Ok, I did a quick search and didn't find everything I was looking for, so here goes.

I "lost" a lash cap on my 340. Was driving home and suddenly had a "tapping" valve train noise, exactly like a noisy (loose) rocker. Didn't lose power, didn't run rough, so I finished my drive home (I know, probably not the best idea). Less than 10 minutes.

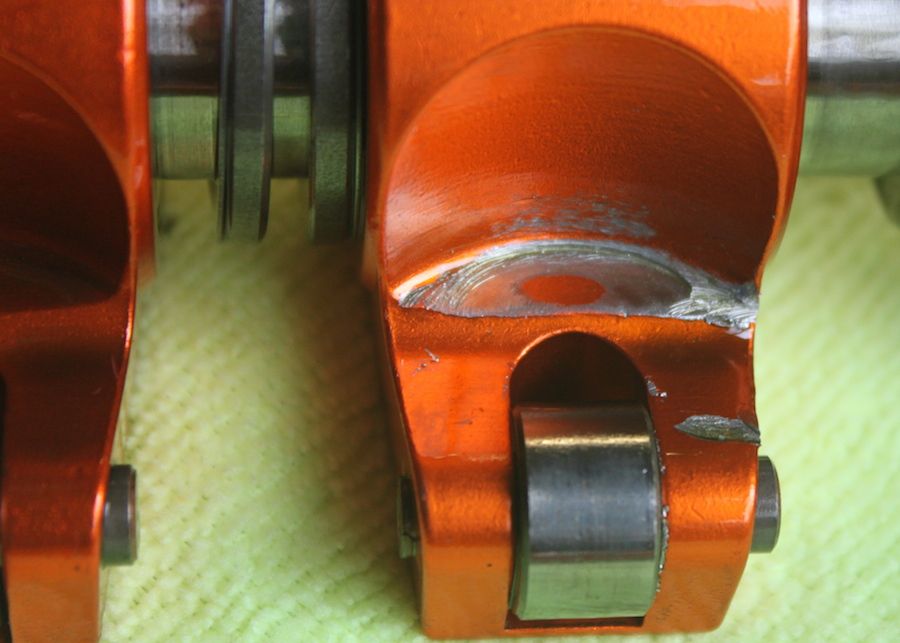

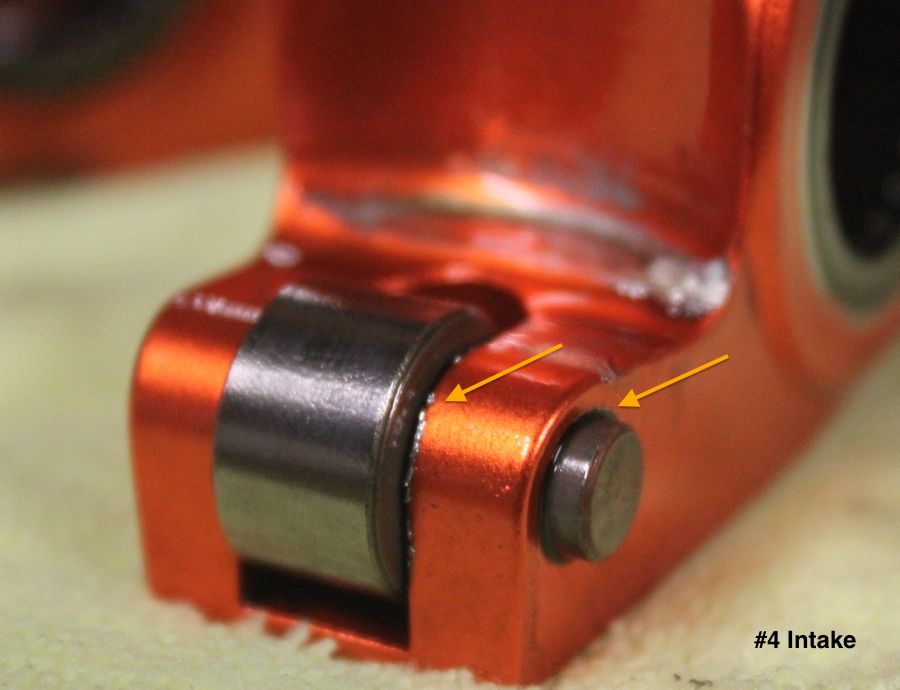

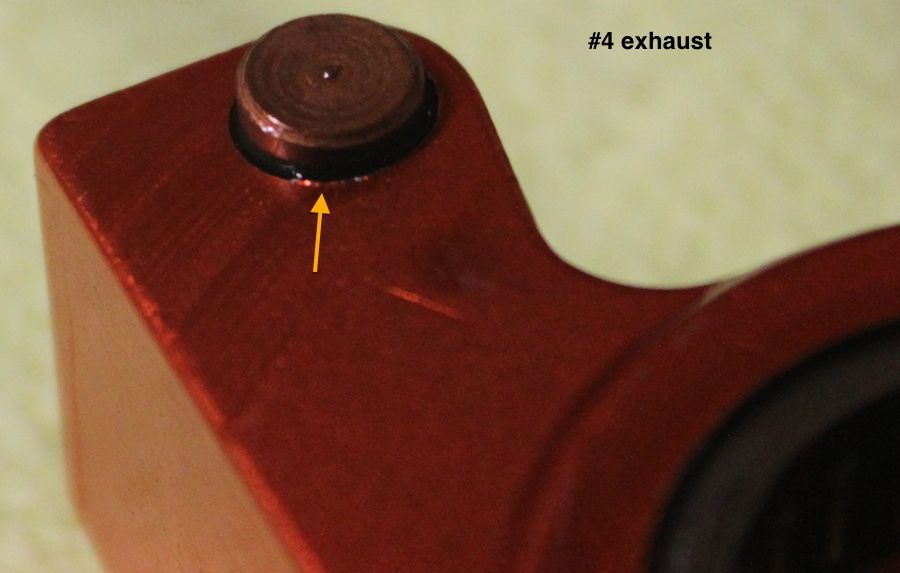

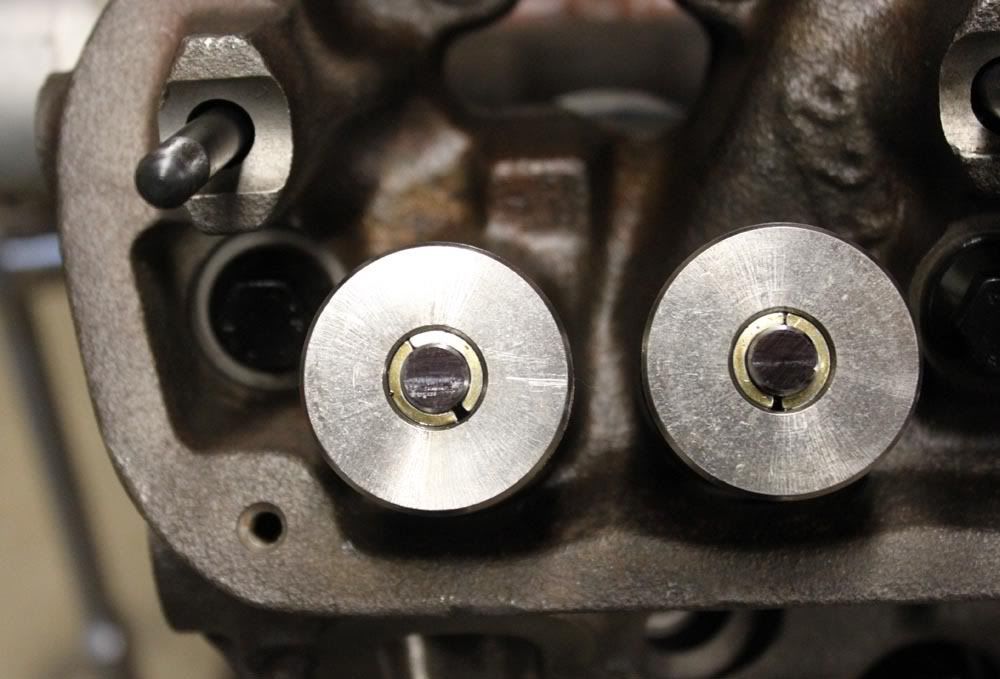

Pulled the valve covers and found that #4 intake had lost its lash cap. I run Comp Cams .080" lash caps with my Harland Sharp roller rockers to correct my rocker geometry. I managed to find and retrieve the lash cap from the cam valley rayer:. Surprisingly enough, it was on the other side of the valley, between the lifters on #3. Nothing on the lash cap looks damaged, although you can see a slight wear pattern from the rocker on the lash cap.

rayer:. Surprisingly enough, it was on the other side of the valley, between the lifters on #3. Nothing on the lash cap looks damaged, although you can see a slight wear pattern from the rocker on the lash cap.

Engine is a '68 340, I have a Lunati #60404 cam in it. It has Lunati hydraulic lifters, Smith Bros pushrods, Harland Sharp roller rockers, and the Comp .080" lash caps. The engine has 1,100 miles on it, 600 since the last oil change and rocker adjustment. I just did a quick check, but the rocker adjustment doesn't seem far off anywhere else. I haven't pulled the rockers yet, but nothing in the valvetrain looks broken or damaged. Obviously with the rockers still on I can't see everything.

This is the first time I've run lash caps on anything, so I've got some questions-

How common is having a lash cap come off? Is this something that happens from time to time, or is it usually a symptom of a bigger problem than just a loose valve adjustment? I know that its not unusual to need some occasional valve readjustment, especially on a new engine, but I keep thinking the worst. :violent1:

