Ok checked with key on run from the positive post to where the blue wire attaches to alternator and got 1.5 volts. Next I tried the blue wire from voltage regulator to positive post and got the same voltage of 1.5 volts. Next I tried by unplugging the voltage regulator. I got .3 volts from positive post to blue wire on alternator. Next tried from positive post to the blue wire on the pigtail that goes in voltage regulator and got .3 volts. Any ideas? Getting around 15.25-16.00 volts at battery at idle

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Voltage regulator overcharging

- Thread starter Phil21502

- Start date

-

Were all our tests with the engine running?

TrailBeast

AKA Mopars4us on Youtube

Ok checked with key on run from the positive post to where the blue wire attaches to alternator and got 1.5 volts. Next I tried the blue wire from voltage regulator to positive post and got the same voltage of 1.5 volts. Next I tried by unplugging the voltage regulator. I got .3 volts from positive post to blue wire on alternator. Next tried from positive post to the blue wire on the pigtail that goes in voltage regulator and got .3 volts. Any ideas? Getting around 15.25-16.00 volts at battery at idle

That blue wire is tied into other parts of the harness via the crimp weld, so it doesn't surprise me that you get what could be considered strange readings.

Start by making sure the regulator is grounded really well, and if your car has the connector behind the passenger side cylinder head, clean the terminals for that blue wire there also.

Most likely what is happening is the your blue wire is telling the regulator that the voltage is too low and the regulator is trying to make up for it by charging more.

Once the regulator is able to see the actual system voltage without loss from bad or dirty connections your charging voltage may stabilize where it should be.

Some of us have moved that blue wire off the harness and connected it to the starter relay battery post with an ignition activated relay to alleviate issue's like that, so the regulator sees more accurate battery voltage.

A good positive ground for your regulator is the best place to start.

What do you get while it is running on the same wires?at regulator and alternator were done with key in run position

I’ll check that tomorrow. Need to to put new heater hoses on it. This thing is killing me. Lol. Also with key in run position I’m getting 10.45 volts from the battery neg post to the blue run wire at the regulator.

Last edited:

Mattax

Just the facts, ma'am

When everything is off, voltage from ground to battery positive is battery voltage.

When the engine is running, voltage at the battery positive is alternator output voltage, minus any drops due to resistance in flow. In any event, its not battery voltage.

If the key is in the run position, and the blue wire is less than 14.2 V, the voltage regulator will allow current through the alternator's field.

Blue wire is the regulator voltage 'sensing'

Blue wire supplies power to the alternator's field.

Green wire is the alternator field's ground. The regulator contains the 'switch' that allows the ground circuit to complete unrestricted, not all all, or something in between depending on the voltage in the blue wire.

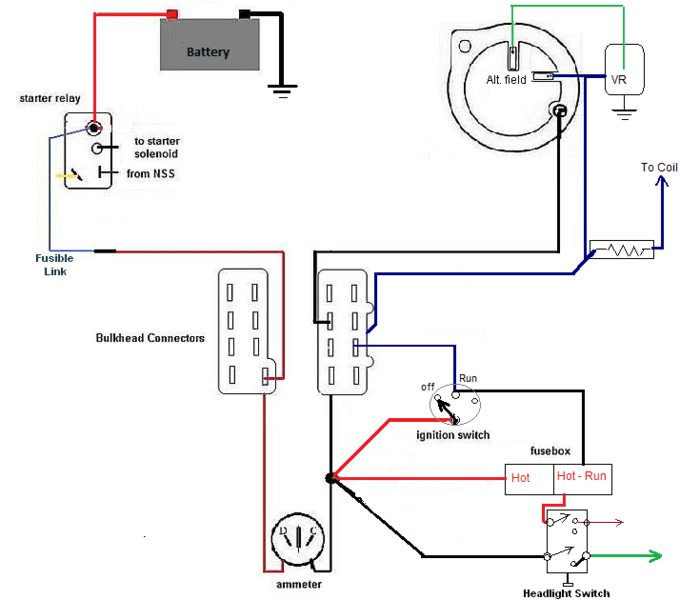

A couple diagrams here that may help..

When the engine is running, voltage at the battery positive is alternator output voltage, minus any drops due to resistance in flow. In any event, its not battery voltage.

If the key is in the run position, and the blue wire is less than 14.2 V, the voltage regulator will allow current through the alternator's field.

