Got a few things knocked out this week. Radiator is in, upper hose in an 06 Charger RT hose. The lower I purchased didn't work. I think a hose with a 45 degree angle will work. They seem to be a fairly common universal hose. I trimmed the heater hoses up and they laid out nice and neat. My AC lines previously went through the fender apron where the heater hoses are, but that isn't going to work. I'll block those holes off and run them behind the bumper. I had a friend help me stab the trans, but I still need to connect everything to it. I also received the quadspark modules from DIY Autotune for the "dumb" stock coils. Installing those will likely be a time consuming task since I plan to mount them behind the dash board. This will likely be the only real wiring change from my previous efi setup.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hemi Swapping a perfectly good 70 Duster

- Thread starter racerjoe

- Start date

-

Looking very sanitary!! Attention to details, that's where it's at.Banging out the little things with plenty more to go. Manifold should be on for good, so why not take some photos!

View attachment 1716252143

View attachment 1716252144

Thanks! I think its going to end up being a cleaner look than the LA engine. Having the accessories mounted low help with that.Looking very sanitary!! Attention to details, that's where it's at.

Thanks! I also hate the appearance of worm drive hose clamps. On the LA engine, I had put heat shrink on them and painted them black to mask the ugly.Locking great Brutha! Have you tried the Gates heat shrink hose clamps? I used them on my heater hoses for a clean look. I like using them on Rad hose splices too, when I can.

I've never used them, but that's what I intend to use on the heater hoses since both ends have a threaded fitting for removal.

I'm going to use t-bolt clamps for the radiator hoses. I just need to be careful tightening those because they will crush the aluminum inlet/outlet on the radiator if overtightened.

I used the Gates 32925 for the heater hoses.. 15/16 - 1-1/16. Th only thing I don't care for is the white printing on them. I suppose I could mask it with somethingThanks! I also hate the appearance of worm drive hose clamps. On the LA engine, I had put heat shrink on them and painted them black to mask the ugly.

I've never used them, but that's what I intend to use on the heater hoses since both ends have a threaded fitting for removal.

I'm going to use t-bolt clamps for the radiator hoses. I just need to be careful tightening those because they will crush the aluminum inlet/outlet on the radiator if overtightened.

Grainger was the cheapest place, ironically. I have free shipping with them, so I saved a few bucks

Not much time on the car over the weekend but managed to knock out a few things.

"Cold air intake" adds 25HP, right? This will be painted with Cerakote to match the rest of the black engine parts after I weld my IAC bung and a bracket on it.

PS tank and overflow are painted and I had to make a new steel overflow line to the radiator overflow since this radiator has the cap on the opposite side.

The last two time consuming projects are exhaust and installation of the coil ignitor wiring. Getting close!

"Cold air intake" adds 25HP, right? This will be painted with Cerakote to match the rest of the black engine parts after I weld my IAC bung and a bracket on it.

PS tank and overflow are painted and I had to make a new steel overflow line to the radiator overflow since this radiator has the cap on the opposite side.

The last two time consuming projects are exhaust and installation of the coil ignitor wiring. Getting close!

Ended up getting the coil drivers installed last night. It wasn't as time consuming as I thought it would be. Taking the seat out helped make work under the dash easier.

For those not knowing or understanding why I needed to install coil drivers, I thought I'd explain it. I was previously running LS style coils. LS coils are considered "smart" coils, meaning they have their own driver inside them. There are 4 wires for each coil. Power, engine block ground, ECU signal ground, and ECU logic signal to fire the coil. The logic signal from the ECU is 5VDC based upon duty cycle.

The Hemi coil is only 2 wires. Just like your old school canister style coil, it has power on one terminal and a switched ground to make it fire. If you're following along, you will remember the ECU puts out 5VDC. That's not going to work with a 2 wire coil. Keyswtched battery power is applied to one side of the coil. The output from the drivers connect to the other terminal. The drivers I installed essentially convert the 5VDC signal to a ground signal with the same varying duty cycle based upon your settings.

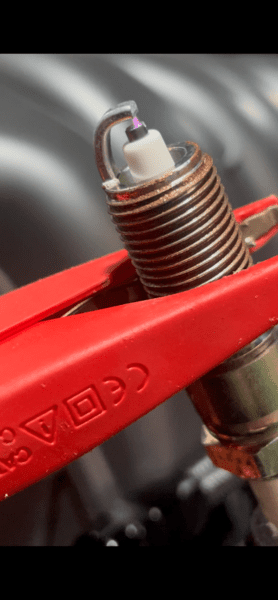

Once I got the drivers installed, it was time to power up the engine for the first time and start checking sensors, coils, and injectors. Since I made the wiring harness exactly the same as the small block, I started with the same tune and just started making changes from there. I figured this would be easier than starting from scratch. So far it looks like everything is working as it should. I only made it through checking about half of the things. All of the injectors fire properly and the water temp, MAP, and TPS are reading correctly based on the tuning software dashboard. I need to pull every coil to test each one individually. I did test #1 coil before heading in for the night and the coil drivers appear to work.

