You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ported Victor W2

- Thread starter mbaird

- Start date

-

How do the plug readings look and have you had to stagger jet the carburetor to clean it up? My first line of thought is that the runner dividers need trimmed back 90 degrees from the carburetor flange to the port floor. Look at the odd inverted triangular window from the center of the plenum to the outside runners. I may be wrong, but to me it just doesn't look like a happy flow path for the mixture to make it's way out of the plenum to the inside cylinders. Think about it plowing into the floor and then having to back up to make the turn around the runner divider.

How do the plug readings look and have you had to stagger jet the carburetor to clean it up? My first line of thought is that the runner dividers need trimmed back 90 degrees from the carburetor flange to the port floor. Look at the odd inverted triangular window from the center of the plenum to the outside runners. I may be wrong, but to me it just doesn't look like a happy flow path for the mixture to make it's way out of the plenum to the inside cylinders. Think about it plowing into the floor and then having to back up to make the turn around the runner divider.

Air flow can be very counter intuitive and I am no expert . So what I tried to do is open up the plenum without really changing the air path other than raising and rounding the top around the flange .

I was hoping @pittsburghracer would chime in

Well, admittedly I'm not either! But in this case, it's not just airflow, but mixture and charge distribution. I'm only going by the single plane manifold designs I've seen with the carburetor flange radiused to improve airflow. It usually follows the criteria if looking through the carburetor at WOT the runner divider will come close to intersecting the center of each diagonal sets of barrel, even if that means the dividers have to pushed back a little to establish that. Your plug readings may help determine some of what is happening. But yes, I would like to see his input here, too, as I believe he posted an article a while back on correcting the flow problems in a Super Victor.

Rat Bastid

Dunamis Metron

How do the plug readings look and have you had to stagger jet the carburetor to clean it up? My first line of thought is that the runner dividers need trimmed back 90 degrees from the carburetor flange to the port floor. Look at the odd inverted triangular window from the center of the plenum to the outside runners. I may be wrong, but to me it just doesn't look like a happy flow path for the mixture to make it's way out of the plenum to the inside cylinders. Think about it plowing into the floor and then having to back up to make the turn around the runner divider.

This is correct. You have to take the hook out of the divider. And thin them. Then you need to measure the port window at the flange and then measure the opening at the plenum and figure out how much taper you have.

Well, admittedly I'm not either! But in this case, it's not just airflow, but mixture and charge distribution. I'm only going by the single plane manifold designs I've with the carburetor flange radiused to improve airflow. It usually follows the criteria if looking through the carburetor at WOT the runner divider will come close to intersecting the center of each diagonal sets of barrel, even if that means the dividers have to pushed back a little to establish that. Your plug readings may help determine some of what is happening. But yes, I would like to see his input here, too, as I believe he posted an article a while back on correcting the flow problems in a Super Victor.

I am not doubting your input . Just being cautious in my attempt to improve my performance . And this is a street car so I dont want to sacrifice driveablity in an attempt to hit a HP number .

This is correct. You have to take the hook out of the divider. And thin them. Then you need to measure the port window at the flange and then measure the opening at the plenum and figure out how much taper you have.

Explain the "Hook in the divider"

And are you referring to sq area of plenum vs port exit ?

Rat Bastid

Dunamis Metron

Explain the "Hook in the divider"

And are you referring to sq area of plenum vs port exit ?

The shape of the opening of the runners is very important. It seems counterintuitive but looking at the number 5 and 6 runner openings you will see how the divider at the floor is hooking away from 7 and 8 and towards 5 and 6. You need to move the bottom of the divider out of the way. And shorten it up at the bottom. I would also lay the outside wall of 7 and 8 where they open into the plenum back some. You have to make sure you don’t break through there. Even if you do, it can be easily welded. I don’t remember how much materiel you have to work there. And yes on the area.

I was hoping @pittsburghracer would chime in

I really hate to comment on other people’s work. Mainly because lighting is so critical in seeing what is going on. No only my porting bench but my shop looks like an airport lit up at night. Close your eyes and run you fingers from the carb flange down each runner and down the vanes. Think radius while entering the runners. Would a short turn like a 90 degree turn (I don’t think so), thinned vanes but not sharp edged, no humps, divots, etc. the hardest thing about porting an intake manifold is getting it in the 36 different positions to get it right. I have V-blocks, different sized chunks of wood, and things to lean it against.

Rat Bastid

Dunamis Metron

I have a hard time putting what my eyes see into words, so let me see if I can explain it better. Where the 7 and 8 ports meet at the plenum, right there I would take that wall and lay it back.

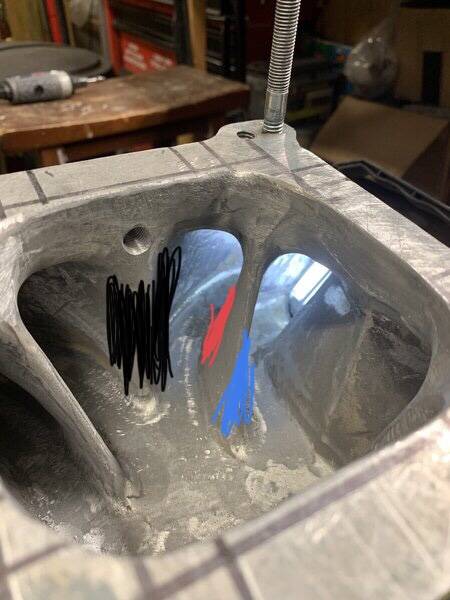

Maybe this will help. Where the black is, I would lay back until you get the opening bigger and get rid of some of that turn. If the end result is a very sharp point where the two ports come together, just put a radius on it. Where the red is I would go in there and pull that down and get that big hip out of that area. Where the blue is I would pull that back towards the number 7 port. I would start by grinding on that common wall between 5 and 7 on the 5 side and move that hook out. I hope that helps explain it a bit better.