Blue wire is the regulator voltage 'sensing'

Blue wire supplies power to the alternator's field.

Green wire is the alternator field's ground. The regulator contains the 'switch' that allows the ground circuit to complete unrestricted, not all all, or something in between depending on the voltage in the blue wire.

A couple diagrams here that may help..

Do you have a good engine to frame ground

You could use a piece of wire with say a 10 amp fuse connect it directly between battery positive & Alternator blue terminal the charging voltage should drop to normal voltage if it does not then either the regulator has a bad ground connect try a piece of wire directly from the regulator frame to the negative battery terminal if the voltage is still high it could be a bad regulator

Also when you have the blue wire from the positive to the regulator you will not be able to turn the engine off at the key as it will also feed the coil circuit.

You could use a piece of wire with say a 10 amp fuse connect it directly between battery positive & Alternator blue terminal the charging voltage should drop to normal voltage if it does not then either the regulator has a bad ground connect try a piece of wire directly from the regulator frame to the negative battery terminal if the voltage is still high it could be a bad regulator

Also when you have the blue wire from the positive to the regulator you will not be able to turn the engine off at the key as it will also feed the coil circuit.

Mattax

Just the facts, ma'am

Here's a couple more filled in as examples:

The voltage of 12.8 is just an example of a fully charged, good battery and switch off. Yours might be a little more or a little less. The point is voltage everywhere should be the same when there is no current flow. Resistance doesn't matter because there is no flow.

Next is an example of Switch in Run, Engine Off.

Randomly choosing 12.1 as the battery voltage.

There is 2 or 3 amps of current flowing. Dashed arrows represent the flow.

Most is to, and through, the alternator field. The coil will draw current until its saturated and then zero. If there is an electronic ignition, that too will draw current with the switch on, but this is a points example.

Small voltage drops represent resistance through the wires and connections that current flows through.

The big drop in voltage will be through the field windings. The voltage on the second terminal will be something closer to zero. The exact amount will depend on the regulator. If the regulator allows full current flow because it senses the system voltage is very low, then voltage in the green wire will be close to ground.

The voltage of 12.8 is just an example of a fully charged, good battery and switch off. Yours might be a little more or a little less. The point is voltage everywhere should be the same when there is no current flow. Resistance doesn't matter because there is no flow.

Next is an example of Switch in Run, Engine Off.

Randomly choosing 12.1 as the battery voltage.

There is 2 or 3 amps of current flowing. Dashed arrows represent the flow.

Most is to, and through, the alternator field. The coil will draw current until its saturated and then zero. If there is an electronic ignition, that too will draw current with the switch on, but this is a points example.

Small voltage drops represent resistance through the wires and connections that current flows through.

The big drop in voltage will be through the field windings. The voltage on the second terminal will be something closer to zero. The exact amount will depend on the regulator. If the regulator allows full current flow because it senses the system voltage is very low, then voltage in the green wire will be close to ground.

Last edited:

I’ll check that tomorrow. Need to to put new heater hoses on it. This thing is killing me. Lol. Also with key in run position I’m getting 10.45 volts from the battery neg post to the blue run wire at the regulator.

'Mornin'........This reading is really just another way of measuring the 1.5V drop you found in your first post. Don't make this hard. You need to check the SUPPLY PATH from the battery to the blue regulator wire. If you have factory unmodified wiring this is generally.......

battery............fuse link...........through the bulkhead connector on the big RED, to the ammeter.........through the ammeter.........out on the big BLACK...........to the under dash WELDED SPLICE...........off to the ignition switch CONNECTOR.................through the switch...............out the connector on the BLUE............back out through the bulkhead through the BLUE..............(and last).........whatever "in harness" splice branches the blue off to what it feeds, depending on the year

"Rig" your self a long clip lead out of anything from no22 to no 16 or better so you can hook one meter lead to either battery neg or pos and get to the under-dash and other areas

"Chase" the path...........most likely the drop (can be more than one)

the RED wire connection at the bulkhead......

the AMMETER connections and connectors

the AMMETER itself

in rare cases the WELDED SPLICE

the IGNITION SWITCH CONNECTOR

the IGNITION SWITCH itself

the BLUE bulkhead connector

any other crimps/ terminals and or harness splices in the path

READ the MAD article........even if you don't do that mod, the article describes how this happens, and has a great simplified diagram

If you "don't" have, then go to MyMopar and download a service manual/ wiring diagram

Ok so traded some wires and found the voltage drop point. Where all the blue wires splice together is 12.5. Go over to where this blue wire is in a connector that leads to the choke and voltage regulator and I’m getting 12.5 with the connector unplugged. Now with it plugged in I’m only getting the 10.8ish volts on the other side of connector. Here’s a pic of locations.