Once I get through all the coils, I'll setup the IAC, then confirm all the analog sensors are really correct, which I'm sure they are. After than, I'll crank the engine over to make sure I'm seeing the crank and cam signal. If all that checks out, it will be time to put the fuel pump relay in and make some noise!

For those not knowing or understanding why I needed to install coil drivers, I thought I'd explain it. I was previously running LS style coils. LS coils are considered "smart" coils, meaning they have their own driver inside them. There are 4 wires for each coil. Power, engine block ground, ECU signal ground, and ECU logic signal to fire the coil. The logic signal from the ECU is 5VDC based upon duty cycle.

The Hemi coil is only 2 wires. Just like your old school canister style coil, it has power on one terminal and a switched ground to make it fire. If you're following along, you will remember the ECU puts out 5VDC. That's not going to work with a 2 wire coil. Keyswtched battery power is applied to one side of the coil. The output from the drivers connect to the other terminal. The drivers I installed essentially convert the 5VDC signal to a ground signal with the same varying duty cycle based upon your settings.

Once I got the drivers installed, it was time to power up the engine for the first time and start checking sensors, coils, and injectors. Since I made the wiring harness exactly the same as the small block, I started with the same tune and just started making changes from there. I figured this would be easier than starting from scratch. So far it looks like everything is working as it should. I only made it through checking about half of the things. All of the injectors fire properly and the water temp, MAP, and TPS are reading correctly based on the tuning software dashboard. I need to pull every coil to test each one individually. I did test #1 coil before heading in for the night and the coil drivers appear to work.

Once I get through all the coils, I'll setup the IAC, then confirm all the analog sensors are really correct, which I'm sure they are. After than, I'll crank the engine over to make sure I'm seeing the crank and cam signal. If all that checks out, it will be time to put the fuel pump relay in and make some noise!

JBrian

Well-Known Member

I think your fuel table maybe close, but you can see the A/F to confirm before driving if you fire it on jack stands. However, timing needs to backed way down from an LA. My max timing under load above about 5000RPM is 22. It varies based on load. Let me know if you want to discuss before start up.Ended up getting the coil drivers installed last night. It wasn't as time consuming as I thought it would be. Taking the seat out helped make work under the dash easier.

For those not knowing or understanding why I needed to install coil drivers, I thought I'd explain it. I was previously running LS style coils. LS coils are considered "smart" coils, meaning they have their own driver inside them. There are 4 wires for each coil. Power, engine block ground, ECU signal ground, and ECU logic signal to fire the coil. The logic signal from the ECU is 5VDC based upon duty cycle.

The Hemi coil is only 2 wires. Just like your old school canister style coil, it has power on one terminal and a switched ground to make it fire. If you're following along, you will remember the ECU puts out 5VDC. That's not going to work with a 2 wire coil. Keyswtched battery power is applied to one side of the coil. The output from the drivers connect to the other terminal. The drivers I installed essentially convert the 5VDC signal to a ground signal with the same varying duty cycle based upon your settings.

Once I got the drivers installed, it was time to power up the engine for the first time and start checking sensors, coils, and injectors. Since I made the wiring harness exactly the same as the small block, I started with the same tune and just started making changes from there. I figured this would be easier than starting from scratch. So far it looks like everything is working as it should. I only made it through checking about half of the things. All of the injectors fire properly and the water temp, MAP, and TPS are reading correctly based on the tuning software dashboard. I need to pull every coil to test each one individually. I did test #1 coil before heading in for the night and the coil drivers appear to work.

Once I get through all the coils, I'll setup the IAC, then confirm all the analog sensors are really correct, which I'm sure they are. After than, I'll crank the engine over to make sure I'm seeing the crank and cam signal. If all that checks out, it will be time to put the fuel pump relay in and make some noise!

View attachment 1716255800

I knocked 15% fuel out of the whole fuel table since the engine is 15% smaller in displacement. No idea if that has any relevance, but figured it would be a good place to start. For the timing table, I found a few examples online and made some things up based on those tables. It's pretty conservative right now.I think your fuel table maybe close, but you can see the A/F to confirm before driving if you fire it on jack stands. However, timing needs to backed way down from an LA. My max timing under load above about 5000RPM is 22. It varies based on load. Let me know if you want to discuss before start up.

I finished checking all the coils and all are correct. Also started messing with the IAC, which in my mind is the biggest PIA out of all the things. I bet I spent more time tuning that thing than the damn fuel tables.

It runs! My gates heat shrink hose clamps didn’t show up so I could run it for very long. I put 2 gallons of coolant in it and it still isn’t even up to the water pump. That was enough for me to run a couple minutes.

