BillGrissom

Well-Known Member

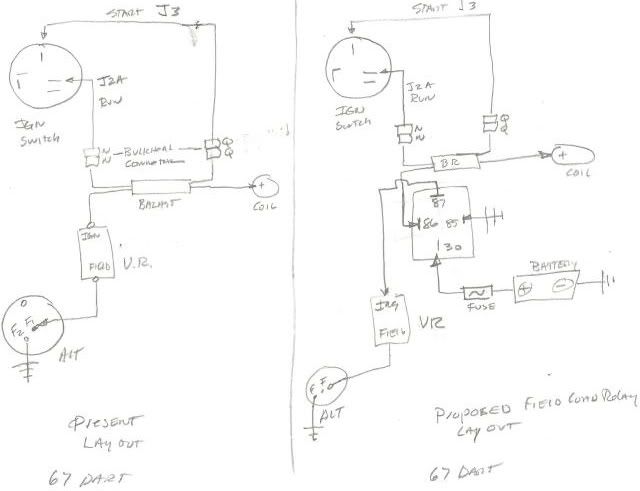

As promised, details of how I modernized the engine wiring in my 65 Dart 273. Glad to answer questions.

I got a Power Distribution Center (PDC) from a 95 Jeep Grand Cherokee. I expected the relay terminals would be Packard 57 type, but were a variant of the square Ford type. I found the ones for the small fuses (left in 1st photo), but only ones too thick for the relays (middle) unless squashed a bit. I ended up splicing to existing wires, rather than new terminals on new wires. I suggest cutting as much harness as possible. I ended up removing all wires from the PDC and starting from scratch since existing wires were the wrong size or branching.

The PDC eliminates all relays on the firewall, plus adds relays for high/low beam, ignition, and fuel pump. I put the voltage regulator beside the alternator (2-field wire type). I ran wires in smooth PVC sheath (SPC Tech), which is easier to clean than split loom, but you must pull the wires thru. I used 20 awg ribbon cable for most wires to the bulkhead since they simply actuate relays. I saved my existing wires by pulling out the 57 terminals (right in 1st photo) and crimp+soldering on new ones. Note how you squeeze longitudinally to remove them. I used the light harness from a 74 Dart, which adds a ground wire. I had to reuse my bulkhead connector housings since the 74 Dart's are different. I don't have the 3rd connector since my wiper wiring is under-dash.

The power wiring requires the most explanation. My 65 Dart has large lugs for power leads, so no concern with melting spade terminals as in later years. Interestingly, my 64 doesn't have those and runs the leads thru a grommet hole (at least someone did). I ran 8 awg from the battery to the "BATT" lug, w/ two 12 awg on the dash side, one to the ammeter and another for future loads like a power seat. Ideally, all current from the battery flows thru the ammeter to be measured. Of course, not the high starter current and the factory didn't meter the horn or starter relay currents.

The alternator supplies the PDC, then a 12 awg wire runs to the "ALT" lug. Under-dash supplies branch from there before the ammeter. I installed the later square-back alternator, which supposedly outputs 70 A. Since that could fry my ammeter and wiring, I shunt extra current to the battery, bypassing the ammeter. I use two parallel diodes (Vishay VS-175BGQ045), soldered back-back. They are rated 170A, but more important is that they have a good heat sink. I bolted them to my Battery Brain as shown (under silicone tape), which is much copper going to the battery as a heat sink.

For the diode design, I first measured the drop across the power lugs in my 65 Newport as 0.72 V at full scale (full field on alternator). Silicon diodes have about that forward drop, so seemed a good fit. In the Dart, I measured 30 A at full-field (external ammeter). My ammeter then read ~1/5 scale and I measured a 0.25 V drop across the diodes. The manufacturer's plot shows ~20 A thru the diodes at that drop if 70 F, so ~10 A thru my ammeter. The power dissipated in the diodes would only be 5 W. If I could get 100 A output from my alternator, the diodes would drop ~0.6 V, my ammeter would read almost full-scale and the diodes would dissipate ~45 W, probably warm but not super hot. Had I rev'ed the engine I might have seen more output. I have fuses on all power leads, at least 80 A, mainly to protect from a dead short.

