Daniel Dugas

Well-Known Member

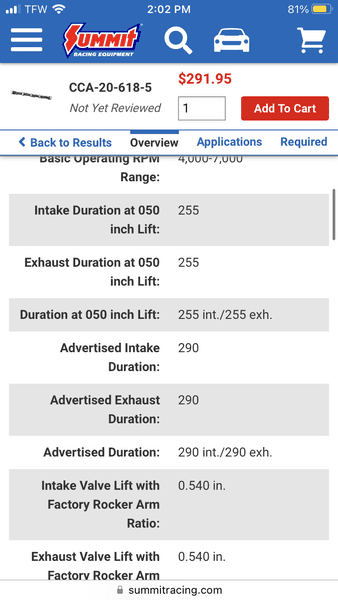

Alright guys need a little help here. So I have a mechanical flat tappet cam from comp. I’m a little nervous about Running it with all the issues with comp. Am I okay or should I find a different brand? -Thanks

Alright guys need a little help here. So I have a mechanical flat tappet cam from comp. I’m a little nervous about Running it with all the issues with comp. Am I okay or should I find a different brand? -Thanks

Comp can give you .904 specific lobes if you request them. This is not a problem. Seldom do I see a need to make an attempt and actually take max advantage of the larger diameter.Buy the edm lifters, oil holes that cool lifter face.

I've run them on 2 solid flats, I would recommend howards or Hughes over comp also. 100% better camshafts with Chrysler specific ramps

Yeah I'd rather give my money to someone who thinks Chrysler and not like " oh yeah don't forget Chrysler" lol.Comp can give you .904 specific lobes if you request them. This is not a problem. Seldom do I see a need to make an attempt and actually take max advantage of the larger diameter.

I was actually going to run the Howard’s direct lube lifters with that camBuy the edm lifters, oil holes that cool lifter face.

I've run them on 2 solid flats, I would recommend howards or Hughes over comp also. 100% better camshafts with Chrysler specific ramps

Yeah I'd rather give my money to someone who thinks Chrysler and not like " oh yeah don't forget Chrysler" lol.

Regardless of manufacturer, I would check every lobe and lifter before installing. Junk liftersI was actually going to run the Howard’s direct lube lifters with that cam

Who's EDM lifters do you go with?Buy the edm lifters, oil holes that cool lifter face.

I've run them on 2 solid flats, I would recommend howards or Hughes over comp also. 100% better camshafts with Chrysler specific ramps

Great idea !!!I was actually going to run the Howard’s direct lube lifters with that cam

I've used howards And hughes, not sure who they get them from.Who's EDM lifters do you go with?

Machine shops (at least in Denver, CO) know about the flat tappet issue and will not warranty the parts/labor on a wiped out cam.Have an/your automotive machinist check and install the cam. Let it be his responsibility.

My boss isn't that smart. He still uses comp flat tappet all the timeMachine shops (at least in Denver, CO) know about the flat tappet issue and will not warranty the parts/labor on a wiped out cam.