That single big throttle body sure makes throttle response snappy. It’s pretty damn loud with open headers too.

For the engine gurus, I put the high pressure spring in the oil pump. It has over 100psi oil pressure when running. Is that bad?

That single big throttle body sure makes throttle response snappy. It’s pretty damn loud with open headers too.

For the engine gurus, I put the high pressure spring in the oil pump. It has over 100psi oil pressure when running. Is that bad?

Looking great and clean mate i am a still a long way off here as only at paint stage lol Just collecting all the parts for the swap which is slow given i am in Australia.

Have you hidden your headlight wiring loom or is it not currently installed?

Have you hidden your headlight wiring loom or is it not currently installed?

Last edited:

The headlight, horn, and fan wiring is all in the driver side fender well. I attached some P clamps with nuts to the bottoms of the fender bolts to hold the wiring up.Looking great and clean mate i am a still a long way off here as only at paint stage lol Just collecting all the parts for the swap which is slow given i am in Australia.

Have you hidden your headlight wiring loom or is it not currently installed?

AC and heater hoses are in the passenger side fender well held in the same manner.

@Dantra I wiped the white printing off the gates shrink clamps with lacquer thinner. It came off with zero effort.I used the Gates 32925 for the heater hoses.. 15/16 - 1-1/16. Th only thing I don't care for is the white printing on them. I suppose I could mask it with something

Grainger was the cheapest place, ironically. I have free shipping with them, so I saved a few bucks

O good idea on the P clamps i figured they were ran in there, shame they have no inner guard to protect it all. Love a nice clean bay especially with a swapThe headlight, horn, and fan wiring is all in the driver side fender well. I attached some P clamps with nuts to the bottoms of the fender bolts to hold the wiring up.

AC and heater hoses are in the passenger side fender well held in the same manner.

I have them wrapped with techflex wire loom to protect them. No issues yet!O good idea on the P clamps i figured they were ran in there, shame they have no inner guard to protect it all. Love a nice clean bay especially with a swap

My gates hose clamps came in Saturday so I was able to get the heater hoses and power steering suction line completed and get fluids topped off. I ran the car on and off for about an hour until my wife had enough of the open headers. Apparently it was rattling the walls in the house. Hmmm, I didn't notice... I'll get the exhaust back on before I run it again for any length of time. Ultimately the exhaust is the last big thing to get done.

I welded the IAT bung in the intake tube along and a piece of flat bar that I will use to attach a bracket to hold it up. Still need to Cerakote the tube, the rain has been ridiculous here so I couldn't get that done. I'll get some final pics once I get everything tidied up.

One thing that I noticed while running the engine was how much better the engine cooled. Once the radiator fans kicked on, the temperature almost immediately dropped low enough for them to turn off. I don't know if its the more efficient cooling system of the engine, or the double pass radiator. Perhaps its a combination of both. My 408 would just hold temp when idling and not moving, not drop temp! Looks like I'll be good for the 100 degree days in traffic with the AC on.

As I mentioned above, the IAC is a Pain in the *** to get set right. I don't know if its a megasquirt thing or not, but it just sucks. The big part is, there's not feedback on them, so the computer doesn't know what position it is in. There's lots of moving it in and out and unplugging and reinstalling... I did some fiddling with it yesterday without the engine running and I think it should be good now. When I was finally able to get the idle down to 800-900 RPM the cam sounds like it will have a decent lope. If its too much, I'll tone it down with some idle advance settings. All that's required to tone it down is to retard timing when the RPM increases, and advance it when it drops. You can also make a cam sound more aggressive doing the this. None of those advanced settings are active right now.

I welded the IAT bung in the intake tube along and a piece of flat bar that I will use to attach a bracket to hold it up. Still need to Cerakote the tube, the rain has been ridiculous here so I couldn't get that done. I'll get some final pics once I get everything tidied up.

One thing that I noticed while running the engine was how much better the engine cooled. Once the radiator fans kicked on, the temperature almost immediately dropped low enough for them to turn off. I don't know if its the more efficient cooling system of the engine, or the double pass radiator. Perhaps its a combination of both. My 408 would just hold temp when idling and not moving, not drop temp! Looks like I'll be good for the 100 degree days in traffic with the AC on.

As I mentioned above, the IAC is a Pain in the *** to get set right. I don't know if its a megasquirt thing or not, but it just sucks. The big part is, there's not feedback on them, so the computer doesn't know what position it is in. There's lots of moving it in and out and unplugging and reinstalling... I did some fiddling with it yesterday without the engine running and I think it should be good now. When I was finally able to get the idle down to 800-900 RPM the cam sounds like it will have a decent lope. If its too much, I'll tone it down with some idle advance settings. All that's required to tone it down is to retard timing when the RPM increases, and advance it when it drops. You can also make a cam sound more aggressive doing the this. None of those advanced settings are active right now.

-