Mattax

Just the facts, ma'am

In your first check, with the wires to the voltage regulator disconnected, there's no flow. Without flow, there's no voltage drop.

With the regulator connected, recheck the 10.8 Volts and then measure the next accessible spot (the splice pictured?).

If that next location back is 12. something, then the problem is in the connector.

If the next location back is also 10.8 Volts, then keep working back along the wire to the next accessible location. Repeat until you find a huge drop or lots of smaller but measurable drops.

With the regulator connected, recheck the 10.8 Volts and then measure the next accessible spot (the splice pictured?).

If that next location back is 12. something, then the problem is in the connector.

If the next location back is also 10.8 Volts, then keep working back along the wire to the next accessible location. Repeat until you find a huge drop or lots of smaller but measurable drops.

Sorry I worded it wrong. I’m getting 12.5 at splice and followed the wire going to the choke. Right before the choke is that plastic connector. It’s getting 12.5 at it but coming out the back it’s only 10.8. So it has to be in this connector. Not much to it tho I would think to mess up?

Mattax

Just the facts, ma'am

OK. You've got it.Sorry I worded it wrong. I’m getting 12.5 at splice and followed the wire going to the choke. Right before the choke is that plastic connector. It’s getting 12.5 at it but coming out the back it’s only 10.8. So it has to be in this connector. Not much to it tho I would think to mess up?

Yup, there's not much too it but lots of stuff happens that can make a poor connection - and once it starts it getting resistance, it runs hotter and damage gets worse.

When you look in the connector, you probably see something. If not immediately, then when you pop out the terminals.

Sometimes the copper strands get stressed or broken by someone yanking on the cable by accident during a repair. Most common is some sort of oxidation on the terminals or even the copper wire. I've have two poor connections on my Wagoneer from terminals sliding a little bit back out of the plastic connector as they were pushed into place. One was on the Ford style coil C-connector, and the other on the GM style alternator connector. Both were hard problems to identify because they were still making connection, but not good ones and locked in. So you never know.

MoparLeo

NRA BENEFACTOR LEVEL LIFE MEMBER

Mattax

Just the facts, ma'am

That's so irrelevant.

If he needs to buy anything, he'll need a terminal release tool, a good crimper, and whatever type terminals are in that connector.

If its just some heavy oxidation, might get away with a good cleaning.

Here's a good list of different types of terminals & connectors.

Our Mopars mostly use a variation of the Packard 56 type.

Automotive Electrical Connectors

Some other types were used too. We'll know soon enough what this connector has.

Aftermarket Packard 56 style female terminal on left. Typical Chrysler type on right.

Middle is similar aftermarket to Chrysler type, but not quite same.

If he needs to buy anything, he'll need a terminal release tool, a good crimper, and whatever type terminals are in that connector.

If its just some heavy oxidation, might get away with a good cleaning.

Here's a good list of different types of terminals & connectors.

Our Mopars mostly use a variation of the Packard 56 type.

Automotive Electrical Connectors

Some other types were used too. We'll know soon enough what this connector has.

Aftermarket Packard 56 style female terminal on left. Typical Chrysler type on right.

Middle is similar aftermarket to Chrysler type, but not quite same.

Last edited:

Mattax

Just the facts, ma'am

IMO, only if you're desperate. Connectors are awful handy. Most butt connectors are only so-so, especially in that environment. If I have to use any single crimp insulated connectors, I try to use marine type.Gonna try a spray cleaner first. What about cutting the wire off the connector and using a butt connector to connect them together?

The factory types shown above are called 'open barrel connectors'. They have two double crimps. IMO that's a better grip and surface area. The second crimp grabs the insulation and helps create some strain relief.

I'd also first see what is wrong. Is it just that circuit, or all the circuits in that connector. Take the terminals out. If the terminals look like the ones above, the flat lock tab can be released with a flattened cotter pin, tiny screw driver or similar. Push the terminal out the back while the pin is keeping the tab depressed.

Quick dry cleaner is good, butf most likely will need some scrubbing too.

-

Similar threads

- Replies

- 3

- Views

- 412