You can read elsewhere about the Battery Brain. I started putting one on all my cars 3 months ago and they already saved me from being stranded a few times (those batteries tested bad later at Autozone).

On the dash harness, I just repaired all the prior hacks like butt crimps, missing turn signal connector, and added an ACC relay. I put runs in split loom since the factory wrap was gone.

It all looks simple when done, but weeks of work. Don't imagine you can do similar in an afternoon, and no I am not soliciting to work on your wiring. I limit my effort to offering encouragement only. Enjoy, take pride in your A body, and don't be a hack.

I got a Power Distribution Center (PDC) from a 95 Jeep Grand Cherokee. I expected the relay terminals would be Packard 57 type, but were a variant of the square Ford type. I found the ones for the small fuses (left in 1st photo), but only ones too thick for the relays (middle) unless squashed a bit. I ended up splicing to existing wires, rather than new terminals on new wires. I suggest cutting as much harness as possible. I ended up removing all wires from the PDC and starting from scratch since existing wires were the wrong size or branching.

The PDC eliminates all relays on the firewall, plus adds relays for high/low beam, ignition, and fuel pump. I put the voltage regulator beside the alternator (2-field wire type). I ran wires in smooth PVC sheath (SPC Tech), which is easier to clean than split loom, but you must pull the wires thru. I used 20 awg ribbon cable for most wires to the bulkhead since they simply actuate relays. I saved my existing wires by pulling out the 57 terminals (right in 1st photo) and crimp+soldering on new ones. Note how you squeeze longitudinally to remove them. I used the light harness from a 74 Dart, which adds a ground wire. I had to reuse my bulkhead connector housings since the 74 Dart's are different. I don't have the 3rd connector since my wiper wiring is under-dash.

The power wiring requires the most explanation. My 65 Dart has large lugs for power leads, so no concern with melting spade terminals as in later years. Interestingly, my 64 doesn't have those and runs the leads thru a grommet hole (at least someone did). I ran 8 awg from the battery to the "BATT" lug, w/ two 12 awg on the dash side, one to the ammeter and another for future loads like a power seat. Ideally, all current from the battery flows thru the ammeter to be measured. Of course, not the high starter current and the factory didn't meter the horn or starter relay currents.

The alternator supplies the PDC, then a 12 awg wire runs to the "ALT" lug. Under-dash supplies branch from there before the ammeter. I installed the later square-back alternator, which supposedly outputs 70 A. Since that could fry my ammeter and wiring, I shunt extra current to the battery, bypassing the ammeter. I use two parallel diodes (Vishay VS-175BGQ045), soldered back-back. They are rated 170A, but more important is that they have a good heat sink. I bolted them to my Battery Brain as shown (under silicone tape), which is much copper going to the battery as a heat sink.

For the diode design, I first measured the drop across the power lugs in my 65 Newport as 0.72 V at full scale (full field on alternator). Silicon diodes have about that forward drop, so seemed a good fit. In the Dart, I measured 30 A at full-field (external ammeter). My ammeter then read ~1/5 scale and I measured a 0.25 V drop across the diodes. The manufacturer's plot shows ~20 A thru the diodes at that drop if 70 F, so ~10 A thru my ammeter. The power dissipated in the diodes would only be 5 W. If I could get 100 A output from my alternator, the diodes would drop ~0.6 V, my ammeter would read almost full-scale and the diodes would dissipate ~45 W, probably warm but not super hot. Had I rev'ed the engine I might have seen more output. I have fuses on all power leads, at least 80 A, mainly to protect from a dead short.

You can read elsewhere about the Battery Brain. I started putting one on all my cars 3 months ago and they already saved me from being stranded a few times (those batteries tested bad later at Autozone).

On the dash harness, I just repaired all the prior hacks like butt crimps, missing turn signal connector, and added an ACC relay. I put runs in split loom since the factory wrap was gone.

It all looks simple when done, but weeks of work. Don't imagine you can do similar in an afternoon, and no I am not soliciting to work on your wiring. I limit my effort to offering encouragement only. Enjoy, take pride in your A body, and don't be a hack.