I'm lining up my ducks to start my motor rebuild. I know the main bearings with the holes go in the block and the ones without go in the caps.

There are 2 cap bearing that are smooth with no holes, while the remaining 3 have no holes and grooves. These are King bearings I got from Summit in a box sealed in plastic. My question is in what order do they go?

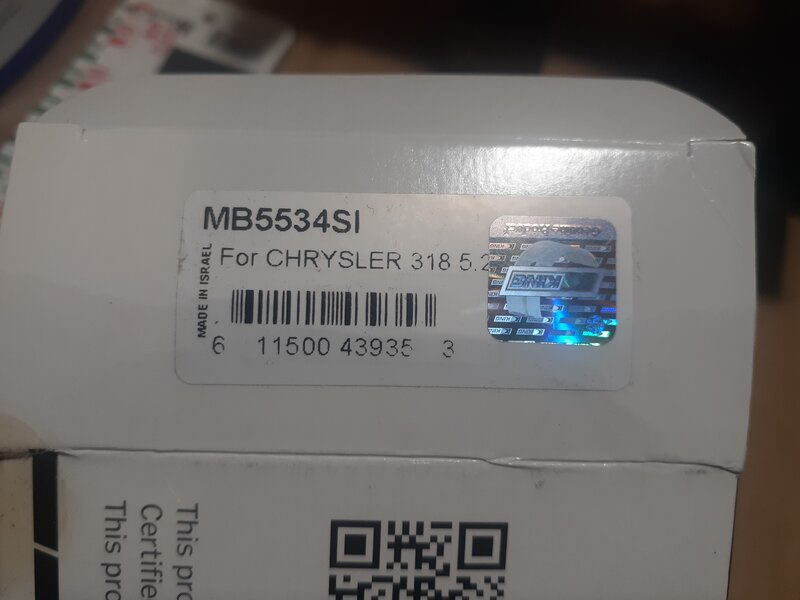

My photo illustrates an uneducated guess.

There are 2 cap bearing that are smooth with no holes, while the remaining 3 have no holes and grooves. These are King bearings I got from Summit in a box sealed in plastic. My question is in what order do they go?

My photo illustrates an uneducated guess.