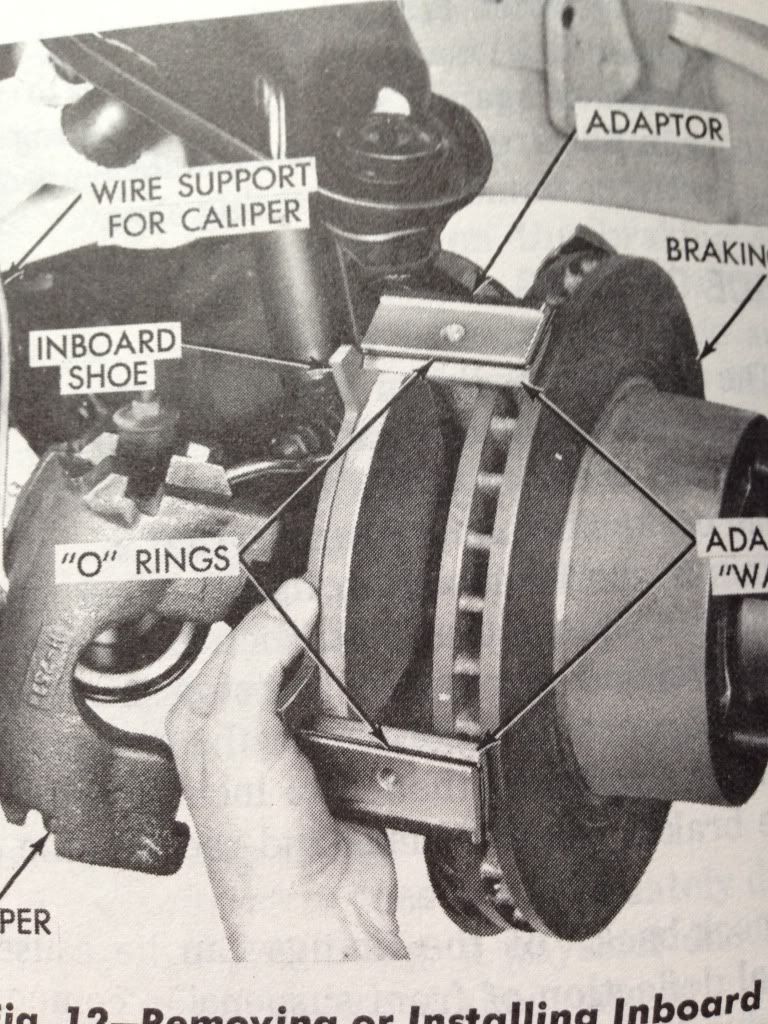

I was installing my calipers today and something doesnt look right

see pics below:

Brake kit

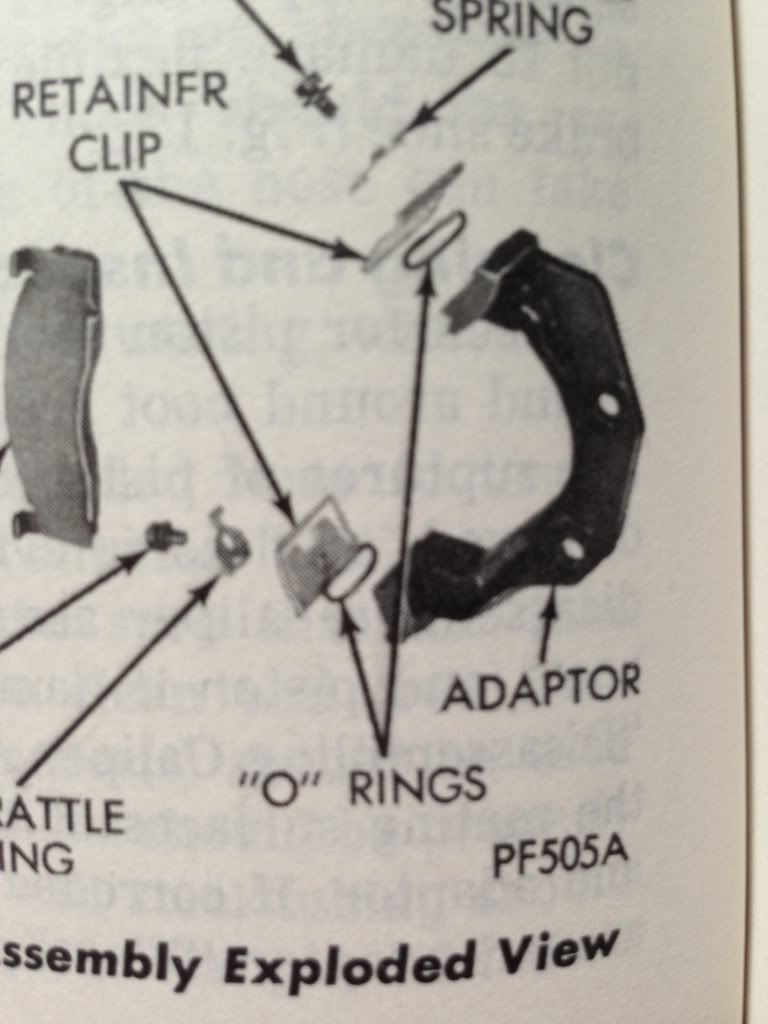

Even with the piston pushed all the way back with the pads, it is a tight fit. Could I have the "c" clamps on the wrong side ?

That retaining clip on the top really doesnt fit right..

In the kit, what are the rubber for and where do the other clips fit ?

Not on this topic but it puzzles me..

[FONT="] I installed my new idler arm (75 duster) and torqued it as per service manual to 70 pounds...unfortunately, it locks the steering...is the torque figure off in the service manual ?

[/FONT]

Brake kit

Even with the piston pushed all the way back with the pads, it is a tight fit. Could I have the "c" clamps on the wrong side ?

That retaining clip on the top really doesnt fit right..

In the kit, what are the rubber for and where do the other clips fit ?

Not on this topic but it puzzles me..

[FONT="] I installed my new idler arm (75 duster) and torqued it as per service manual to 70 pounds...unfortunately, it locks the steering...is the torque figure off in the service manual ?

[/FONT]