Machmeter1

Well-Known Member

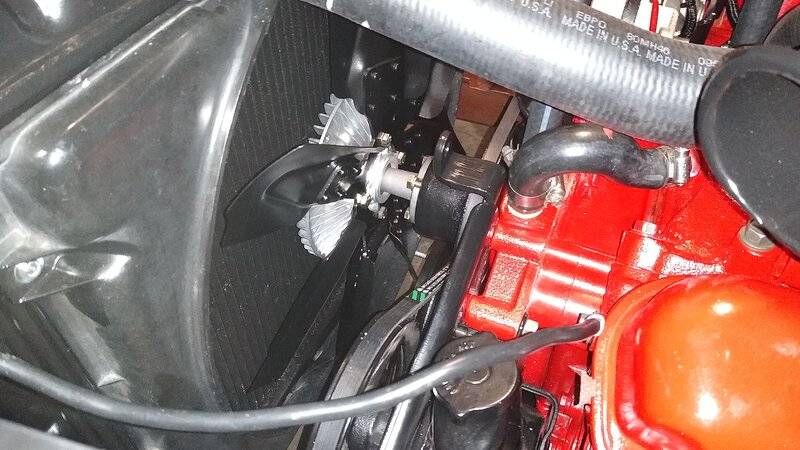

Clutch and Fan:

Thanks to a member on FBBO, I was able to acquire a correct 18” clutch fan #2863215 (the numbers can be found on every blade).

Even though the fan was in good condition, I measured and marked every blade on both planes and corrected some blades a few mm. Once the fan was again in perfect shape, it got bead blasted and painted.

Correct NOS fan clutches #2863266 are hard to find and if, quite expensive, so I went with an alternative: https://www.rockauto.com/en/moreinfo.php?pk=815318&jsn=656

To my luck, the previous owner preserved the original and correct 22” radiator and matching fan shroud.

The direct fan which was installed before is now up for sale.

Thanks to a member on FBBO, I was able to acquire a correct 18” clutch fan #2863215 (the numbers can be found on every blade).

Even though the fan was in good condition, I measured and marked every blade on both planes and corrected some blades a few mm. Once the fan was again in perfect shape, it got bead blasted and painted.

Correct NOS fan clutches #2863266 are hard to find and if, quite expensive, so I went with an alternative: https://www.rockauto.com/en/moreinfo.php?pk=815318&jsn=656

To my luck, the previous owner preserved the original and correct 22” radiator and matching fan shroud.

The direct fan which was installed before is now up for sale.

Last edited: