Hello FABO!

I'm welding the axle tubes to the perches and i need some affirmation that in not forgetting something

to get the diff centered i can put a straight edge on the drum (with a couple of lugs to make sure its on) and measure from the fender and frame rail to make it even on both sides.

Right?

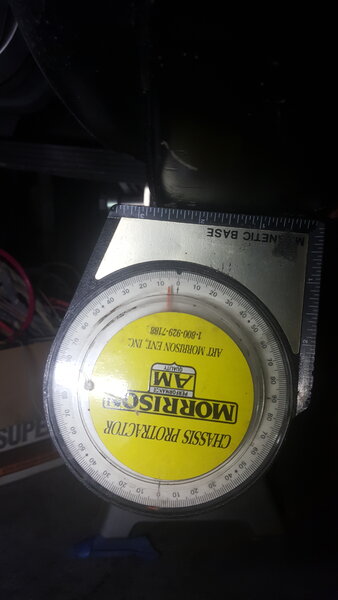

To get pinion.......uhhhhh, forgive me, i did use search option, but please double check me on this.

Pictures are from front to back.

Engine pan rail

Slip yoke

Driveline

Pinion yoke

Diff housing

What say you?

Welderup?

67 barracuda fastback 383 4speed 8 3/4.

I'm welding the axle tubes to the perches and i need some affirmation that in not forgetting something

to get the diff centered i can put a straight edge on the drum (with a couple of lugs to make sure its on) and measure from the fender and frame rail to make it even on both sides.

Right?

To get pinion.......uhhhhh, forgive me, i did use search option, but please double check me on this.

Pictures are from front to back.

Engine pan rail

Slip yoke

Driveline

Pinion yoke

Diff housing

What say you?

Welderup?

67 barracuda fastback 383 4speed 8 3/4.

Last edited:

Agreed.

Agreed.