In this chapter I am going to go through installing the camshaft in the block... In the last chapter I showed you how to install the camshaft... Now it's time to install the cam...

This is the next step to continue after Sections 1 - 8... If you missed one of them, you can find it here...

How to Rebuild a Small Block Part 1: Block Prep

How to Rebuild a Small Block Part 2: Cam Bearing Install

How to Rebuild a Small Block Part 3: Install Water Jacket and Oil Galley Plugs

How to Rebuild a Small Block Part 4: Pre Flight Inspection After Machine Shop Before Assembly

How to Rebuild a Small Block Part 5: Crankshaft Install

How to Rebuild a Small Block Part 6: Installing Rings on Pistons

How to Rebuild a Small Block Part 7: Install Pistons in Block

First time builders may want to skip this one, but the more advanced ones may want to try it...

How to Rebuild a Small Block Part 7a (Optional): CC the Engine Cylinder to Find Compression

How to Rebuild a Small Block Part 8: Install the Camshaft

*************************************************************************

Hello everyone, it's Krazykuda here to show you how to rebuild a small block... This article is to help any newbies through rebuilding a small block Mopar LA engine, but may have a few tips that some of you seasoned builders may find useful... If you haven't ever built an engine, I will show you what you need to know to do it yourself...

The goal of this series is to show what you can do at home in your own garage... Go at your own pace and ability and then take it to someone knowledgeable for what you are not capable of doing yourself or don't have the proper equipment/tools for...

Keep checking back in from time to time as this is a work in progress and I plan to keep updating it as I build more engines and can show you more variations...

I am going to break this into sections that you can follow along with and make sense to do in 'stages' when you build... Plus you can then jump to the section that you are working on to help keep from sorting through one very long thread to find what part that you are working on when you are doing it....

*************************************************************************

*** Important Note *** Sometimes things may not go right and you will run into a snag/road block... Do not get in a hurry to finish and take short cuts that may compromise your build...

Step back, take a break, and think about it for a while... Or seek help from other experienced people or professionals to overcome the problem... Do it right and don't take any unnecessary chances that may compromise the integrity of your build...

If you don't fix the problem correctly, it may come back to haunt you and cost even more time and money than if you took the time to think about it and research it to fix the problem correctly...

This has been a public service announcement from krazykuda....

*************************************************************************

Now that the camshaft is installed, the next thing to install the camshaft thrust plate...

Before installing the thrust plate you need to make sure that the oil galley plugs for the lifter galley are installed... These are important for proper oil pressure...

On my first engine build the machine shop left these out and I was not aware of them being a new builder... After I built the engine and first start it had 25 - 30 psi cold and dropped down to 10 psi when it warmed up... I pulled the engine 4 times before finally finding the problem - the oil galley plugs behind the camshaft thrust plate were not installed... When I spun the engine with my home made oil priming shaft (they were not available back then) it was fine... But when my brother cam into the garage and saw the drill with the shaft he had to play with it and when he spun the drill a jet of oil shot out of the front of the engine 6 feet at me... Since the oil didn't shoot out when I did it, but when my brother did shows that it could be intermittent, however is important to have in those times that it would shoot out which would lead to a large pressure drop... After installing the oil galley plugs and reassembling the engine, it had 65 psi warm...

I've had some people tell me that they are not important as they are covered by the camshaft thrust plate, but that experience proved that they are... So if you are one of those that say you don't need them, you build your engine the way you want, but if you have low oil pressure don't come crying to me... My experience proved to me that you need them and I always make sure that all of the engines that I build have them... Installing two cup plugs now when you are building the engine is easier than having to go back into the engine and put them in later...

Here are the plugs that I am referring to...

This engine doesn't have them, so of course I installed them when I put it together...

Do not use any sealant on them like RTV as you don't want any of the excess coming off and getting into the oil system... This is after the oil filter and could damage some bearings, so only use penetrating oil like WD-40 to help them go in without galling... Then after installing them taking a flat blade screwdriver and making stakes in the plugs will also help make sure that they are in good and tight and will not come out... Like this...

The oil galley plugs come in this freeze plug kit from Mancini Racing...

