Been working on this port for 5-6 months now as time allows. The objective is primarily to learn, so I take liberties with epoxy and clay that would not work at all in a running engine. My goal is this - to find the flow limits of a 2.02 valve and to learn why flow increases stop. After all, a 2.02 valve is theoretically capable of 375 cfm or more, so why does the 2.02 valve in a wedge head only hit the low 300s?

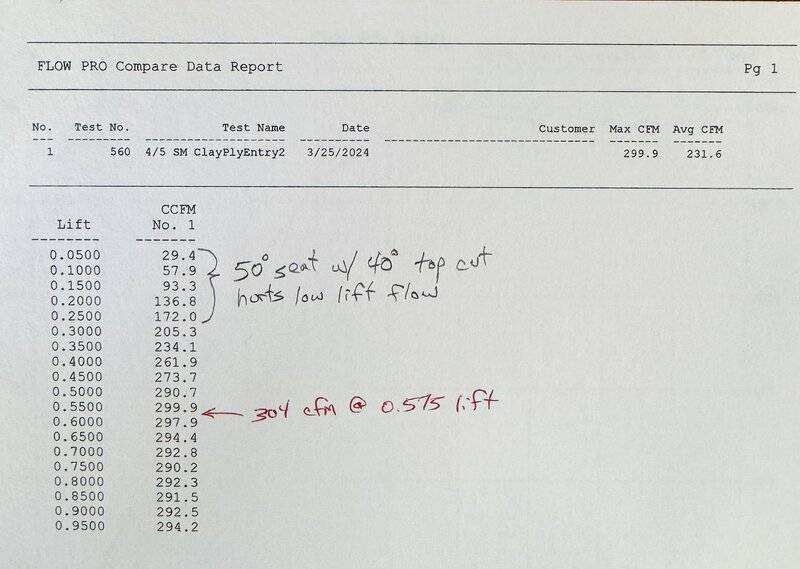

Some pictures of a recent port mold are attached along with some recent flow numbers. Currently, the port peaks at 304 cfm. I think there is at least another 5-10 cfm to be found. There are a few areas in the port to clean up (bulges marked A and D). The throat is currently at 88.2% wide and 89.2% deep, so it can be worked on a little. Valve job is 40/50/65/75/80 with valves sunk to achieve a wide top cut. I’m still not happy with the short turn, but it’s the best I’ve had so far.

This is nothing new for you experienced guys, but it’s new to me and may help some of the less experienced readers which is why I share. In my testing/probing/reading/learning, I think the single thing that stops flow gains in this port (on a flow bench) is flow separation. High speed air needs containment or boundaries for efficient flow. The walls of the port, the valve itself and the surfaces in the combustion chamber provide these boundaries. A port must twist and turn between pushrods and head bolts then quickly make a almost 90 degree turn into the chamber. In the chamber, the walls (flow boundaries) disappear and the air quickly expands and slows down. It is the combination of twists and turns (port shape), velocity (due to available area) and the fast expansion in the chamber that present the problems.

It all leads to this - flow separation from surfaces due to uncontrolled divergence (increase in area). Air does not like to slow down quickly or change direction quickly. It especially does not like to make a turn and diverge at the same time. So this means that increasing the flow area through a turn is a recipe for flow separation. This is exactly what happens in the SBM port over the short turn. There is not enough (usable) area at the apex of the short turn, so the port is still expanding through part of the turn. The usable area at the apex is dictated by the head bolt on one side and by the pushrod pinch on the other side. To prevent flow separation, there is a limit to the angle of divergence after the PRP.

This diverging angle plus the location of the head bolt set the port width at the apex. Trying to increase the width beyond these points (my bulges A and D) does not help. In fact, it can decrease flow by causing localized areas of flow separation.

So here’s one of my primary learnings so far. In seeking max flow from the SBM head, the ultimate challenge is to manipulate the controlling surfaces (port walls, chamber walls, seat angles, valve angles) in such a way as to prevent the flow from separating from these surfaces as much as possible and to create an efficient flow into the chamber. Flow separation shuts down (reduces) the available flow area which ultimately reduces flow.

