This chapter is optional for building an engine, that's why it has the A suffix in the title...

In this chapter I am going to explain the different timing chains available on the small block Mopar... In the last chapter I showed you how to install the camshaft and camshaft thrust plate... Here I'm going to explain the different timing chains and gears and the differences so you can choose the best one for your application...

This is the next step to continue after Sections 1 - 9... If you missed one of them, you can find it here...

How to Rebuild a Small Block Part 1: Block Prep

How to Rebuild a Small Block Part 2: Cam Bearing Install

How to Rebuild a Small Block Part 3: Install Water Jacket and Oil Galley Plugs

How to Rebuild a Small Block Part 4: Pre Flight Inspection After Machine Shop Before Assembly

How to Rebuild a Small Block Part 5: Crankshaft Install

How to Rebuild a Small Block Part 6: Installing Rings on Pistons

How to Rebuild a Small Block Part 7: Install Pistons in Block

First time builders may want to skip this one, but the more advanced ones may want to try it...

How to Rebuild a Small Block Part 7a (Optional): CC the Engine Cylinder to Find Compression

How to Rebuild a Small Block Part 8: Install the Camshaft

www.forabodiesonly.com

www.forabodiesonly.com

*************************************************************************

Hello everyone, it's Krazykuda here to show you how to rebuild a small block... This article is to help any newbies through rebuilding a small block Mopar LA engine, but may have a few tips that some of you seasoned builders may find useful... If you haven't ever built an engine, I will show you what you need to know to do it yourself...

The goal of this series is to show what you can do at home in your own garage... Go at your own pace and ability and then take it to someone knowledgeable for what you are not capable of doing yourself or don't have the proper equipment/tools for...

Keep checking back in from time to time as this is a work in progress and I plan to keep updating it as I build more engines and can show you more variations...

I am going to break this into sections that you can follow along with and make sense to do in 'stages' when you build... Plus you can then jump to the section that you are working on to help keep from sorting through one very long thread to find what part that you are working on when you are doing it....

Any of my chapters with an 'A' suffix after the chapter number are good information to know, but not necessary in the basic assembly of the engine... The chapters that are solely dedicated to assembling the engine are straight numbers with no suffix... You can skip the chapters with the suffix if you are more interested in the actual assembly of the engine or are a first time builder and want to stick to the basic assembly... The chapters with suffixes that are for the more detail for someone that wants to do a more thorough job...

*************************************************************************

*** Important Note *** Sometimes things may not go right and you will run into a snag/road block... Do not get in a hurry to finish and take short cuts that may compromise your build...

Step back, take a break, and think about it for a while... Or seek help from other experienced people or professionals to overcome the problem... Do it right and don't take any unnecessary chances that may compromise the integrity of your build...

If you don't fix the problem correctly, it may come back to haunt you and cost even more time and money than if you took the time to think about it and research it to fix the problem correctly...

This has been a public service announcement from krazykuda....

*************************************************************************

Now that the camshaft thrust plate is installed, the next thing to install the timing chain...

First I would like to go through the different types of timing chains and gears available for the small block... There are three types of gears and chains available, the single row nylon tooth gear timing chain that came from the factory on 273 and 318 engines... (I'm not sure if it came on the 360's or not)... The next step up in quality and durability is the single row chain with metal gears without the plastic nylon coating...

Then you have the double roller timing chain and gears that was original on the 340's from the factory...

There is a true roller double roller that is just slightly better than the stock factory 340 timing chain - this one is the one I choose to use as it's the most durable and the price is reasonable for the quality and durability... It has a little less friction than the standard double roller and is a little stronger and more durable, I've run them over 130k miles on daily drivers and they are still within spec for chain stretch... As stated in earlier chapters, I like to build it right the first time with quality and durability the top priority over price - the quality is worth the cost...

Here are the three basic types of gears that are available for the small block, on the right is the double roller gear, in the middle is the single row metal gear, and on the right is the stock nylon covered tooth cam gear...

Here is the gear for the double roller timing chain:

Here is the metal gear for the single row timing chain that is not nylon covered:

Here are the double roller and single row steel gears side by side for comparison:

Here is the factory stock nylon covered tooth single row timing chain:

Here is the steel single row gear next to the nylon covered tooth single row gear for comparison:

*************************************************************************

Here's some pictures of the stock 273/318 single row nylon tooth timing chain showing how the plastic nylon coating on the gears gets hard and brittle and chips off the cam gear with age... The factory used these because they were trying to keep the noise down, however I've never I've never been able to hear any noise from one without the nylon coating... The pieces of nylon plastic that chip off the gear end up in the bottom of the oil pan and may come out with an oil change or not depending on how small the chips are...

Here's one on a 68 318 that I bought... I'm not sure if the chain jumped timing before I bought it or it fell off during playing on the engine stand, but you can see by how much nylon has chipped off the cam gear that the chain became very loose and it can jump a tooth or in extreme cases even fall off like this and the engine will die (but can be repaired with a new chain and gear set)... When they get this loose, you can see the timing mark jump back and forth when you put a timing light on to check the timing... This variation in timing will affect and decrease performance, efficiency, and economy...