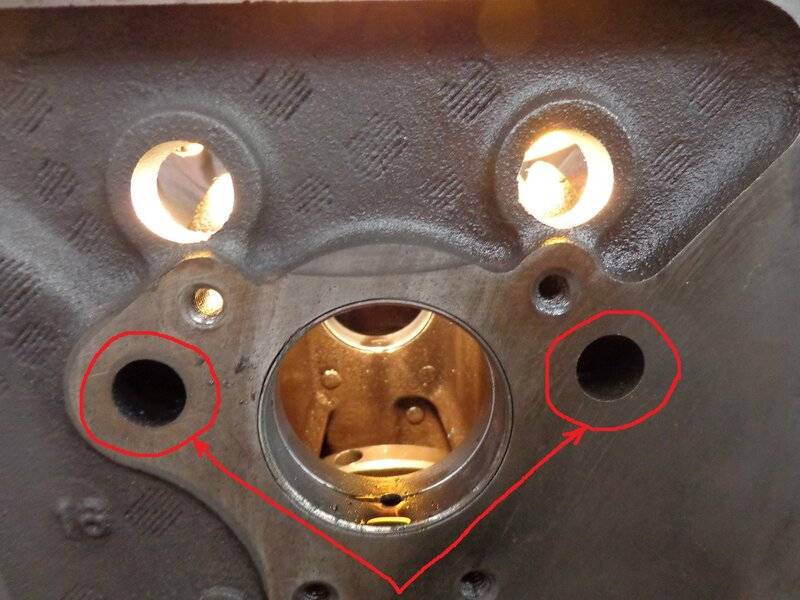

I want to point out that the top left bolt hole for the thrust plate is the passage for the oil to feed onto the timing chain from the intake valley of the block... I do not recommend using a standard bolt here as it will keep the oil from dripping from the intake valley into the front of the engine which oils the timing chain... The factory used a special bolt with a hole drilled through the middle to allow the oil to feed onto the timing chain oiling tab...

Here I put a light inside the intake valley so you can see the light coming through the bolt hole...

Here is the hole from inside the intake valley...

When the engine runs, the oil puddles in this valley and spills into the front of the engine...

Here are the bolts for the camshaft thrust plate... There should be two like the one on the right and the one on the left is the special factory bolt with the hole drilled through it...

Here's a close up of the factory bolt with the hole through it...

Here is the camshaft thrust plate... This is the front side that goes away from the block...

Here is the back side that goes against the block... You can tell by the two recessed circular holes on each ear under the top bolt holes...

The oil tab goes to the bottom two bolts of the thrust plate, this takes the dripping oil from the feed hold and directs it to drip directly onto the timing chain...

It uses this bolt to hold it in...

If you don't have the oiling tab, it comes in this block hardware kit from Mancini Racing along with the cam keyway, crank keyway, head dowel pins, camshaft 'washer' and bolt, and thrust plate bolts...

Comp Cams Engine Finishing Kit

*************************************************************************

Option A:

Now here is the usual way that I've seen from the factory and the way that I prefer to attach the oiling tab to the engine with the hole for the oil feed hole...

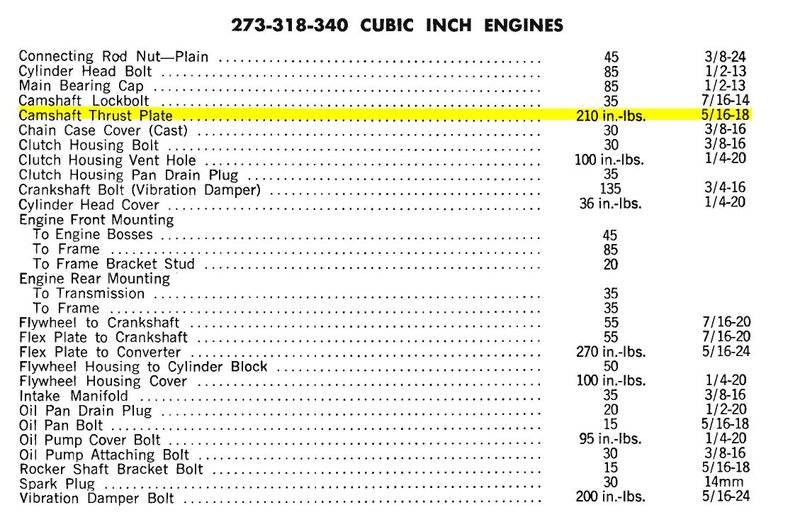

Tighten the bolts to 210 inch-pounds with an inch-pound torque wrench... Pull gently and evenly when torquing bolts for proper torque... Fast and hard pull or 'snapping it' will not give accurate torque...

