thrustbucket

Member

I've been working on a 1998 Dodge Dakota Gen III swap for about a year now. Its a street-truck build on a budget. 2007 5.7L, fully rebuilt with stock 3.92 bore, MDS delete, Mancini drag-pack style intake, 750 demon vac secondary carb, Hemi 6, and 44RE, toughened up with a shift kit, HP clutches and steels, 8.25" rear rebuilt with 4.56 gears and track-loc) Goal is around 400hp at the crank.

I apologize for the insane length of this. But, it's a long story.

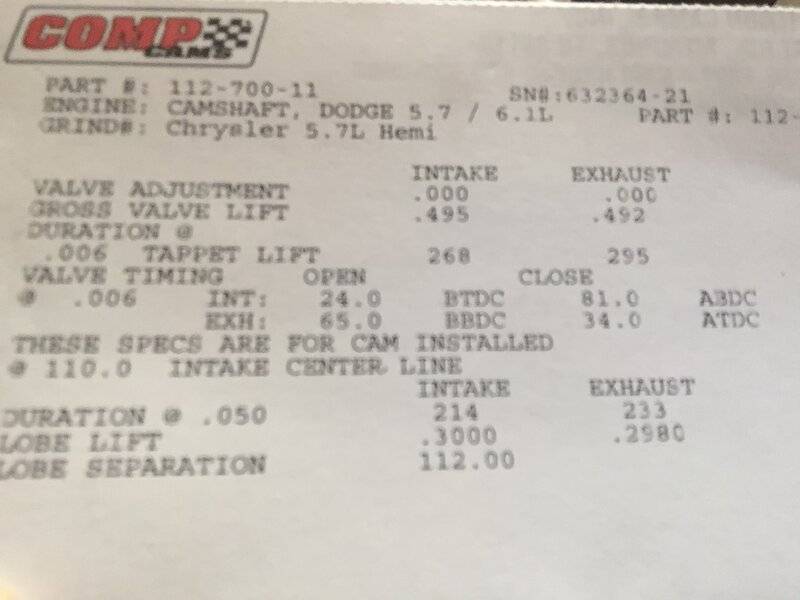

I purchased and installed a Comp-Cams Thumper Cam. (112-700-11)

First, I know the Thumper probably has a little too much overlap for the single plane. But, the specs looked more attractive to me than the Comp-Cams Stage 1 NSR cam, It is a budget build and I was focused on reusing as much as possible including the valve springs. I thought the Thumper the better choice of the two Comp' 'no springs required' cams available for my build. I'm sure there was a better choice out there elsewhere... But, that's now beside the point.

My problem:

The cam card for this cam is not correct. Also, the intake closing point was/is not listed on their website specs for this cam. The card states an intake closing event of 81 degrees ABDC?!

When I degreed the cam I was getting 66 degrees, which makes sense for a 'street' oriented cam. I am using a stock chain setup and it installed at 112 degrees. (the 2 degree advance could just be bad resolution from the small degree wheel) 66-2=64 degrees (see below)

I called COMP twice and two separate associates told me: 'The cam card is correct.'

Look: intake open + 180 degrees + intake close = duration (as long as all numbers are referenced at the same valve lift)

24+180+64=268 This IS the advertised duration @ .006" on the card.

If you do the math @ .050" you get 37 degrees Intake close. That also makes sense.

24+180+81=285? That duration isn't even listed on the card.

I am confident the cam will work fine because I trust the measurements I took when degreeing the cam. But, the fact they won't admit their numbers are possibly incorrect is driving me nuts!

Either the 81 degree intake closing event is wrong: (waaaay too late for a street cam)

Or, some other number(s) is/are incorrect.

I explained the the two 'experts' at COMP that I thought it was a typo, and they insisted once again it was correct. One of them also tried to tell me it was because 81 degrees was measured at .050"?!!

I then explained to him that I had based my build, including head gasket thickness, raised shift points, tire size, and gearing based on the power-band of this cam which I chose first, (and calculated the intake closing point before purchase) and I was concerned that if 81 degrees IC were correct, I would have no dynamic compression.

I was then told by the associate at COMP that I was "OVERTHINKING IT..."

I have since emailed COMPS 'cam selection experts' about the issue and have not received a response in over 14 days.

Does anything they told me make any sense?

PLEASE LOOK AT MY MATH and let me know if I messed something up.

I am getting the feeling if you buy from COMP CAMS you are probably on your own as far as legitimate technical help.

Please help and let me know your thoughts.

I apologize for the insane length of this. But, it's a long story.

I purchased and installed a Comp-Cams Thumper Cam. (112-700-11)

First, I know the Thumper probably has a little too much overlap for the single plane. But, the specs looked more attractive to me than the Comp-Cams Stage 1 NSR cam, It is a budget build and I was focused on reusing as much as possible including the valve springs. I thought the Thumper the better choice of the two Comp' 'no springs required' cams available for my build. I'm sure there was a better choice out there elsewhere... But, that's now beside the point.

My problem:

The cam card for this cam is not correct. Also, the intake closing point was/is not listed on their website specs for this cam. The card states an intake closing event of 81 degrees ABDC?!

When I degreed the cam I was getting 66 degrees, which makes sense for a 'street' oriented cam. I am using a stock chain setup and it installed at 112 degrees. (the 2 degree advance could just be bad resolution from the small degree wheel) 66-2=64 degrees (see below)

I called COMP twice and two separate associates told me: 'The cam card is correct.'

Look: intake open + 180 degrees + intake close = duration (as long as all numbers are referenced at the same valve lift)

24+180+64=268 This IS the advertised duration @ .006" on the card.

If you do the math @ .050" you get 37 degrees Intake close. That also makes sense.

24+180+81=285? That duration isn't even listed on the card.

I am confident the cam will work fine because I trust the measurements I took when degreeing the cam. But, the fact they won't admit their numbers are possibly incorrect is driving me nuts!

Either the 81 degree intake closing event is wrong: (waaaay too late for a street cam)

Or, some other number(s) is/are incorrect.

I explained the the two 'experts' at COMP that I thought it was a typo, and they insisted once again it was correct. One of them also tried to tell me it was because 81 degrees was measured at .050"?!!

I then explained to him that I had based my build, including head gasket thickness, raised shift points, tire size, and gearing based on the power-band of this cam which I chose first, (and calculated the intake closing point before purchase) and I was concerned that if 81 degrees IC were correct, I would have no dynamic compression.

I was then told by the associate at COMP that I was "OVERTHINKING IT..."

I have since emailed COMPS 'cam selection experts' about the issue and have not received a response in over 14 days.

Does anything they told me make any sense?

PLEASE LOOK AT MY MATH and let me know if I messed something up.

I am getting the feeling if you buy from COMP CAMS you are probably on your own as far as legitimate technical help.

Please help and let me know your thoughts.