In this chapter I am going to go through checking the piston to valve clearance... In the last chapter I showed you how to install the timing chain... Now it's time to check the piston to valve clearance...

This is the next step to continue after Sections 1 - 10A... If you missed one of them, you can find it here...

How to Rebuild a Small Block Part 1: Block Prep

How to Rebuild a Small Block Part 2: Cam Bearing Install

How to Rebuild a Small Block Part 3: Install Water Jacket and Oil Galley Plugs

How to Rebuild a Small Block Part 4: Pre Flight Inspection After Machine Shop Before Assembly

How to Rebuild a Small Block Part 5: Crankshaft Install

How to Rebuild a Small Block Part 6: Installing Rings on Pistons

How to Rebuild a Small Block Part 7: Install Pistons in Block

How to Rebuild a Small Block Part 7a (Optional): CC the Engine Cylinder to Find Compression

How to Rebuild a Small Block Part 8: Install the Camshaft

How to Rebuild a Small Block Part 9: Install Camshaft Thrust Plate

How to Rebuild a Small Block Part 9A (Optional): Timing Chain Options

How to Rebuild a Small Block Part 10: Install Timing Chain

*************************************************************************

Hello everyone, it's Krazykuda here to show you how to rebuild a small block... This article is to help any newbies through rebuilding a small block Mopar LA engine, but may have a few tips that some of you seasoned builders may find useful... If you haven't ever built an engine, I will show you what you need to know to do it yourself...

The goal of this series is to show what you can do at home in your own garage... Go at your own pace and ability and then take it to someone knowledgeable for what you are not capable of doing yourself or don't have the proper equipment/tools for...

Keep checking back in from time to time as this is a work in progress and I plan to keep updating it as I build more engines and can show you more variations...

I am going to break this into sections that you can follow along with and make sense to do in 'stages' when you build... Plus you can then jump to the section that you are working on to help keep from sorting through one very long thread to find what part that you are working on when you are doing it....

*************************************************************************

*** Important Note *** Sometimes things may not go right and you will run into a snag/road block... Do not get in a hurry to finish and take short cuts that may compromise your build...

Step back, take a break, and think about it for a while... Or seek help from other experienced people or professionals to overcome the problem... Do it right and don't take any unnecessary chances that may compromise the integrity of your build...

If you don't fix the problem correctly, it may come back to haunt you and cost even more time and money than if you took the time to think about it and research it to fix the problem correctly...

This has been a public service announcement from krazykuda....

*************************************************************************

Now that you have installed the timing chain in chapter 10 and/or degreed the cam in chapter 10A , it's time to check piston-to-valve clearance... I recommend doing this whether you degreed the cam or not because it is important to have proper clearance between the piston to the valve... This should be done AFTER you get the cam degreed as degreeing the cam can affect the clearance... If the piston hits the valve, you can do damage to your engine ranging from; bending a pushrod, bending a connecting rod and/or breaking a piston, or worst case putting a piston and rod through the side of the block (I've had this happen)... It's worth the time to verify you have the proper clearance between the piston and valve so you don't destroy your engine...

Install the head gasket and head, and tighten properly to spec as you can refer to in the head install chapter of my series...

I like to use the adjustable rocker arm, pushrod, and lifter from an early 64 - 67 273 engine... You only need one set of intake and exhaust rocker arms to use on #1 cylinder... Then adjust the rocker arms for zero clearance...

I like to slowly tighten the adjusting stud on the rocker arm while twisting the pushrod as I tighten it... When you get to the point where you can't spin the pushrod by hand, back off a smidge until you can spin it by hand with a slight resistance, then you have zero clearance and are using the full lift of the cam...

You will need to buy a spare head gasket identical to the one you are going to use on your build, for accurate results... Then get some clay, you can buy it at a good hobby shop or craft shop... I got mine from Michaels... Take the clay and put some on the top of the piston, enough to cover most of the piston... Then put the head and rocker arm on and turn the crank four to six revolutions to make sure you get a good reading... Keep in mind that two crank rotations is one cycle in a four stroke engine, so you have to do at least 2 crank revolutions for the intake and exhaust valves to open and make an indention in the clay...

Once you make the indention in the clay, then remove the rocker arm and head and carefully peel the clay off the top of the piston being careful not to squeeze it or change the thickness of the clay.. It may help to spray some penetrating oil on top of the piston and the valves to keep the clay from sticking to the parts... Then take the clay and cut it on the centerline of each valve impression (intake and exhaust), since that is the worst case for clearance...

The clay should look like this when you are at this step...

Then use a dial caliper or digital caliper to measure the thickness of the clay at the smallest point of the impression... Here's what the clay looks like...

Here's the exhaust valve on the outer side of the clay...

Exhaust valve on the center cut of the clay...

Intake valve on the center cut of the clay...

Intake valve on the outside cut of the clay...

Write down the measurements that you get from each slice of the clay...

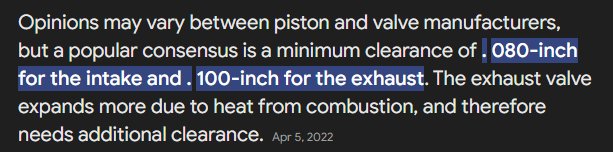

Here is the recommended minimum piston to valve clearance from the Summit Racing web site...

What is piston to valve clearance? · Help Center

If your piston-to-valve clearance is too small, you need to make it within the recommended clearance to avoid damaging your engine...

Here are the options to increase your piston-to-valve clearance to get it into spec...