Maybe this will help. Where the black is, I would lay back until you get the opening bigger and get rid of some of that turn. If the end result is a very sharp point where the two ports come together, just put a radius on it. Where the red is I would go in there and pull that down and get that big hip out of that area. Where the blue is I would pull that back towards the number 7 port. I would start by grinding on that common wall between 5 and 7 on the 5 side and move that hook out. I hope that helps explain it a bit better.

I really hate to comment on other people’s work. Mainly because lighting is so critical in seeing what is going on. No only my porting bench but my shop looks like an airport lit up at night. Close your eyes and run you fingers from the carb flange down each runner and down the vanes. Think radius while entering the runners. Would a short turn like a 90 degree turn (I don’t think so), thinned vanes but not sharp edged, no humps, divots, etc. the hardest thing about porting an intake manifold is getting it in the 36 different positions to get it right. I have V-blocks, different sized chunks of wood, and things to lean it against.

Ha ! That is exactly what I have done so far . Close my eyes and run my fingers thru the ports to sense the curvature . I have tried to stay away from the short side.

I have a hard time putting what my eyes see into words, so let me see if I can explain it better. Where the 7 and 8 ports meet at the plenum, right there I would take that wall and lay it back. View attachment 1715828950

Maybe this will help. Where the black is, I would lay back until you get the opening bigger and get rid of some of that turn. If the end result is a very sharp point where the two ports come together, just put a radius on it. Where the red is I would go in there and pull that down and get that big hip out of that area. Where the blue is I would pull that back towards the number 7 port. I would start by grinding on that common wall between 5 and 7 on the 5 side and move that hook out. I hope that helps explain it a bit better.

That clarifies everything . Thx

Just to confirm on the area, I take it that you’re measuring the area of each runner entry in order to equalize the runners entry points as much possible. The more I work with porting the more it reminds me of making knives by hand on a slack belt grinder. You have think about every single action and every movement all the time. In other words, IT’S HARD!The shape of the opening of the runners is very important. It seems counterintuitive but looking at the number 5 and 6 runner openings you will see how the divider at the floor is hooking away from 7 and 8 and towards 5 and 6. You need to move the bottom of the divider out of the way. And shorten it up at the bottom. I would also lay the outside wall of 7 and 8 where they open into the plenum back some. You have to make sure you don’t break through there. Even if you do, it can be easily welded. I don’t remember how much materiel you have to work there. And yes on the area.

Just to confirm on the area, I take it that you’re measuring the area of each runner entry in order to equalize the runners entry points as much possible. The more I work with porting the more it reminds me of making knives by hand on a slack belt grinder. You have think about every single action and every movement all the time. In other words, IT’S HARD!

Yeah ... I am measuring it with my fingers . Like a shot of whiskey ! Lol

You give me way too much credit !

Two thumbs and eight fingers, each is a unique measuring tool. Start fingering (not trying to be cute) and you can feel how tight or loose things are at various points on them.Honestly its not possible to get calipers in to measure width .

Rmoore

Well-Known Member

I have a hard time putting what my eyes see into words, so let me see if I can explain it better. Where the 7 and 8 ports meet at the plenum, right there I would take that wall and lay it back. View attachment 1715828950

Maybe this will help. Where the black is, I would lay back until you get the opening bigger and get rid of some of that turn. If the end result is a very sharp point where the two ports come together, just put a radius on it. Where the red is I would go in there and pull that down and get that big hip out of that area. Where the blue is I would pull that back towards the number 7 port. I would start by grinding on that common wall between 5 and 7 on the 5 side and move that hook out. I hope that helps explain it a bit better.

Thank you for that ! That looks like it makes sense !! Or makes sense to me anyway !

View attachment 1715828966 You can use an inside calipers to measure in your intake manifold, setting it to or measuring it with a scale(ruler). This is how my grandpa who was a pattern maker made patterns measuring with a shrink rule.

Like I have a pair of those ....

Wait a minute ...I do ! Lol

You could also scribe depths into the head port side,but only so far with a depth scriber like this to compare caliper sizes from port to port.

An old circle track magazine tech article on manifold and head porting showed blocking each runner and pouring Perma-Flex silithane or blu-sil into each runner entry. They let it set up and marked all the around it every half inch of length to use the dimensions as a measuring guide to equalize the port dimensions. That would be crazy expensive with the current cost of moldable rubber or silicone (I don't guess the NASCAR teams gave two s***s at that time) but you may be able to use modeling clay to the same end for a cheaper alternative. You may have to rub the runner opening to about four inches in down with paraffin beforehand, but it may be a good way to final check how close you are with everything once you get done grinding while using the outside calipers.

Also consider making templates out of stiff construction paper with a scissors and matching port shapes at certain depths. But you know this might NOT get equal flow to all cylinders, that takes a flow bench, popsicle sticks and a die grinder creating troughs and dams then verifying on a dyno. A lot of work and money. Thats how pro stock racers make stupid power with race gasoline with a carburetor, its mostly in the intake manifold and how it works with the rest of the combination.

-