rich006

Learning as I go

This thread will document my first attempt at rust repair, on my '74 Swinger quarters and rocker panel. The paint is original except for some touchup that was done by previous owner. I'm not going for a concours restoration, just trying to stop the rot, preserve as much original good metal as possible, and make the car presentable as a daily driver. I don't want to do any welding, and I'm not too proud to fill some holes with plastic filler.

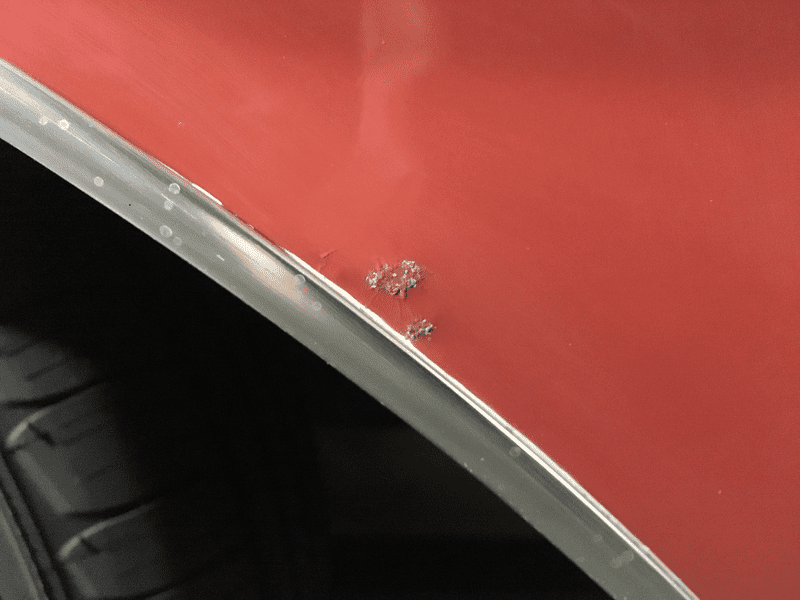

Here's the left quarter

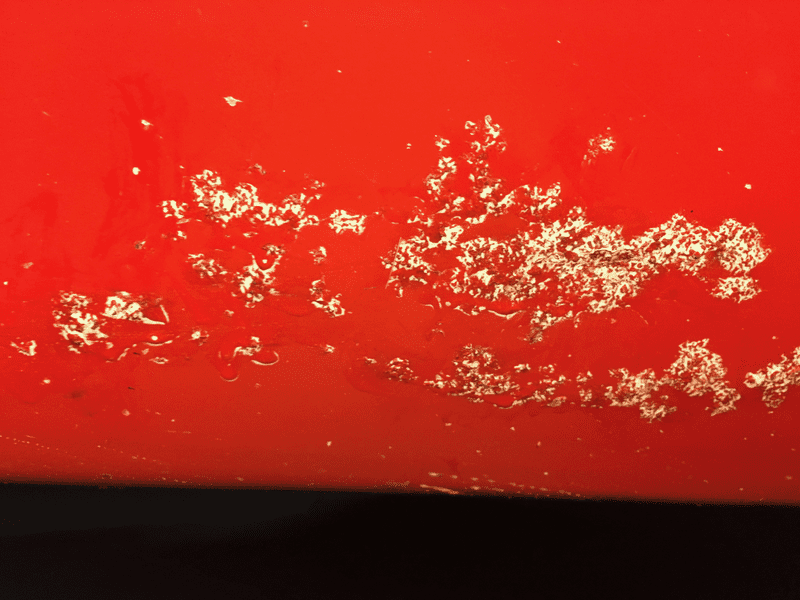

and a close-up

the right quarter

a close-up of the lower right quarter

The worst of it is just behind the wheel.

Here's the left quarter

and a close-up

the right quarter

a close-up of the lower right quarter

The worst of it is just behind the wheel.