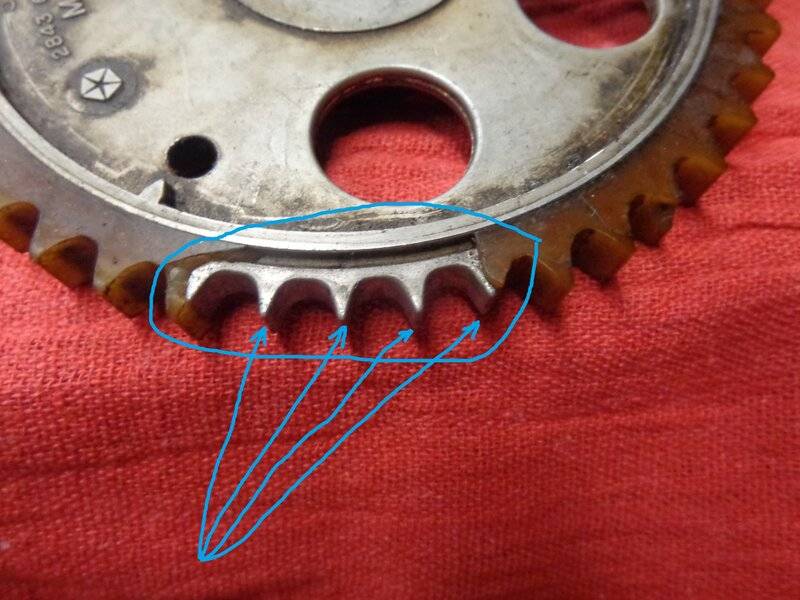

Here are some more detailed pictures of the gear from different angles showing the degree of chipping that can happen on an old chain that has been through many hot and cold cycles that makes the nylon very brittle and will chip off...

My first Barracuda that I drove in high school was a 68 fastback with 84,000 original miles... I was the second owner on it and I replaced the chain and gears with a factory style double roller and improved my economy 2 MPG and the timing light showed the timing was more stable and didn't jump back and forth when I had a timing light hooked up like it did with the original worn chain and gears...

In my opinion, these nylon covered gear chains are JUNK and I recommend replacing them if your engine has one... One of the first things that I do on a stock 273 or 318 with the original chain is replace it with one of the other options...

My timing chain of choice is the Edelbrock true roller double roller... I've been running it for decades and have put many happy miles on many engines with them... I rebuilt a 318 for my daily driver 68 barracuda fastback that I drove from 1996 to 2003 and when I refreshed the engine at 130,000 miles, the Edelbrock chain and gears were still good and tight without any excess play or slop in the chain... Since I had already bought a new one for $50 back then, I decided to just go with the new one since it wasn't too expensive and I wanted maximum mileage from the refreshed engine... I drove that engine to 500,000 miles with two refreshes...

*************************************************************************

Here is the timing chain that I've used for many years with no problems whatsoever... It will go well over 150,000 miles on a daily driver/cruiser and is a good bang for the buck... The Edelbrock true roller double roller:

It has three keyways machined into the crank gear so you can install/degree it straight up at 0°, or +/- 4° advanced or retarded to tune in your power band for your application...

In this chapter I am going to explain the different timing chains available on the small block Mopar... In the last chapter I showed you how to install the camshaft and camshaft thrust plate... Here I'm going to explain the different timing chains and gears and the differences so you can choose the best one for your application...

This is the next step to continue after Sections 1 - 9... If you missed one of them, you can find it here...

How to Rebuild a Small Block Part 1: Block Prep

How to Rebuild a Small Block Part 2: Cam Bearing Install

How to Rebuild a Small Block Part 3: Install Water Jacket and Oil Galley Plugs

How to Rebuild a Small Block Part 4: Pre Flight Inspection After Machine Shop Before Assembly

How to Rebuild a Small Block Part 5: Crankshaft Install

How to Rebuild a Small Block Part 6: Installing Rings on Pistons

How to Rebuild a Small Block Part 7: Install Pistons in Block

First time builders may want to skip this one, but the more advanced ones may want to try it...

How to Rebuild a Small Block Part 7a (Optional): CC the Engine Cylinder to Find Compression

How to Rebuild a Small Block Part 8: Install the Camshaft

How to Rebuild a Small Block Part 9: Install Camshaft Thrust Plate

In this chapter I am going to go through installing the camshaft in the block... In the last chapter I showed you how to install the camshaft... Now it's time to install the cam... This is the next step to continue after Sections 1 - 8... If you...

www.forabodiesonly.com

www.forabodiesonly.com

*************************************************************************

Hello everyone, it's Krazykuda here to show you how to rebuild a small block... This article is to help any newbies through rebuilding a small block Mopar LA engine, but may have a few tips that some of you seasoned builders may find useful... If you haven't ever built an engine, I will show you what you need to know to do it yourself...

The goal of this series is to show what you can do at home in your own garage... Go at your own pace and ability and then take it to someone knowledgeable for what you are not capable of doing yourself or don't have the proper equipment/tools for...

