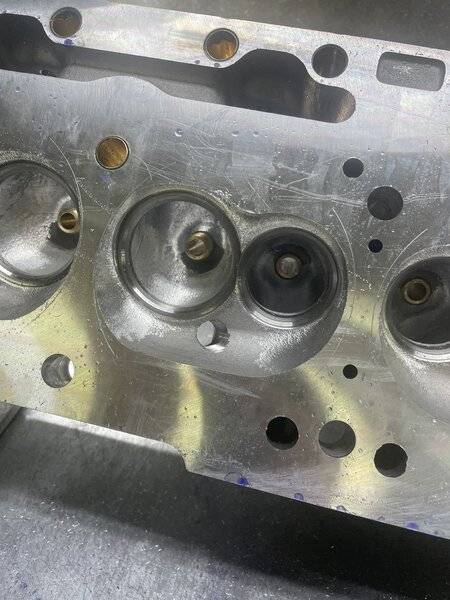

This time under my new rules so I have less work and the customer gets a better set of heads. I started drilling, honing, tubing, and porting Monday and put in a long day. Spent another 4-5 hours on it today and it should be getting a valve job for 2.055 Liberty Pro valves tomorrow. With predictions of rain this weekend again that means no racing AGAIN so I should have it on the flowbench this weekend after I get everything blended, sized, and final shaping.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pete, repeat. Another set of Speedmaster heads

- Thread starter pittsburghracer

- Start date

-

Pete is one lucky dude. Sometimes I wish I could be like Pete.

Pete is one lucky dude. Sometimes I wish I could be like Pete.

Still enjoying it buddy. I hope I never stop enjoying it.

will be interesting to see how those do, 1.58 or 1.60?

I always run a stock 1.60 valve size on speedmaster or Edelbrock heads. I can hit the port speed number I’m looking for. He is going with the 1.60 Liberty Pro series valve on the exhaust.

ahh ok, i wasn't sure what those came with, i think tf's are 1.58...I always run a stock 1.60 valve size on speedmaster or Edelbrock heads. I can hit the port speed number I’m looking for. He is going with the 1.60 Liberty Pro series valve on the exhaust.

I do have a quick question though.. is there a point where more cfm is useless.. Like me, if i'm honest how i drive i usually stay under 6k and not going to the track, is there a point where say 250cfm is as good as 300 if you don't go over X rpm? or perhaps even better under 6k with less cfm and more velocity? or.. too many variables. Just some thoughts i had earlier, not thinking of changing anything right now

ahh ok, i wasn't sure what those came with, i think tf's are 1.58...

I do have a quick question though.. is there a point where more cfm is useless.. Like me, if i'm honest how i drive i usually stay under 6k and not going to the track, is there a point where say 250cfm is as good as 300 if you don't go over X rpm? or perhaps even better under 6k with less cfm and more velocity? or.. too many variables. Just some thoughts i had earlier, not thinking of changing anything right now

For guys like you I first ask them what size cam they plan on running. If it’s a 484 purple shaft possibly get them checked out at go have fun. If you are going to run a .520 Racer Brown solid lifter cam then it’s your call. But I would recommend using the stock 2.02 valve and maybe a nice valve job and set your spring pressure. If you would rather have 290cfm instead of 250’s and are going to use the power then again it’s your choice. My customers if they want power usually spend the 100.00-200.00 more for a 2.055 valve. They usually ende up flowing 308-315cfm. For my customers they get a 5 angle valve job. With the stock 2.02 valve the throat size is already in the edge of being to big on the Speedmaster heads so the get a hand cut 70 and proper sizing of the 60-45-30 and a slight 15. A lot of shops will charge 350.00 for a valve job. It’s included in my porting charge. I should wise up and change that.

That's less than i expect for 2.055s.. thanks for the nfo.. and you should charge something for the valve job.. at least cover tool costs and suchFor guys like you I first ask them what size cam they plan on running. If it’s a 484 purple shaft possibly get them checked out at go have fun. If you are going to run a .520 Racer Brown solid lifter cam then it’s your call. But I would recommend using the stock 2.02 valve and maybe a nice valve job and set your spring pressure. If you would rather have 290cfm instead of 250’s and are going to use the power then again it’s your choice. My customers if they want power usually spend the 100.00-200.00 more for a 2.055 valve. They usually ende up flowing 308-315cfm. For my customers they get a 5 angle valve job. With the stock 2.02 valve the throat size is already in the edge of being to big on the Speedmaster heads so the get a hand cut 70 and proper sizing of the 60-45-30 and a slight 15. A lot of shops will charge 350.00 for a valve job. It’s included in my porting charge. I should wise up and change that.

Looking good HOSSThis time under my new rules so I have less work and the customer gets a better set of heads. I started drilling, honing, tubing, and porting Monday and put in a long day. Spent another 4-5 hours on it today and it should be getting a valve job for 2.055 Liberty Pro valves tomorrow. With predictions of rain this weekend again that means no racing AGAIN so I should have it on the flowbench this weekend after I get everything blended, sized, and final shaping.

View attachment 1716247848

View attachment 1716247849

View attachment 1716247850

View attachment 1716247851

View attachment 1716247852

-