I’m bringing the Vitamin C Dart back home finally from body and paint. No wiring, dash, seats, engine or transmission installed. I won’t have much time to work on it until my wife is feeling better but it’s up to me now to finish.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1970 Swinger 340 resto

- Thread starter Spadman

- Start date

-

What a transformation. Dart looks great!

340sFastback

Well-Known Member

I love '70 Darts. Gonna be so worth it once done.

WOO HOO!!! Congratulations! I find it useful to make a "punch list" of things that need to be done. It keeps you on track and you get the satisfaction of crossing stuff off as you get to it. If you can just do a little bit on a regular basis, you'll make great progress.

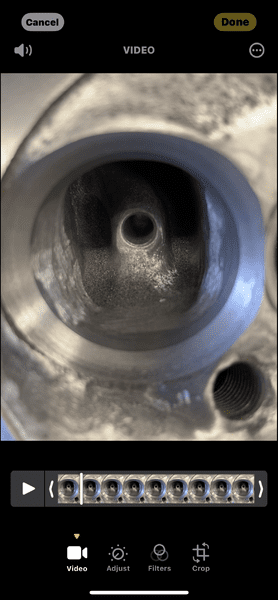

It’s been a while since I gave an update. Things went slow over the winter for lack of shop time. I spent about a month just getting a Harbor Freight blasting cabinet together with its million screws. It works good when I switched from walnut shells to sand. Still need to add more light. After blasting the side cover on my transmission I finished it and cleared the table for head work. Pictured is finished A833; blasting cabinet; and a semifinished combustion chamber on a 915 J head. I have milled them to 60 cc after cleanup and the quench pad is about 40 thou. I found a couple of places in Columbus OH that can do me a five angle valve job when I visit my sons later this month. I ordered Speedpro H116CP pistons for static compression close to 10.5. Using Wallace with 280 degree cam I will be under 165 cranking.

Last edited:

Not much to update but some slow progress. Got the valve job with a 70 degree throat cut and one head blended into the bowl. Gasket matched with radius of the pushrod pinch to the straight port wall. Still more work to do around the guide bosses and clean up the chambers a bit more. Guide cutter and seals to be delivered tomorrow to make room for the lift of my cam with 1.6 ratio. Of .506. Chamber finishing may get me to about 62cc and 10.25CR. Then I can finally put it all together.

Str12-340 suggested I make a punch list to mark off as I get things done. I took his advice and reviewed it lately. I was pleased to see quite a few items have gotten done though slowly. Thanks str12-340.

One item I’m pleased with is the finished heads were flow checked on one intake port by a local friend, engine builder and head porter. He got 261 cfm at .500 with same 261 at .600. This was my first port job so I am happy to have spent the time starting with stock cast J heads.

One item I’m pleased with is the finished heads were flow checked on one intake port by a local friend, engine builder and head porter. He got 261 cfm at .500 with same 261 at .600. This was my first port job so I am happy to have spent the time starting with stock cast J heads.

Fretting over little stuff. I’ve not posted an update since May 2024, as progress is very slow. However, I’ve enjoyed what little time I had in the shop in 2024. I’m trying to do the best job I can do and so keep adding new work. So much for “throwing in the already built 360”. I decided to go with higher compression pistons to complement the Direct Connection cam I already had. Then I did a ton more work to the heads. Then I decided to go with Mancini/HS 1.6 roller rockers to get my lift up to .500. Every single one of the hold downs had to be clearanced. Of course stock pushrods wouldn’t work any more so I cut a custom set from the Mancini kit. Next I turned to the old Direct Connection lifters that had been soaking for months to clean them up. Now I’m waiting for Crower to return from Christmas break to ship me some snap ring type retainers for the lifters. Meanwhile the intake has been machined to match the shaved heads. About there finally. Today I painted the oil filter 90 degree adapter. Maybe 2025 will finally see the car finished.

Last edited:

mygasser

Well-Known Member

nothing wrong with a bit of project creep, especially if you're not in a rush.

neil.

neil.

-