Remember many of these heads are on 4.100 or bigger bores.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

W5 heads

- Thread starter tvt59

- Start date

-

It is currently 4.185" bore. But it's got some wear on it. I'm going to get it sonic checked. If it'll go 4.220 I think that's what I'm going to do.Remember many of these heads are on 4.100 or bigger bores.

It is currently 4.185" bore. But it's got some wear on it. I'm going to get it sonic checked. If it'll go 4.220 I think that's what I'm going to do.

What size bore did Brett flow test them on.

I don't think that he has put them on the flow bench yet.What size bore did Brett flow test them on.

He did mine on a 4.185

Newbomb Turk

Well-Known Member

Remember many of these heads are on 4.100 or bigger bores.

I ran a 2.100 valve on a 4.04 bore. That's right at 52% of bore diameter.

I ran a 2.100 valve on a 4.04 bore. That's right at 52% of bore diameter.

I run a 2.08 valve on a 4.030 bore and use a 4.015 bore on my flowbench.

Newbomb Turk

Well-Known Member

I run a 2.08 valve on a 4.030 bore and use a 4.015 bore on my flowbench.

That's about 51.65% of bore diameter. about as close as you can get to 52% without being exactly 52%.

Pretty spanky.

That's about 51.65% of bore diameter. about as close as you can get to 52% without being exactly 52%.

Pretty spanky.

Come to think of it I’ve pushed that flow bench bore just a little more. I tested my 360-1 Indy heads on it with a 2.10 valve.

just curious on how wide your sweep pattern is .

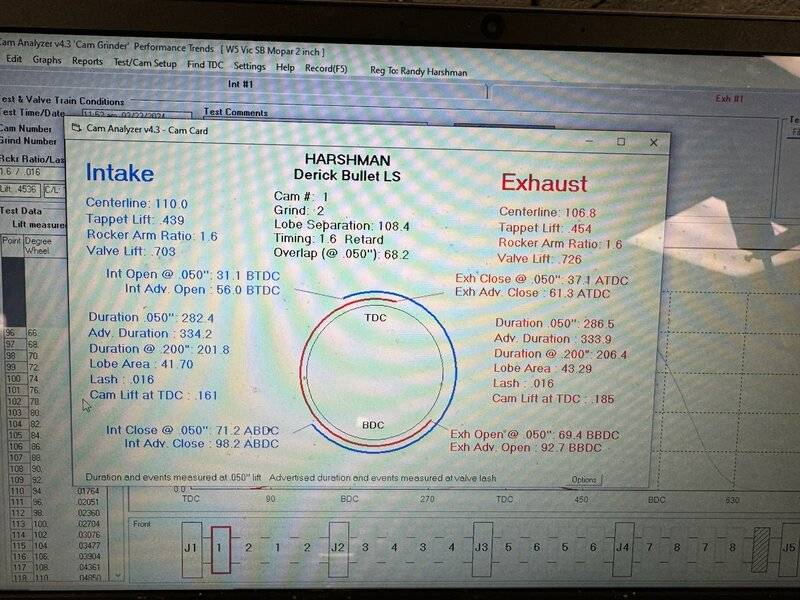

Cam for the W5 engine.Cam is supposed to be really good with these heads on alcohol fuel. Probably not very good on gasoline. But I hardly ever run gasoline anymore. I've updated. The specs. BTW we are using 1 75 ratio rocker arms

Last edited:

I can’t see how a cam is good for one fuel and not another.

Compression ratio - sure.

Compression ratio - sure.

Too be honest with you. I don't understand all of the dynamics. As explained to me. It has something to do with emptying the cylinder. But that's what I was informed. I guess we'll see.I can’t see how a cam is good for one fuel and not another.

Compression ratio - sure.

Brett said that the ports sounded really good when he checked them. Larry Smith did the porting. Brett was very complimentary of his work.

View attachment 1716225740

Is these after the 2.15 valves were installed

I always did like that guy 80% of the time. I’m not an easy guy to like because I speak my piece, and so does he.

Yeah, you guys are both good guys in my book.I always did like that guy 80% of the time. I’m not an easy guy to like because I speak my piece, and so does he.

Very helpful dudes.

I understand Top Fuel is totally different, but they have to open the exhaust valve vary late cause the pressure so high it would destroy the valvetrain if they tried to open it early. Not saying this is what's happening with alcohol but image there could be some effect the cam has to compensate for.I can’t see how a cam is good for one fuel and not another.

Compression ratio - sure.

Maybe you guys can have a 3 way group hug. lol

LolMaybe you guys can have a 3 way group hug. lol

Very nice. They look like they went a little further than mine did.

-