So I was reading the other day that the BMW 1 series uses 2 mismatched turbos to deal with lag and to keep boost at all rpms, Ive heard Porsche and Ford have similar systems but those are based on very expensive turbos with variable veins and strange vacuum/ecu activation. This setup is more like the small turbo takes the place of the waste gate which just seems simple. maybe someone has tried or knows a way to use two different turbos together? I imagine you cant just throw one small turbo on the left and one big turbo on the right because of the uneven back pressure? Maybe you would need to merge both sides, y pipe to two turbos and waste gates then merge back into the intake? I have seen sequential turbo where you have one turbo feed the other but this seems like you would still have bottleneck so almost pointless.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

mismatched non seqeuntial turbo?

- Thread starter Jimmy

- Start date

-

Apparently it works fine !!

I suppose if your a large German car manufacturer (which I'm pretty far from) but what would be the pitfalls and issues associated with doing this on a small block on a budget? Any ideas? What kind of offset would work the best? Would you want the biggest and smallest? one slightly bigger? two the same with different turbine wheels? Anyone interested in a no lag, constant boost a-body or is it just me?

Actually, looking at the flow chart, it appears that at low speeds, the small one does all the work and also keeps the big turbo spooling.

At high speed, all the airflow goes thru the big turbo.

Best of both worlds.

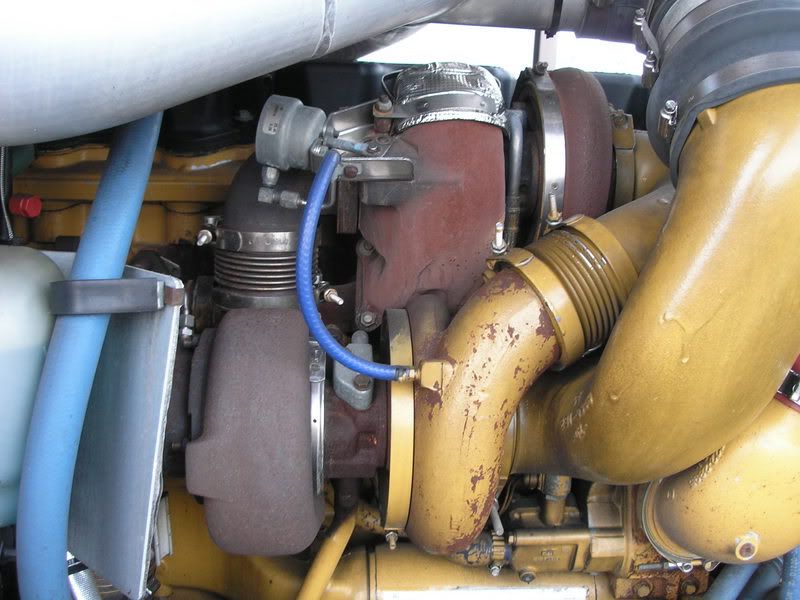

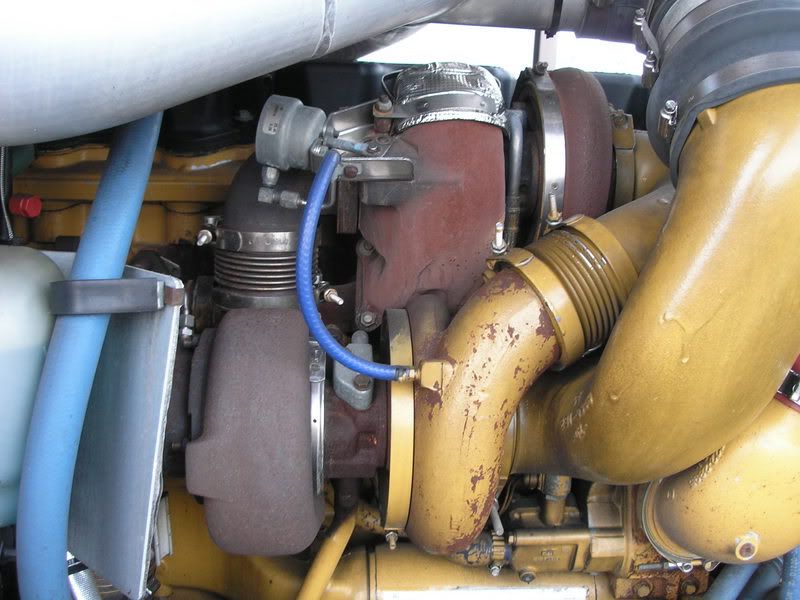

This is my favorite set-up. 15 liter Cat 550 hp Bout 2000ft/lbs of torque

[ame="http://www.youtube.com/watch?v=7izbcCDcyLQ&feature=related"]http://www.youtube.com/watch?v=7izbcCDcyLQ&feature=related[/ame]

At high speed, all the airflow goes thru the big turbo.

Best of both worlds.

This is my favorite set-up. 15 liter Cat 550 hp Bout 2000ft/lbs of torque

[ame="http://www.youtube.com/watch?v=7izbcCDcyLQ&feature=related"]http://www.youtube.com/watch?v=7izbcCDcyLQ&feature=related[/ame]

33 psi, now that's a well built system. Hard to tell but it looks like it's done the same way, except it appears to be sequential and just a tad bigger, the cold side looks like a 4" header, gives me a headache trying to figure out where all the pipes go. interested in the waste-gate connection, is it internal on one and actuated by the other?

So no one knows, is interested, has tried? Where are my boost experts to tell me I can't do it with two garrets and a bunch of pipe? Cus I'm telling you right now I'm going for it unless someone talks some sense into me and I have no clue what I'm doing!!:toothy10:

Can someone at least tell me how I should overlay compressor maps and what to look for? I know the surge line is most important but where should one drop off in relation to other in the rpm range? My goal is 6000rpm, 13:1 compression, 500hp so according to various online calculators I need 10 PSI and 52 pounds air flow at 650cfm. Oh its a 318.

Can someone at least tell me how I should overlay compressor maps and what to look for? I know the surge line is most important but where should one drop off in relation to other in the rpm range? My goal is 6000rpm, 13:1 compression, 500hp so according to various online calculators I need 10 PSI and 52 pounds air flow at 650cfm. Oh its a 318.

I got this much out of it.....

Air comes into bottom turbo which feeds the top one.

Exhaust comes out of engine thru top turbo which feeds the bottom one and goes to the exhaust system out of the bottom one.

Plumbers Nightmare!!

And you are correct about the wastegate.

Air comes into bottom turbo which feeds the top one.

Exhaust comes out of engine thru top turbo which feeds the bottom one and goes to the exhaust system out of the bottom one.

Plumbers Nightmare!!

And you are correct about the wastegate.

so it is pretty similar, but you would think that only having one path of flow would create a lot of back pressure, I suppose that's why the waste gate is actuated by the smaller turbo? They have it a little easier since they can rout it all off one exhaust manifold. Imagine the piping if they had to bring the other side around.

Every once in a while I would get people that want to park next to the truck for miles going down the Interstate, which is unsafe in so many ways and also creates a traffic jam. I have been known to play with the throttle to get the turbos to whistle at point where it hurts their ears.

Sometimes I have to ride the brakes just a bit to induce more boost but usually about 5 seconds of it and they move on.

Sometimes I have to ride the brakes just a bit to induce more boost but usually about 5 seconds of it and they move on.

-