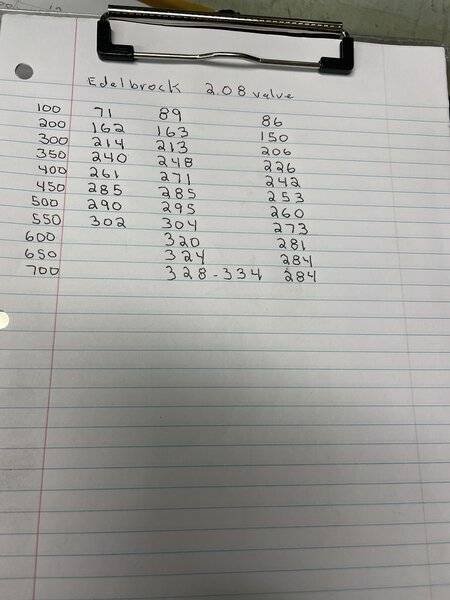

Sure it would still run good but are willing to pay good money for good heads only to lose 60 horsepower or more. I’m not. Here’s some before porting numbers and pictures. Got this intake yesterday and started working on it today. Far right column is with intake bolted on.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This is why if you port your heads, port your intake

- Thread starter pittsburghracer

- Start date

-

fratzog lover

Well-Known Member

Wow. Yeah, those ports can use a little tweaking.

LocuMob

Fluid Technician

A lot of meat left on them bones.

Look at the difference between .450 and .500 lift. Wow!

4 runners roughed in and I’ll probably get two more done before I call it a night. 8:30PM target quitting time.

LocuMob

Fluid Technician

Pm me your address, I'll send my heads and intake to you!4 runners roughed in and I’ll probably get two more done before I call it a night. 8:30PM target quitting time.

View attachment 1716013916

View attachment 1716013917

View attachment 1716013918

Yeah really. Do you do slant 6 heads? LOL

Well thanks to Rat Bastid and turning us onto Killer Carbide burrs I got all 8 roughed in by 8:30. These burrs kick butt and are a major time saver. I did 95% of this work tonight with a 1/2 single cut burr and I used to HATE single cut burrs. I Dont know how to tag him but if he sees this thank you Sir. I will be placing another order for some 3/8 headed burrs soon.

I just looked up the burrs. I assume they don't pack up with aluminum like regular burrs?

I just looked up the burrs. I assume they don't pack up with aluminum like regular burrs?

I think rat and I both did a post on these burrs. The company owner hand cuts them and joined in on the post. I still dip them to cool them but never had one even start to clog.

I just looked up the burrs. I assume they don't pack up with aluminum like regular burrs?

Killer Carbide Review UPDATE WITH VIDEO

Nice, looks like you bought two single cuts and some double cut ones also. How do the double cut ones work? They look a lot like what I was using.

Nice, looks like you bought two single cuts and some double cut ones also. How do the double cut ones work? They look a lot like what I was using.

They work great but I’ve been punishing this burr. At least four heads, this intake, and a few other projects.

What are the flow #s now with openings ported?

I wish I could take time to clean it up and flow test it for you guys but I gotta get it finished. I’ll retest it when it’s finished

360duster

Well-Known Member

thanks for the info John! if possible please show us the plenum work you do with this specific intake....wanna learn and repeat ;-)

Michael

Michael

More rough in work today guys, this time plenum work. All done with the same 1/2 inch single cut burr. Tomorrow I’ll bolt the supplied one inch spacer and rough it in then it’s double cut burr time to blend everything together and finish it off. Probably won’t work long tomorrow if there’s a good football game on but I really have to have it done by Saturday morning. Valves should be here to finish off a customers Speedmaster heads and he’s been very very patient.

Rat Bastid

Dunamis Metron

Greg’s burrs are absolutely second to none. IMO his burrs put everything else to shame, and I’ve used tons of different burrs over the years.

Its staggering to think of how many burrs get used every year if you add up just the guys here on FABO who do porting on regular basis.

Killer Carbides is the perfect name for his burrs. Not only are they very sexy, they flat work better than every other burr I tried.

And they cut easier and cleaner than everything else too.

I‘ve got a single coming up and I’m actually looking forward to porting it with those burrs. And then testing the port work on the dyno.

I‘m excited.

Its staggering to think of how many burrs get used every year if you add up just the guys here on FABO who do porting on regular basis.

Killer Carbides is the perfect name for his burrs. Not only are they very sexy, they flat work better than every other burr I tried.

And they cut easier and cleaner than everything else too.

I‘ve got a single coming up and I’m actually looking forward to porting it with those burrs. And then testing the port work on the dyno.

I‘m excited.

I wonder what would happen, if instead of grinding material off of the manifold to match the head at the “pinch”, we filled in the head to make that a straighter shot.

Rat Bastid

Dunamis Metron

I wonder what would happen, if instead of grinding material off of the manifold to match the head at the “pinch”, we filled in the head to make that a straighter shot.

Look at the W2 head. They moved the pushrod and made the port wider at the pinch.

Air HATES changes in shape and corners.

Ya, that’s what I’m saying. Go ahead and grind the pinch but it’s still there. It will be smaller at the entrance but no change in shape.Look at the W2 head. They moved the pushrod and made the port wider at the pinch.

Air HATES changes in shape and corners.

Dan the man

Well-Known Member

How far into the ports do you go?

How far into the ports do you go?

On the Victor340 I can hit about everything working it from both ends. One of the hardest things about porting an intake is blocking it in every position needed to port it right. Lots of turning and blocking. Your hands take a beating because everytime any piece of the six inch burr hits anything it jumps. And your back take a beating leaning to see what you have to see.

-