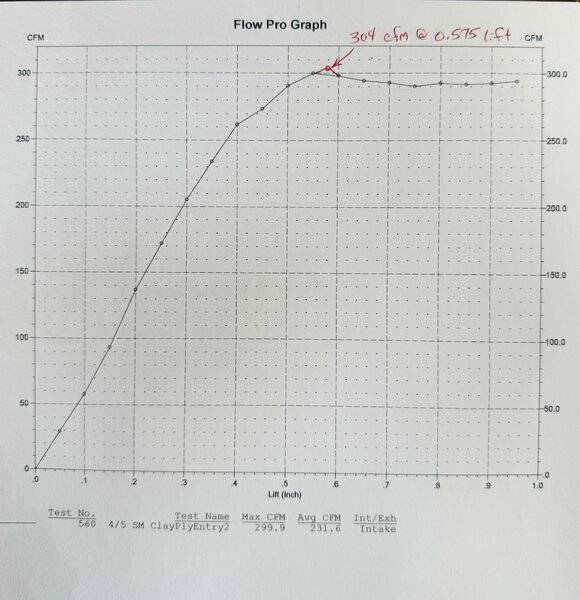

One more quick observation that I’m trying to understand. Look at the flow graph (not the table) at 0.400 lift. This is the point where my port starts having some issues. Two things are happening at this point. One, from pitot probing of the valve perimeter from the chamber side, I know that this is the lift point where the flow starts to separate from the short side. Secondly, at 0.400 lift the valve curtain area is equal to the pushrod pinch area. So this means that after 0.400 lift, the PRP is the area ‘choke’ point.

Some pictures of a recent port mold are attached along with some recent flow numbers. Currently, the port peaks at 304 cfm. I think there is at least another 5-10 cfm to be found. There are a few areas in the port to clean up (bulges marked A and D). The throat is currently at 88.2% wide and 89.2% deep, so it can be worked on a little. Valve job is 40/50/65/75/80 with valves sunk to achieve a wide top cut. I’m still not happy with the short turn, but it’s the best I’ve had so far.

This is nothing new for you experienced guys, but it’s new to me and may help some of the less experienced readers which is why I share. In my testing/probing/reading/learning, I think the single thing that stops flow gains in this port (on a flow bench) is flow separation. High speed air needs containment or boundaries for efficient flow. The walls of the port, the valve itself and the surfaces in the combustion chamber provide these boundaries. A port must twist and turn between pushrods and head bolts then quickly make a almost 90 degree turn into the chamber. In the chamber, the walls (flow boundaries) disappear and the air quickly expands and slows down. It is the combination of twists and turns (port shape), velocity (due to available area) and the fast expansion in the chamber that present the problems.

It all leads to this - flow separation from surfaces due to uncontrolled divergence (increase in area). Air does not like to slow down quickly or change direction quickly. It especially does not like to make a turn and diverge at the same time. So this means that increasing the flow area through a turn is a recipe for flow separation. This is exactly what happens in the SBM port over the short turn. There is not enough (usable) area at the apex of the short turn, so the port is still expanding through part of the turn. The usable area at the apex is dictated by the head bolt on one side and by the pushrod pinch on the other side. To prevent flow separation, there is a limit to the angle of divergence after the PRP.

This diverging angle plus the location of the head bolt set the port width at the apex. Trying to increase the width beyond these points (my bulges A and D) does not help. In fact, it can decrease flow by causing localized areas of flow separation.

So here’s one of my primary learnings so far. In seeking max flow from the SBM head, the ultimate challenge is to manipulate the controlling surfaces (port walls, chamber walls, seat angles, valve angles) in such a way as to prevent the flow from separating from these surfaces as much as possible and to create an efficient flow into the chamber. Flow separation shuts down (reduces) the available flow area which ultimately reduces flow.

One more quick observation that I’m trying to understand. Look at the flow graph (not the table) at 0.400 lift. This is the point where my port starts having some issues. Two things are happening at this point. One, from pitot probing of the valve perimeter from the chamber side, I know that this is the lift point where the flow starts to separate from the short side. Secondly, at 0.400 lift the valve curtain area is equal to the pushrod pinch area. So this means that after 0.400 lift, the PRP is the area ‘choke’ point.