Keep checking back in from time to time as this is a work in progress and I plan to keep updating it as I build more engines and can show you more variations...

I am going to break this into sections that you can follow along with and make sense to do in 'stages' when you build... Plus you can then jump to the section that you are working on to help keep from sorting through one very long thread to find what part that you are working on when you are doing it....

Any of my chapters with an 'A' suffix after the chapter number are good information to know, but not necessary in the basic assembly of the engine... The chapters that are solely dedicated to assembling the engine are straight numbers with no suffix... You can skip the chapters with the suffix if you are more interested in the actual assembly of the engine or are a first time builder and want to stick to the basic assembly... The chapters with suffixes that are for the more detail for someone that wants to do a more thorough job...

*************************************************************************

*** Important Note *** Sometimes things may not go right and you will run into a snag/road block... Do not get in a hurry to finish and take short cuts that may compromise your build...

Step back, take a break, and think about it for a while... Or seek help from other experienced people or professionals to overcome the problem... Do it right and don't take any unnecessary chances that may compromise the integrity of your build...

If you don't fix the problem correctly, it may come back to haunt you and cost even more time and money than if you took the time to think about it and research it to fix the problem correctly...

This has been a public service announcement from krazykuda....

*************************************************************************

Now that the camshaft thrust plate is installed, the next thing to install the timing chain...

First I would like to go through the different types of timing chains and gears available for the small block... There are three types of gears and chains available, the single row nylon tooth gear timing chain that came from the factory on 273 and 318 engines... (I'm not sure if it came on the 360's or not)... The next step up in quality and durability is the single row chain with metal gears without the plastic nylon coating...

Then you have the double roller timing chain and gears that was original on the 340's from the factory...

There is a true roller double roller that is just slightly better than the stock factory 340 timing chain - this one is the one I choose to use as it's the most durable and the price is reasonable for the quality and durability... It has a little less friction than the standard double roller and is a little stronger and more durable, I've run them over 130k miles on daily drivers and they are still within spec for chain stretch... As stated in earlier chapters, I like to build it right the first time with quality and durability the top priority over price - the quality is worth the cost...

Here are the three basic types of gears that are available for the small block, on the right is the double roller gear, in the middle is the single row metal gear, and on the right is the stock nylon covered tooth cam gear...

Here is the gear for the double roller timing chain:

Here is the metal gear for the single row timing chain that is not nylon covered:

Here are the double roller and single row steel gears side by side for comparison:

Here is the factory stock nylon covered tooth single row timing chain:

Here is the steel single row gear next to the nylon covered tooth single row gear for comparison:

*************************************************************************

Here's some pictures of the stock 273/318 single row nylon tooth timing chain showing how the plastic nylon coating on the gears gets hard and brittle and chips off the cam gear with age... The factory used these because they were trying to keep the noise down, however I've never I've never been able to hear any noise from one without the nylon coating... The pieces of nylon plastic that chip off the gear end up in the bottom of the oil pan and may come out with an oil change or not depending on how small the chips are...

Here's one on a 68 318 that I bought... I'm not sure if the chain jumped timing before I bought it or it fell off during playing on the engine stand, but you can see by how much nylon has chipped off the cam gear that the chain became very loose and it can jump a tooth or in extreme cases even fall off like this and the engine will die (but can be repaired with a new chain and gear set)... When they get this loose, you can see the timing mark jump back and forth when you put a timing light on to check the timing... This variation in timing will affect and decrease performance, efficiency, and economy...

Here are some more detailed pictures of the gear from different angles showing the degree of chipping that can happen on an old chain that has been through many hot and cold cycles that makes the nylon very brittle and will chip off...

My first Barracuda that I drove in high school was a 68 fastback with 84,000 original miles... I was the second owner on it and I replaced the chain and gears with a factory style double roller and improved my economy 2 MPG and the timing light showed the timing was more stable and didn't jump back and forth when I had a timing light hooked up like it did with the original worn chain and gears...

In my opinion, these nylon covered gear chains are JUNK and I recommend replacing them if your engine has one... One of the first things that I do on a stock 273 or 318 with the original chain is replace it with one of the other options...

My timing chain of choice is the Edelbrock true roller double roller... I've been running it for decades and have put many happy miles on many engines with them... I rebuilt a 318 for my daily driver 68 barracuda fastback that I drove from 1996 to 2003 and when I refreshed the engine at 130,000 miles, the Edelbrock chain and gears were still good and tight without any excess play or slop in the chain... Since I had already bought a new one for $50 back then, I decided to just go with the new one since it wasn't too expensive and I wanted maximum mileage from the refreshed engine... I drove that engine to 500,000 miles with two refreshes...

*************************************************************************

Here is the timing chain that I've used for many years with no problems whatsoever... It will go well over 150,000 miles on a daily driver/cruiser and is a good bang for the buck... The Edelbrock true roller double roller:

It has three keyways machined into the crank gear so you can install/degree it straight up at 0°, or +/- 4° advanced or retarded to tune in your power band for your application...