Here's the torque spec from the 68 Plymouth manual...

*************************************************************************

Option B:

Now if you don't have one of the factory bolts with the hole drilled through the middle and you have some basic fabbing skills, here's one option that I did on one of my engines... Open up the bottom right hole in the thrust plate an extra 1/8" with a drill... Then take the oiling tab and make the tab fit the hole... This required me to make slit in the tab to allow me to bend it to fit in the larger hole and then take a punch and make the tab fit the outside of the opened hole without blocking the bolt from going through... You will also have to trim the back of the tab when you do this so it doesn't stick past the back of the thrust plate and interfere with the threads in the block... I mounted the thrust plate and tab on an old junk block to use the punch on for the modification so I didn't mess up the hole on my good block...

This way you can have three bolts holding the thrust plate on the engine... I do not trust using only two bolts on the thrust plate...

Here's how it turned out...

Here it is with a bolt in it... This way you just leave the top left bolt hole open for the oil to come through...

Now the camshaft thrust plate is properly installed, you are ready to move onto the next article on timing chain installation...

This is the next step to continue after Sections 1 - 8... If you missed one of them, you can find it here...

How to Rebuild a Small Block Part 1: Block Prep

How to Rebuild a Small Block Part 2: Cam Bearing Install

How to Rebuild a Small Block Part 3: Install Water Jacket and Oil Galley Plugs

How to Rebuild a Small Block Part 4: Pre Flight Inspection After Machine Shop Before Assembly

How to Rebuild a Small Block Part 5: Crankshaft Install

How to Rebuild a Small Block Part 6: Installing Rings on Pistons

How to Rebuild a Small Block Part 7: Install Pistons in Block

First time builders may want to skip this one, but the more advanced ones may want to try it...

How to Rebuild a Small Block Part 7a (Optional): CC the Engine Cylinder to Find Compression

How to Rebuild a Small Block Part 8: Install the Camshaft

*************************************************************************

Hello everyone, it's Krazykuda here to show you how to rebuild a small block... This article is to help any newbies through rebuilding a small block Mopar LA engine, but may have a few tips that some of you seasoned builders may find useful... If you haven't ever built an engine, I will show you what you need to know to do it yourself...

The goal of this series is to show what you can do at home in your own garage... Go at your own pace and ability and then take it to someone knowledgeable for what you are not capable of doing yourself or don't have the proper equipment/tools for...

Keep checking back in from time to time as this is a work in progress and I plan to keep updating it as I build more engines and can show you more variations...

I am going to break this into sections that you can follow along with and make sense to do in 'stages' when you build... Plus you can then jump to the section that you are working on to help keep from sorting through one very long thread to find what part that you are working on when you are doing it....

*************************************************************************

*** Important Note *** Sometimes things may not go right and you will run into a snag/road block... Do not get in a hurry to finish and take short cuts that may compromise your build...

Step back, take a break, and think about it for a while... Or seek help from other experienced people or professionals to overcome the problem... Do it right and don't take any unnecessary chances that may compromise the integrity of your build...

If you don't fix the problem correctly, it may come back to haunt you and cost even more time and money than if you took the time to think about it and research it to fix the problem correctly...

This has been a public service announcement from krazykuda....

*************************************************************************

Now that the camshaft is installed, the next thing to install the camshaft thrust plate...

Before installing the thrust plate you need to make sure that the oil galley plugs for the lifter galley are installed... These are important for proper oil pressure...