1. Degree the camshaft if the clearance not too far off.

2. Change to a smaller lift camshaft.

3. Choose a lower compression piston.

4. Have valve reliefs machined the pistons at a machine shop.

5. Use a thicker head gasket.

Now that you have checked your piston-to-valve clearance and it is within the minimum recommended clearance you are ready to move onto either installing the heads or timing chain cover and water pump... I will do the heads next since that chapter is needed to complete piston-to-valve clearance...

This is the next step to continue after Sections 1 - 10A... If you missed one of them, you can find it here...

How to Rebuild a Small Block Part 1: Block Prep

How to Rebuild a Small Block Part 2: Cam Bearing Install

How to Rebuild a Small Block Part 3: Install Water Jacket and Oil Galley Plugs

How to Rebuild a Small Block Part 4: Pre Flight Inspection After Machine Shop Before Assembly

How to Rebuild a Small Block Part 5: Crankshaft Install

How to Rebuild a Small Block Part 6: Installing Rings on Pistons

How to Rebuild a Small Block Part 7: Install Pistons in Block

How to Rebuild a Small Block Part 7a (Optional): CC the Engine Cylinder to Find Compression

How to Rebuild a Small Block Part 8: Install the Camshaft

How to Rebuild a Small Block Part 9: Install Camshaft Thrust Plate

How to Rebuild a Small Block Part 9A (Optional): Timing Chain Options

How to Rebuild a Small Block Part 10: Install Timing Chain

*************************************************************************

Hello everyone, it's Krazykuda here to show you how to rebuild a small block... This article is to help any newbies through rebuilding a small block Mopar LA engine, but may have a few tips that some of you seasoned builders may find useful... If you haven't ever built an engine, I will show you what you need to know to do it yourself...

The goal of this series is to show what you can do at home in your own garage... Go at your own pace and ability and then take it to someone knowledgeable for what you are not capable of doing yourself or don't have the proper equipment/tools for...

Keep checking back in from time to time as this is a work in progress and I plan to keep updating it as I build more engines and can show you more variations...

I am going to break this into sections that you can follow along with and make sense to do in 'stages' when you build... Plus you can then jump to the section that you are working on to help keep from sorting through one very long thread to find what part that you are working on when you are doing it....

*************************************************************************

*** Important Note *** Sometimes things may not go right and you will run into a snag/road block... Do not get in a hurry to finish and take short cuts that may compromise your build...

Step back, take a break, and think about it for a while... Or seek help from other experienced people or professionals to overcome the problem... Do it right and don't take any unnecessary chances that may compromise the integrity of your build...

If you don't fix the problem correctly, it may come back to haunt you and cost even more time and money than if you took the time to think about it and research it to fix the problem correctly...

This has been a public service announcement from krazykuda....

*************************************************************************

Now that you have installed the timing chain in chapter 10 and/or degreed the cam in chapter 10A , it's time to check piston-to-valve clearance... I recommend doing this whether you degreed the cam or not because it is important to have proper clearance between the piston to the valve... This should be done AFTER you get the cam degreed as degreeing the cam can affect the clearance... If the piston hits the valve, you can do damage to your engine ranging from; bending a pushrod, bending a connecting rod and/or breaking a piston, or worst case putting a piston and rod through the side of the block (I've had this happen)... It's worth the time to verify you have the proper clearance between the piston and valve so you don't destroy your engine...

Install the head gasket and head, and tighten properly to spec as you can refer to in the head install chapter of my series...

I like to use the adjustable rocker arm, pushrod, and lifter from an early 64 - 67 273 engine... You only need one set of intake and exhaust rocker arms to use on #1 cylinder... Then adjust the rocker arms for zero clearance...

I like to slowly tighten the adjusting stud on the rocker arm while twisting the pushrod as I tighten it... When you get to the point where you can't spin the pushrod by hand, back off a smidge until you can spin it by hand with a slight resistance, then you have zero clearance and are using the full lift of the cam...

You will need to buy a spare head gasket identical to the one you are going to use on your build, for accurate results... Then get some clay, you can buy it at a good hobby shop or craft shop... I got mine from Michaels... Take the clay and put some on the top of the piston, enough to cover most of the piston... Then put the head and rocker arm on and turn the crank four to six revolutions to make sure you get a good reading... Keep in mind that two crank rotations is one cycle in a four stroke engine, so you have to do at least 2 crank revolutions for the intake and exhaust valves to open and make an indention in the clay...

Once you make the indention in the clay, then remove the rocker arm and head and carefully peel the clay off the top of the piston being careful not to squeeze it or change the thickness of the clay.. It may help to spray some penetrating oil on top of the piston and the valves to keep the clay from sticking to the parts... Then take the clay and cut it on the centerline of each valve impression (intake and exhaust), since that is the worst case for clearance...

The clay should look like this when you are at this step...

Then use a dial caliper or digital caliper to measure the thickness of the clay at the smallest point of the impression... Here's what the clay looks like...

Here's the exhaust valve on the outer side of the clay...

Exhaust valve on the center cut of the clay...

Intake valve on the center cut of the clay...

Intake valve on the outside cut of the clay...

Write down the measurements that you get from each slice of the clay...

Here is the recommended minimum piston to valve clearance from the Summit Racing web site...

What is piston to valve clearance? · Help Center

If your piston-to-valve clearance is too small, you need to make it within the recommended clearance to avoid damaging your engine...

Here are the options to increase your piston-to-valve clearance to get it into spec...

1. Degree the camshaft if the clearance not too far off.

2. Change to a smaller lift camshaft.

3. Choose a lower compression piston.

4. Have valve reliefs machined the pistons at a machine shop.

5. Use a thicker head gasket.

Now that you have checked your piston-to-valve clearance and it is within the minimum recommended clearance you are ready to move onto either installing the heads or timing chain cover and water pump... I will do the heads next since that chapter is needed to complete piston-to-valve clearance...