My plan is to pull the rockers, inspect everything for damage, replace the lash cap, button it back up and reset the valve adjustment. Is there anything else I should be doing, replacing, or checking before I get into this?

I "lost" a lash cap on my 340. Was driving home and suddenly had a "tapping" valve train noise, exactly like a noisy (loose) rocker. Didn't lose power, didn't run rough, so I finished my drive home (I know, probably not the best idea). Less than 10 minutes.

Pulled the valve covers and found that #4 intake had lost its lash cap. I run Comp Cams .080" lash caps with my Harland Sharp roller rockers to correct my rocker geometry. I managed to find and retrieve the lash cap from the cam valley

Engine is a '68 340, I have a Lunati #60404 cam in it. It has Lunati hydraulic lifters, Smith Bros pushrods, Harland Sharp roller rockers, and the Comp .080" lash caps. The engine has 1,100 miles on it, 600 since the last oil change and rocker adjustment. I just did a quick check, but the rocker adjustment doesn't seem far off anywhere else. I haven't pulled the rockers yet, but nothing in the valvetrain looks broken or damaged. Obviously with the rockers still on I can't see everything.

This is the first time I've run lash caps on anything, so I've got some questions-

How common is having a lash cap come off? Is this something that happens from time to time, or is it usually a symptom of a bigger problem than just a loose valve adjustment? I know that its not unusual to need some occasional valve readjustment, especially on a new engine, but I keep thinking the worst. :violent1:

My plan is to pull the rockers, inspect everything for damage, replace the lash cap, button it back up and reset the valve adjustment. Is there anything else I should be doing, replacing, or checking before I get into this?