On my first engine build the machine shop left these out and I was not aware of them being a new builder... After I built the engine and first start it had 25 - 30 psi cold and dropped down to 10 psi when it warmed up... I pulled the engine 4 times before finally finding the problem - the oil galley plugs behind the camshaft thrust plate were not installed... When I spun the engine with my home made oil priming shaft (they were not available back then) it was fine... But when my brother cam into the garage and saw the drill with the shaft he had to play with it and when he spun the drill a jet of oil shot out of the front of the engine 6 feet at me... Since the oil didn't shoot out when I did it, but when my brother did shows that it could be intermittent, however is important to have in those times that it would shoot out which would lead to a large pressure drop... After installing the oil galley plugs and reassembling the engine, it had 65 psi warm...

I've had some people tell me that they are not important as they are covered by the camshaft thrust plate, but that experience proved that they are... So if you are one of those that say you don't need them, you build your engine the way you want, but if you have low oil pressure don't come crying to me... My experience proved to me that you need them and I always make sure that all of the engines that I build have them... Installing two cup plugs now when you are building the engine is easier than having to go back into the engine and put them in later...

Here are the plugs that I am referring to...

This engine doesn't have them, so of course I installed them when I put it together...

Do not use any sealant on them like RTV as you don't want any of the excess coming off and getting into the oil system... This is after the oil filter and could damage some bearings, so only use penetrating oil like WD-40 to help them go in without galling... Then after installing them taking a flat blade screwdriver and making stakes in the plugs will also help make sure that they are in good and tight and will not come out... Like this...

The oil galley plugs come in this freeze plug kit from Mancini Racing...

I want to point out that the top left bolt hole for the thrust plate is the passage for the oil to feed onto the timing chain from the intake valley of the block... I do not recommend using a standard bolt here as it will keep the oil from dripping from the intake valley into the front of the engine which oils the timing chain... The factory used a special bolt with a hole drilled through the middle to allow the oil to feed onto the timing chain oiling tab...

Here I put a light inside the intake valley so you can see the light coming through the bolt hole...

Here is the hole from inside the intake valley...

When the engine runs, the oil puddles in this valley and spills into the front of the engine...

Here are the bolts for the camshaft thrust plate... There should be two like the one on the right and the one on the left is the special factory bolt with the hole drilled through it...

Here's a close up of the factory bolt with the hole through it...

Here is the camshaft thrust plate... This is the front side that goes away from the block...

Here is the back side that goes against the block... You can tell by the two recessed circular holes on each ear under the top bolt holes...

The oil tab goes to the bottom two bolts of the thrust plate, this takes the dripping oil from the feed hold and directs it to drip directly onto the timing chain...

It uses this bolt to hold it in...

If you don't have the oiling tab, it comes in this block hardware kit from Mancini Racing along with the cam keyway, crank keyway, head dowel pins, camshaft 'washer' and bolt, and thrust plate bolts...

Comp Cams Engine Finishing Kit

*************************************************************************

Option A:

Now here is the usual way that I've seen from the factory and the way that I prefer to attach the oiling tab to the engine with the hole for the oil feed hole...

Tighten the bolts to 210 inch-pounds with an inch-pound torque wrench... Pull gently and evenly when torquing bolts for proper torque... Fast and hard pull or 'snapping it' will not give accurate torque...

Here's the torque spec from the 68 Plymouth manual...

*************************************************************************

Option B:

Now if you don't have one of the factory bolts with the hole drilled through the middle and you have some basic fabbing skills, here's one option that I did on one of my engines... Open up the bottom right hole in the thrust plate an extra 1/8" with a drill... Then take the oiling tab and make the tab fit the hole... This required me to make slit in the tab to allow me to bend it to fit in the larger hole and then take a punch and make the tab fit the outside of the opened hole without blocking the bolt from going through... You will also have to trim the back of the tab when you do this so it doesn't stick past the back of the thrust plate and interfere with the threads in the block... I mounted the thrust plate and tab on an old junk block to use the punch on for the modification so I didn't mess up the hole on my good block...

This way you can have three bolts holding the thrust plate on the engine... I do not trust using only two bolts on the thrust plate...

Here's how it turned out...

Here it is with a bolt in it... This way you just leave the top left bolt hole open for the oil to come through...

Now the camshaft thrust plate is properly installed, you are ready to move onto the next article on timing chain installation...