moparmat2000

Well-Known Member

Hi Y'all

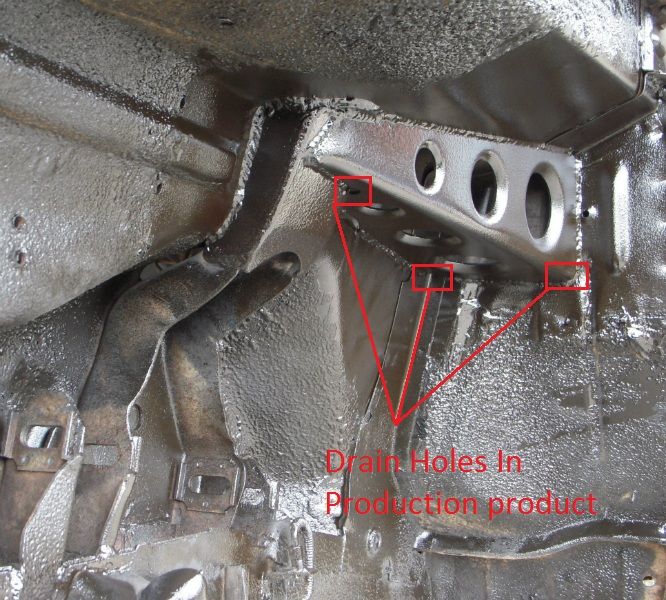

Im getting to the point on my build up that i want to start stiffening up the frame at all the points it flexes at. Already well along with a 2x3 subframe connector install. Thinking of buying the torque box plates front and rear from us car tool. Or fabricating these cheaper myself. I also ground down the crappy welds on my k frame, bolted it in place and rewelded it. And seam welded it all the way around, i also fitted and welded an 1/8" stiffening plate to the bottom center to stiffen up the K frame.

Anybody make a stiffening bar to weld to the front frame horns to tie them together . The lower half of my rad support is bent, was thinking of cutting it off and replacing it with a tubular support anyways.

Anybody make anything to stiffen up the upper A arm mounting areas to prevent or lessen flex in these areas.

Please let me know.

Matt

Im getting to the point on my build up that i want to start stiffening up the frame at all the points it flexes at. Already well along with a 2x3 subframe connector install. Thinking of buying the torque box plates front and rear from us car tool. Or fabricating these cheaper myself. I also ground down the crappy welds on my k frame, bolted it in place and rewelded it. And seam welded it all the way around, i also fitted and welded an 1/8" stiffening plate to the bottom center to stiffen up the K frame.

Anybody make a stiffening bar to weld to the front frame horns to tie them together . The lower half of my rad support is bent, was thinking of cutting it off and replacing it with a tubular support anyways.

Anybody make anything to stiffen up the upper A arm mounting areas to prevent or lessen flex in these areas.

Please let me know.

Matt